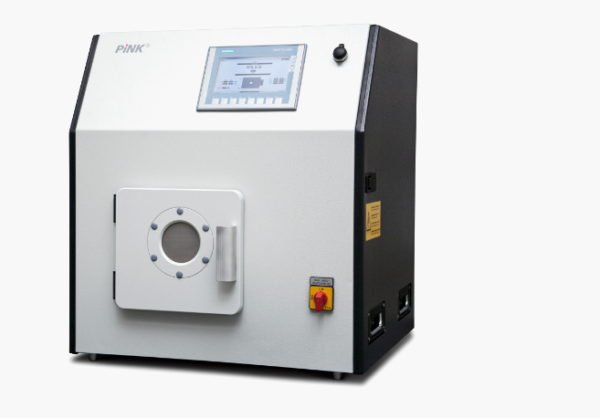

Low-pressure plasma system V6-G

– The standard system V6-G is designed as a tabletop unit for industrial small series production as well as for the low-pressure plasma treatment in R&D laboratories. It can be used for the surface treatment processes cleaning and activation.

– The integrated professional PLC control serves as a storage for definable processes and parameters.

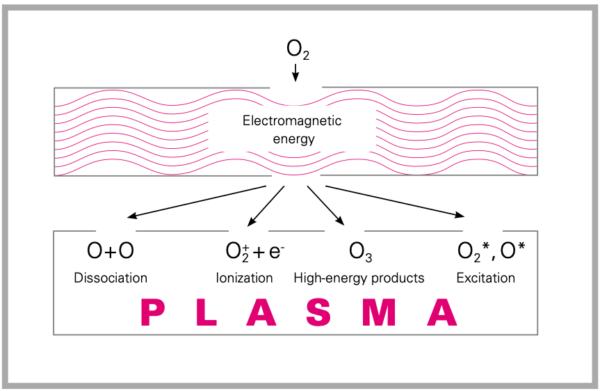

Low-pressure plasma: energy without heat

– At atmospheric pressure, plasma is hot – as in flames and arc discharges.

– If pressure is reduced to around 100 Pa (1 mbar), plasma can be formed and sustained even at room temperature. It is therefore also known as cold plasma or non-thermal plasma. However, the energy of the electrons corresponds to a temperature of several 1,000 K – forming a highly reactive medium.

– It enables both effective and gentle treatment of polymers and other temperature-sensitive materials.

– Low-pressure plasma cleaning results in surfaces free of organic contamina- tion. Treatment cycles of just a few minutes give outstanding results with no surface residues.

– The excellent crack penetration of low-pressure plasma is advantageous. This means that even intricately formed parts are perfectly cleaned since the gas also penetrates into small gaps that liquids cannot reach.

– The decisive factor in the plasma cleaning process is the formation of gaseous and hence volatile products that can be removed from the sample chamber without any problems. The plasma components react with the organic contamination and degrade it to water and carbon dioxide at room temperature:

(-CH2-CH2-)n + 3n O2 “” 2n CO2 + 2n H2O

- Description

- Additional information

Description

HIGHLIGHTS

High-quality systems

Easy operation due to a user- friendly touch screen panel with clear menu guidance.

Compact low-pressure tabletop device, suitable for both plasma applica- tions in batch production and R&D test series.

Stand-alone systems that can be equipped with different plasma producing frequencies and capacities. Therefore, they are usable for different plasma processes.

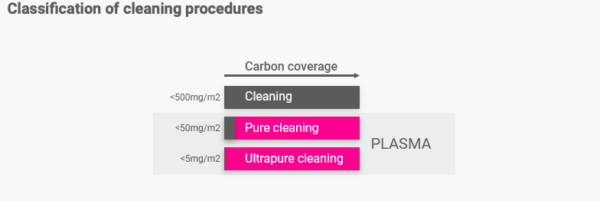

Advantages of plasma cleaning

• Extremely clean surfaces (ultrapure cleaning)

