Economy muffle furnaces up to 1100 °C – LE 1/11

Muffle furnaces are the reliable and long-lasting all-rounders in the laboratory and are ideally suited for a large number of processes in the field of material research and heat treatment.

Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature.

Solid state relays provide for lownoise operation.

Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

Defined application within the constraints of the operating instructions.

Economy muffle furnaces up to 1100 °C.

- Description

- Additional information

Description

HIGHLIGHTS

Convincing price/performance ratio and the fast heat-up rates.

The dual shell furnace housing of rust-free stainless steel, their compact, lightweight constructions, or the heating elements encased in quartz glass tubes.

| Max. operating temperature | 1100 °C |

| Volume | 1 liter |

| Power | 1.6 kW |

| Temperature uniformity of +/− 5K in the empty workspace w x d x h | 40 x 65 x 60 |

| Heating time | 10 min |

| Inner dimensions in (mm) w x d x h | 90 x 115 x 110 |

| Outer dimensions in (mm) W x D x H | 290 x 280 x 410 |

| Weight | 15 Kg |

| Heating from two sides from heating elements protected in quartz glass tubes. | |

| Fast heating times. | |

| Maintenance-friendly replacement of heating elements and insulation. | |

| Flap door which can also be used as a work platform. | |

| Controller mounted under the door to save space. | |

| The dual shell furnace housing of rust-free stainless steel. | |

| CONTROLLER R7 | |

| + Digital PID-temperaturecontrol | |

| + Simple operation | |

| + Display of set and actual temperature | |

| + One free storeable temperature, which is dwelled until the controller is switch off |

| Supply power | 230 V, 1/N/PE, 50/60 Hz |

| Electrical | 1-phase |

| Temperature | +5°C up to +40°C |

| Humidity | < 80%, not precipitating |

| The furnace had been designed for preheating or ashing in air. |

| Only materials with known characteristics and melting temperatures may be used. |

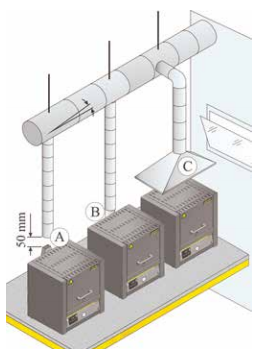

Exhaust Vent

Exhaust Air Extraction

Here the exhaust gas pipe NW 80 will be connected directly onto the furnace vent pipe

Ceramic ribbed plate

Dimensions (mm): 110 x 90 x 12.7

Stainless Steel Collecting Pan

Dimensions (mm): 85 x 100 x 20

Gloves ( For protection of the operator when loading For easy loading and unloading of the furnace or removing hot materials)

Tmax 650 °C and Tmax 700 °C

Charing Tongs (For easy loading and unloading of the furnace)

300 mm and 500 mm

Updating..

Updating…

Additional information

| Manufacturer | Nabertherm |

|---|---|

| Origin | Germany |

| Type | Manual |