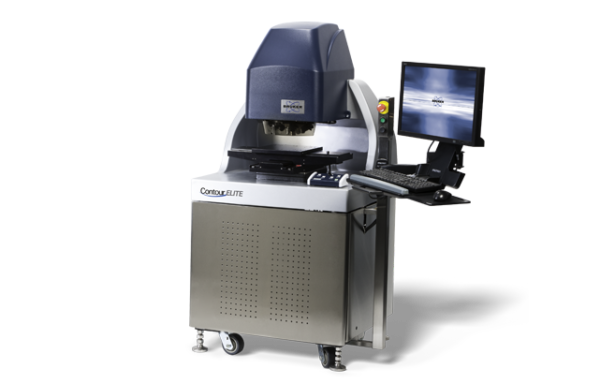

3D OPTICAL PROFILOMETER Contour Elite X

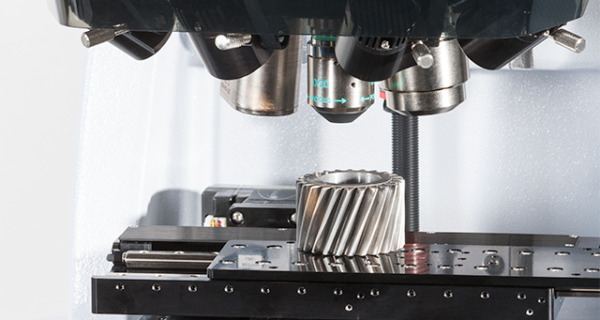

The fully automated, large-sample Contour Elite X 3D Optical Profiler combines unmatched measurement capabilities with highest vertical resolution over the industry’s largest field of view and high-fidelity color or monochrome imaging. No other metrology system provides the non-contact accuracy, throughput, operator convenience, and imaging capabilities to address such a vast range of production metrology applications. Designed from the ground up for the most demanding R&D, quality assurance, and process quality control needs, the Contour Elite X offers the ultimate gage-capable 3D optical profiling solution.

- Description

- Additional information

Description

HIGHLIGHTS

Reliable optical measurements

Inform quantifiable R&D and QA/QC decisions.

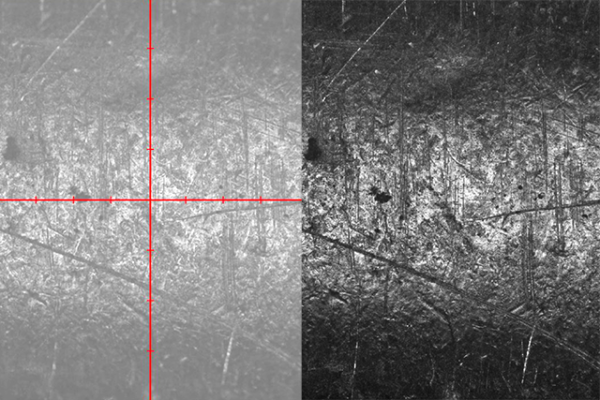

True-color imaging

Reveals previously hidden microscopic details.

Flexible staging and fixturing

Tailors metrology to your specific sample and application.

| – Max. Scan Range | >10 mm |

| – RMS Repeatability (PSI) | <0.03 nm; 0.02 nm typical |

| – Lateral Resolution: | 0.38 μm min (Sparrow criterion); 0.26 μm (with AcuityXR®) |

| – Step Height Accuracy: | <0.75% |

| – Step Height Repeatability | <0.1% 1 sigma repeatability |

| – Max. Scan: | 114 μm/sec (with standard camera) |

| – Sample Reflectivity: | 0.05% to 100% |

| – Max. Sample Slope | Up to 40° (shiny surfaces); Up to 87° (rough surfaces) |

| – Sample Height | Up to 100 mm (4 in.) |

| – Sample Weight | Up to 23 kg (50 lbs) |

| – XY Sample Stage | 300 mm (12 in.) automated; 0.5 μm encoders |

| – Z Focusing | 100 mm (4 in.) automated |

| – Tip/ Tilt Function | ±6° automated, computer-controlled tip/tilt head |

| – Objectives | Parfocal: 2.5X, 5X, 10X, 20X, 50X, 115X; LWD: 1X, 1.5X, 2X, 5X, 10X; TTM: 2X, 5X, 10X, 20X; Brightfield: 2.5X, 5X, 10X, 50X |