• Low treatment temperature

• High crack penetration

• No downstream drying necessary

• No detergent residues

• No waste disposal costs

• Low operating costs

• Eco-friendly process

| Process chamber |

| · Material Aluminium |

| · Inside dimensions:170 x 170 x 200 mm3 (W x H x D) |

| · Gas inlet – top or side mounted |

| · Microwave coupling – top or side mounted |

| · Vacuum coupling on chamber base or chamber side |

| · As standard the microwave- and gas inlet will be on chamber top and the vacuum connection on the base of the chamber |

| · Alternative the microwave- and gas inlet can be on the right side of the chamber and the vacuum connection will be on the left side of the chamber |

| · The position of gas- and microwave inlet as also the position of the vacuum connection has to be specified by order |

| Gas channel |

| · One gas channel with Mass Flow Controller and magnetic valve |

| · In front of each MFC an on/off solenoid valve is installed |

| · Flow rate and calibration gas as specified by customer |

| Process control |

| · PLC (Siemens S7) |

| · PC with 10.4″ touch panel (Windows 10, 250 GB hard disk, 800 x 600 pixel) |

| · Available are more than 100 programs with up to 50 program steps (number of programs is limited only by the memory capacity of the hard disk) |

| · Storage of all processes, analogue values and messages |

| · Electronic operating hours counter for all factors |

| · Intuitive operational concept, graphic display of the system status, display of messages, set and actual values as well as interactive chart functions. |

| · Language switching English / German |

| · Extensive and freely configurable user administration with automatic logout and password expiry in order to avoid unauthorized operation. Three user levels (operator, service, administration) are pre-configured. |

| · Integrated UPS |

| Interface (To the PC-Panel) |

| · Ethernet-Interface for uploading archive data or to connect to a network |

| · As an option, customer specific interfaces like SECS/GEM etc. and the storage of a predefined batch record as PDF is possible |

| USB-Connection |

| USB port to store archive data |

| VPN-Box |

| · VPN-Box for service or software updates |

| · At the site where the system is installed an internet connection is needed |

| Vacuum gauge |

| Pirani vacuum gauge |

| Plasma detector |

| · An integrated sensor is monitoring if Plasma is on or off. |

| Microwave power generator |

| · Frequency: 2.45 GHz |

| · Regulated magnetron |

| · Variable power max. 300 W |

| Safety equipment |

| · Main switch with emergency switch off function. (Emergency push button possible as an option) |

| · Mechanical interlock for microwave power |

| · Integrated vacuum interlock |

| · Microwave and UV absorbent viewing port |

| Compact low-pressure tabletop device, suitable for both plasma applica- tions in batch production and R&D test series. Stand-alone systems that can be equipped with different plasma producing frequencies and capacities. Therefore, they are usable for different plasma processes. |

| • Easy operation due to a user- friendly touch screen panel with clear menu guidance. |

Read more: Plasma Technology

| Power Supply |

| + 230 V, 50 / 60 Hz L/N/PE; AC 50/60 Hz; 230 V, +/- 5%. Other specifications on request. |

| Power input (without pump) |

| 0.5 kVA |

| Process gas connection (Ar, O2) |

| 6 mm O/D tube/hose (alternative: ¼” can be specified by the customer) |

| Input pressure max. 2 bar |

| Compressed air connection |

| 6 mm O/D tube/hose (alternative: ¼” can be specified by the customer) |

| Input pressure 6 – 8 bar |

| Vacuum connection |

| DN25 ISO-KF |

| Table |

| Chipcard production |

| A chipcard’s quality and service life depend essentially on the adhesion of the modules to the chipcard. If the adhesion is too weak, the module may detach itself from the chipcard, e.g. when strongly flexed, making the card unusable. To prevent this and to achieve optimal adhesion of the hotmelt bond, the modules are cleaned by plasma before bonding. |

| Leadframe treatment |

| For sufficient adhesion of the bond wires and chips to leadframes, the surface has to be as clean as possible. Adhesion is dramatically reduced by organic contamination and often prevents achievement of the desired adhesion quality. Because of the uneven contamination, leadframes have to be cleaned in their entirety. The process of low-pressure plasma cleaning is particularly suited to this, as fully loaded leadframe magazines can be cleaned without difficulty thanks to plasma’s high mobility. |

