Melt Flow Indexer MP 1200

The MP1200 is a superior, advanced, melt indexing system that is available in either manual or motorized configurations and features a new three zone band heater with three controllers that result in unparalleled temperature control of the furnace. When combined with the simple, menu driven, touch screen control you’ll agree that the MP1200 is in a league of its own.

The MP1200 Melt Flow Tester/Extrusion Plastometer. The MP1200 features the latest in melt flow measurement technology and allows operators to quickly and easily set up and perform melt flow tests: according to ASTM D1238, ISO 1133-1 & 2, and other international and industrial specifications.

The MP1200 is available in two distinct versions, a manual version (model MP1200), and a motorized version (model MP1200M). The manual MP1200 comes with everything you need (except weights and laboratory balance) to perform an ASTM D1238 Procedure A (manual cut) gravimetric melt flow rate (MFR). Test loads are applied manually.

The MP1200 can be upgraded with optional features, including ISO 1133 tools and an encoder-based programmable piston displacement transducer (or PPDT for short), for testing according to Procedures B & C (ASTM D1238) or for volume measurement tests (melt volume rate or MVR) and melt density calculations. Also available as options are Tinius Olsen’s manual and automatic specimen cutting tool attachments, which can be used with some materials to reduce the human involvement with the machine during the test and increase accuracy and repeatability of test results

- Description

- Additional information

Description

HIGHLIGHTS

Conforms to ISO 75, ISO 306, ASTM D648, and ASTM D1525

Fully automatic control of entire test cycle

Bath has port with an exhaust fan to remove interior oil fumes

Automatic correction for thermal expansion of test frames

Built-in heat exchanger on the 603 for rapid system cool down

Pneumatic station lift for easy specimen insertion and removal

Electronic transducers integrated into the loading rod assemblies for 0.001 mm resolution of deflection or penetration

Loading nose and rod assemblies provide 76 grams nominal load for ISO 75 ‘flatwise’ deflection temperature tests on 4 mm x 10 mm specimens at 0.45 Mpa stress

Accessories available include additional test stations, deflection temperature loading noses, Vicat loading noses and needles, weights, 64 mm span supports for ‘flatwise’ deflection temperature testing (the stations are predrilled to accept these supports)

Built-in specimen basket to catch any dislodged specimens

Air bearing-guided loading rods for virtually friction-free load application

| Specifications | Unit | 603 | 303 |

| Maximum number of stations | 6 | 3 | |

| Temperature range | ° C | 23-300 | |

| Temperature ramp | ° C | 50° or 120° per hou | |

| Temperature display resolution | ° C | 0.1 | |

| Temperature sensor | Platinum RTD located adjacent to the load application point at each station | ||

| Deflection/penetration measurement | LVDT | ||

| Deflection/penetration display resolution | mm | 0.001 | |

| Cooldown rate | Max. of 20o above cooling water temp. in 20 minutes | Max. of 20o above cooling water temp. in 30 minutes | |

| Temperature safety limit | Independent dual systems using thermostatic switch in bath and keypad selectable software limiting | ||

| 603 | 303 | |

| Dimensions (WxDxH) | 1067 x 762 x 572 mm | 813 x 635 x 585 mm |

| 42 x 30 x 22.5 in | 32 x 25 x 23 in | |

| Weight | 132 kg | 87 kg |

| 290 lb | 190 lb | |

| Heat transfer medium | 18 liters (4.8 US gallons) min | 11 liters (2.9 US gallons) |

| Water | Water supply for cooldown | |

| