HP8

SUSS MicroTec‘s manual hot plate HP8 has been developed specifically to meet the requirements of R&D work and small scale production. The 200mm hot plate (HP8) offers homogeneous temperature distribution as well as heating ramps with high repeating accuracy to ensure constant and stable process results.

- Description

- Additional information

Description

HIGHLIGHTS

Up to 200 mm substrates round or 6″ square

Homogeneous temperature distribution

Fast heating

High-performance protection coating of hot plate surface

Easy to use graphical touch screen interface

Programmable heating ramp (with dedicated touch panel controller

Perfectly matches the RCD8 or LabSpin tools

| Wafer Size | Up to 200mm round or 6″ square |

| User Interface | Dedicated touch panel controller |

| # of Recipes | max. 200 |

| # of Steps/Recipe | max. 40 |

| Step Time | 0 – 999s in 1s steps |

| Optional User Interface | Via controller of SUSS RCD8 tool |

| # of Recipes | >1000 |

| # of Steps/Recipe | max. 50 |

| Step Time | 0 – 999s in 1s steps |

| Outputs | Vacuum Nitrogen purge (optional) |

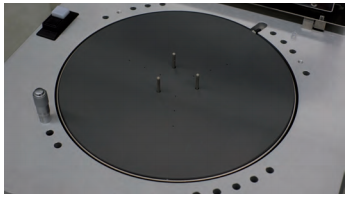

| Easy Handling | Via 3 lift pins |

| Temperature | Up to 250°C |

| Temperature Uniformity | +/-0.5°C up to120°C +/-1% for 120°C and above |

| Programmable Heating Ramp | 1°C/min up to 10°C/min (with dedicated touch panel controller |

| Options | Proximity setting > 0.1mm Nitrogen purge |

| Height x Width x Depth | HP8 BM (370mm x 390mm x 330mm) HP8 TT (370mm x 470mm x 420mm) HP8 T (600mm x 710mm x 1050mm) |

To aim for best in class temperature distribution SUSS HP8 doesn’t rely on conventional heating cartridges. Instead, several meters of heating coils are arranged within the base plate in a process proven pattern. This avoids hot or cool spots and ensures a uniform temperature distribution. The hot plate is specifically coated for increased mechanical and chemical resistance and easy cleaning.

The tool is offered in three different housings (bench mount, table top and stand alone) and can be conveniently controlled through a dedicated touch screen controller. If combined with the coat and develop platform RCD8, the HP8 can be optionally controlled using the same touch screen PC as the RCD8. The table top and bench mount version fits the SUSS MicroTec LabSpin series nicely as well in size and look & feel.

Not only the form factor and control possibilities offer high flexibility, but the variety of available options such as lift pins, proximity bake and nitrogen purge perfectly adapt to the daily lab needs.

The hot plate is equipped with lift pins as a standard, which permits convenient and safe substrate handling. The proximity option allows setting of the distance between substrate and hot plate surface by a micrometer, thus, giving a broad capability of processing options. The flow rate of the nitrogen purge option can be manually adjusted and is indicated by a digital display. Nitrogen purge and vacuum suction of the substrate can be individually selected for each step in the recipe editor. The closed double walled lid, ensures stable process conditions and prevents accidental touching of the hot surface by the operator.

The SUSS HP8 is available in three different versions: as a tabletop (TT) unit, for integration into a wet bench (BM) or as a stand

alone machine.”

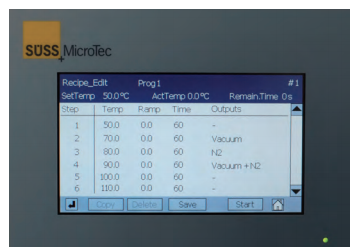

TOUCH SCREEN CONTROLLER

The dedicated touch screen controller allows convenient editing

of the recipes with the capability to choose time, temperature,

heating ramps and switched on vacuum or nitrogen purge individually for each step.

| Power Supply | |

| Power Voltage: | 220V, 50 Hz |

| Frequency: 50 – 60 Hz | 50 – 60 Hz |

| Vacuum: | – 0.8 bar |

| Nitrogen: | option |

Clean room: Class 1000

The HP8 hotplate has been developed for standard soft bake and hard bake processes in lithography and similar applications. The temperature range is designed as standard up to 250° C

three different versions

Bench Mount (BM)

Table Top (TT

Stand Alone (T)

Vacuum pump

Options Proximity setting > 0.1mm

Nitrogen purge”

Software is integrated

Additional information

| Manufacturer | Suss |

|---|---|

| Origin | Germany |

| Type | Manual |