| Plasma cleaning of indicator bulbs |

| Indicator bulbs, which are still being used by automotive manufacturers, often have to be coated since the grooved diffusion glass of the indicators is colorless for both economic and optical reasons. The coating is applied in a dipping process. Durability of the coating depends on the adherence of the coating to the substrate. Even though contamination may only be as few as several µg/cm2, it reduces adherence considerably |

| Drill hole cleaning |

| Textured polymer films, like those used in ink jet printer cartridges, for example, are manufactured by applying a laser as a drilling and cutting tool. As an unwanted side effect, some of the incineration ash remains on the film around the textures. The primary aim of the plasma treatment is to remove this ash, which sticks more or less firmly to the surface. |

| Electrical engineering: quality capacitors |

| The capacitors covered by this report consist of a metallized (e.g. with aluminium or zinc) polymer film which is wound up and pressed into the final form. Then wires are fixed at the front by melting aluminium powder and the capacitor is sealed with a synthetic cap. Bond strength of the aluminium powder is reduced by contamination. It can be removed by a plasma process, eliminating the bonding problem. |

| Which materials are not really suitable for low-pressure plasma cleaning? – All materials causing a significant disturbance of the vacuum and / or plasma because of emission. This applies to some silicones and fabrics. – Plasma processes are hardly suitable for inorganic contaminations. However, workpieces with both inorganic and organic contaminations can be cleaned in combination with wet-chemical pre-cleaning. |

| Materials suitable for low-pressure plasma cleaning All vacuum-proof and plasma-resistant materials like e.g. most of the plastics, metals, glasses, ceramics, caoutchouc / rubber, even foam materials. |

| Vacuum pump I (Filled with oil) |

| · Double stage rotary vane pump |

| · Pumping speed is 9 m³/h |

| · Filled with fomblin oil. Ready for oxygen processes |

| · 1 m metal hose DN25 ISO-KF with centre rings and clamps for connecting the plasma system to the vacuum pump. |

| · Exhaust filter |

| Vacuum pump II (Dry pump) |

| · Dry pump with a vacuum speed of approx. 14m3/h |

| OERLIKON Leybold Vacuum pump Trivac D16BCS (oil sealed) |

| · Double stage rotary vane pump |

| · Operation with PFPE Oils. Ready for oxygen processes |

| · Offers an excellent ultimate pressure of 1×10-4 Torr and a pumping speed of 9.7 cfm |

| Ozone trap |

| · Placed after the vacuum pump, the ozone trap eliminates any ozone release from oxygen processes. |

| Metal hose |

| · 1 m metal hose NW 25 with centre rings and clamps for connecting the plasma system to the vacuum pump |

| Oxygen concentrator |

| · Instead a gas cylinder or gas tank an oxygen concentrator with a maximum gas flow of 5 l/min can be placed beside the system. |

| · Oxygen concentration between 87 and 86% |

| · Noise level: ≤ 40 dBA |

| · Outside dimensions: 580x380x240 mm (HxWxD) |

| · Weight: 15 kg |

| · Applicable till a height of 2.286 m over the sea level |

| · The electric power for the concentrator will be provided by the Plasma-system. |

| · On the back side of the system, a socket is integrated |

| Heating Plate |

| · To heat up substrates till 150°C |

| · Maximum dimensions of the substrate can be 4”-Wafer |

| · Electro heated. No active cooling is possible |

| · Including vacuum feedthrough and heat protection of the process chamber |

| Soft-start & Slow-vent |

| · These options allow for control of process chamber evacuation and vent speeds. Control of the velocities of evacuated air and vent gas prevents small parts, powders, etc. being carried away by turbulent gas flows causing damage, unwanted mixing, displacement, etc. |

| · The durations of soft-start and/or slow–vent can be independently preset. The soft-start and slow-vent conditions prevail for their respective set times, followed by the standard evacuation and vent conditions. |

| Chamber wall heating |

| · Heating mat for maximum 80°C |

| · No active cooling is possible |

| Gas channel |

| · Additional gas channel with mass flow controller and magnetic valve |

| Barcode laser scanner |

| · Corded barcode laser scanner incl. holder |

| · For reading different barcodes |

Intergrated

updating…

Additional information

| Manufacturer | PINK |

|---|---|

| Origin | Germany |

| Type | Semiautomatic |