| – Available Zoom Lenses | 0.55X, 0.75X, 1X, 1.5X, 2X auto-sensing modules |

| – Camera | Standard-resolution monochrome: 640×480; High-resolution monochrome (option): 1376×1032; Standard-resolution color (option): 640×480; High-resolution color (option): 1376×1032 |

| – XY Automation: | Automated stitching, scatter, and grid automation |

| – Calibration | Via traceable step standards; Optional continuous self-calibration based on laser signal |

| – System Footprint | 852 mm (W) x 793 mm (D) x 1608 mm (H) |

| – Weight | 493 kg (1084 lbs) |

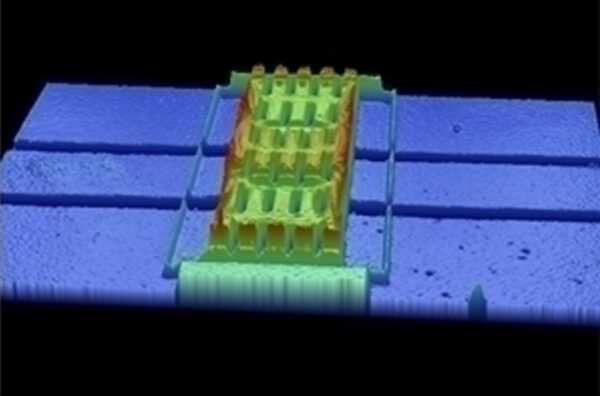

Color Imaging and Metrology Combined

The addition of high-fidelity color imaging, with exclusive side illumination and advanced algorithms, gives Contour Elite X users access to additional perspectives not possible on systems that provide metrology alone, as well as the capability to provide recognizable surface feature details for reporting. This enables users to segment data based on color or grayscale information to rapidly select areas of interest and collect critical metrology data from these specific regions. Combining high-end metrology with the ability to see, recognize, and display what was measured is of great importance, not only for understanding the data, but also for communicating the results.

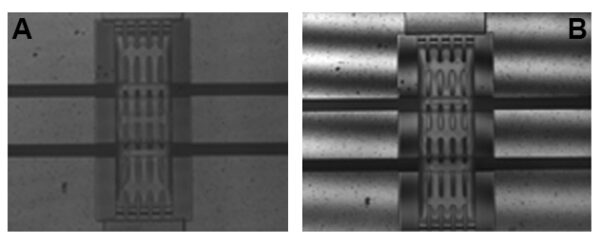

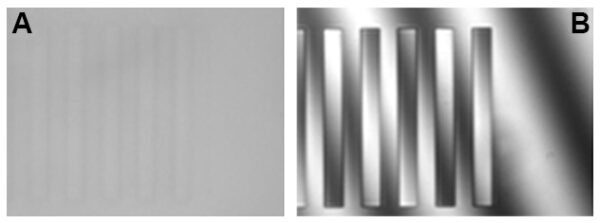

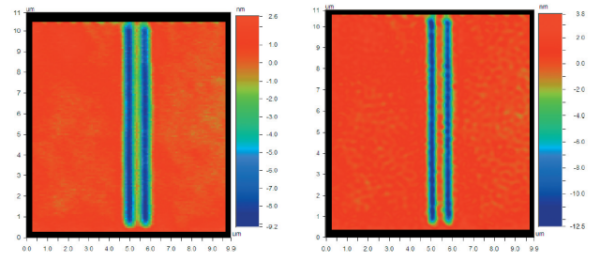

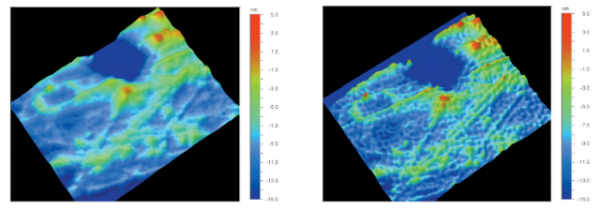

Best Lateral and Vertical Resolution

The Contour Elite X system boasts the best combined lateral and vertical resolution over the industry’s largest field of view, with a sub-nanometer to greater than 10 millimeters vertical range. It includes the R&D 100 Award-winning AcuityXR measurement technology, which provides the ability to break the diffraction limit in your optical measurements. In addition, the system can utilize a megapixel camera that increases X-Y spatial resolution. A large field of view and objective magnifications from 1X to 115X enable characterization of an extremely wide range of surface shapes and textures.

Rapid, Non-Destructive Imaging

The Contour Elite X profiler is a non-contact system with a large stage that leaves your samples or parts intact and undamaged. Our patented white light interferometry (WLI) technology acquires height data with sub-nanometer precision that is independent of the magnification used. This means that, even when sampling over a million data points in a millimeters-squared image area, a user is able to collect high-resolution height data—all within a few seconds.

