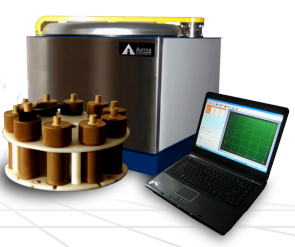

Microwave Digestion System -TRANSFORM 800

The TRANSFORM 800 Microwave Digestion System is a piece of analytical instrumentation. It features high-pressure capabilities to help reduce the amount of time needed for sample preparation. This top-loading, closed-vessel device also works to enhance the quality of the prepared samples.

The TRANSFORM 800 Microwave Digestion Instrument can simultaneously run up to 10 high-pressure closed vessels in its rotating carousel—this ensures even temperature and pressure distribution. This particular Microwave Digestion Device has the capacity for fast, pre-programmed digestion for even the most difficult samples. Featuring one-step operational capabilities, as well as full software control of temperature and power, this instrument complements your Atomic Absorption Spectrometer (AAS), ICP-AES, and ICP-MS applications. It also leads the way in optimum performance and industrial safety.

- Description

- Additional information

Description

HIGHLIGHTS

The innovative pressure sensor technology of the TRANSFORM 800 provides the most accurate pressure range possible.

Combined with the temperature probe, the pressure sensor ensures that users have complete control of reaction conditions.

The advanced thermocouple probe enables fast and accurate temperature control and sensing.

The TRANSFORM Series provides unparalleled safety, reproducible measurements and ease of operation.

| Number of Vessels | 10 (9 standard+1 sensor vessel) |

| Operating Pressure | 800 psi |

| Operating Temperature | 250°C |

| Temperature Sensor | 1 |

| Pressure Sensor | 1 |

| Microwave Power | 1200 W |

| Magnetron Frequency | 2450 Mhz |

| Dimensions (cm) W x D x H | 48 x 55 x 48 |

| Weight | 50 kg |

| Direct sensing and control of sample temperature, and monitoring of pressure in vessels to ensure reproducible digestion. | |

| Evenly distributed microwave field throughout the chamber ensures uniform heat for each vessel. | |

| On-line EPA protocols and methods directory, offering full compliance with EPA methods. | |

| Flexibility to program individual methods for specific customizable sample preparation. | |

| Automated recording of conditions during each digestion reduces volatile element loss. | |

| Prevents sample containment from the environment. | |

| Minimizes solvent consumption | |

| Safety features | |

| + Round, pressure-resistant heavy-duty oven chamber made of PFA-coated stainless steel. | |

| + Top-loading, heavy duty automatic door with three level protection and safety interlocks. | |

| + Spring loaded inner cavity of lid buffers the shock in the event of heightened pressure. | |

| + Over Pressure Valve on each vessel vents at pre-set pressure limits. In addition, each vessel also has a rupture disk, offering the highest level of safety for high-pressure situations. | |

| + Residual vessel pressure can be released manually during opening, providing extra safety to the user. | |

| + Digestion vessels are molded with engineering plastics. | |

| + Continuous temperature control and pressure monitoring. |

| Supply Power | 220 V, 50/60 Hz, 10 A |

| Featuring one-step operational capabilities, as well as full software control of temperature and power, this instrument complements your Atomic Absorption Spectrometer (AAS), ICP-AES, and ICP-MS applications |

| Food agricultural fishing: seafood, seeds, poultry. |

| Environmental: wastewater, soil & sludge, crude oil. |

| Electronics manufacturing textile: toys, cotton, plastics. |

| Petrochemical minerals metallurgical: rocks & minerals, steel & alloys, metals. |

| Medical biological pharmaceutical: blood & urine, animal tissue & fluids, drug tablets. |

Updating…

The TRANSFORM 800 is a computer-controlled system. Its software features real-time control of temperature, pressure monitoring, graphic display, automatic data storage, unlimited method storage, and complete record of instrument parameters.

Additional information

| Manufacturer | AURORA |

|---|---|

| Origin | Canada |

| Type | Automatic |