Updating…..

Automotive and aerospace

Medical devices and implants

Semiconductors and microelectronics

Precision machining and tooling

AcuityXR

AcuityXR® combines unique, patent-pending Bruker hardware and software technology to enable select Contour 3D optical surface profilers to break the optical diffraction limit and deliver lateral resolutions previously considered unattainable with conventional optical microscopy techniques. It works on smooth surfaces where the phase of the reflected light is used to calculate surface height from the white-light-interferometric signal, improving sharpness, clarity, and definition of scratches, defects, and surface texture. Additionally, dimensional repeatability on nanoscale structures is improved by a factor of 5X.

|  |

Through Transmissive Media

“Enables high-resolution measurements through protective packaging, environmental chambers and other dispersive materials

– Measure samples through glass and other materials up to 3mm thick

– Innovative illumination enables up to 40x measurements

– Universal housing supports multiple magnifications and compensation materials

– 20x objective offers 25:1 aspect ratio for deep trench measurements

– For MEMS, materials science, biological applications, and more”

|

|

|

|

Upgrade Your Optical Profiler

Maximize your productivity with system hardware and software upgrades

– Hardware Upgrades

+ Computer Upgrade

The new Dell Precision computer with Windows 10 and the latest version of Vision64, version 5.70 enables new measurement capabilities, improved security, and enhanced remote support.

+ Automated FOV

The three position automated FOV allows quick swapping of FOV lenses from your computer.

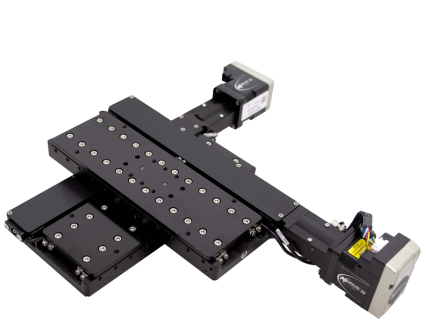

+ Motorized XY Stage

+ Motorized XY Stage

The 6-inch automated XY stage enables stitching and stage automation.

+ High-Resolution Cameras

Bruker offers a selection of color and monochrome cameras to meet your application needs.

+ Automated 5-Position Turret

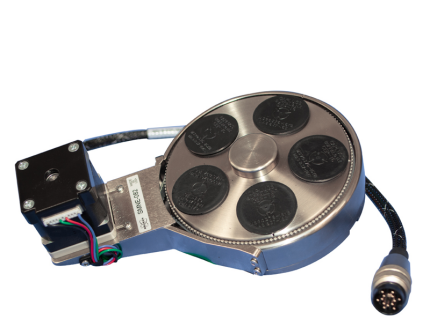

The automated five-position turret provides quick, efficient switching of objectives and adds objective parcentricity when used with a motorized XY stage. For use with all Bruker par-focal objectives.

+ Objectives and FOV Lenses

Increase capability of your optical profiler with Bruker objectives and FOV lenses. Bruker offers objectives with 1.5x to 115x magnifications.

– Software Upgrades

– Software Upgrades

+ AcuityXR Enhanced Resolution Measurement Mode

The AcuityXR measurement mode enhances the lateral resolution when using PSI (Phase Shifting Interferometry) or VXI measurement modes with the benefit of maintaining an equivalent field of view at higher resolution. It combines unique, patent-pending, hardware and software technology to enable select 3D Optical Surface Profilers to break the optical diffraction limit and deliver lateral resolutions that are traditionally unattainable with conventional interferometry techniques.

– Camera:

High-resolution monochrome (option): 1376×1032;

Standard-resolution color (option): 640×480;

High-resolution color (option): 1376×1032″

– Calibration:

Optional continuous self-calibration based on

laser signal

Vision64®

Bruker’s Vision64® Operation and Analysis Software provides the industry’s most functional and streamlined graphical user interface, combining intelligent architecture with intuitive visual workflow and extensive user-defined automation capabilities for fast and comprehensive data collection and analysis. An Advanced Production Interface allows adaptation of ContourGT-X to almost any production environment and automated process. The interface provides tools to customize process workflow, automate mapping, and load measurement recipes.

– Streamlined, customizable production interface

– Real-time automated measurement optimization

– Extensive library of filters and customizable analysis options

Additional information

| Manufacturer | Bruker-nano |

|---|---|

| Origin | Germany |

| Type | Automatic |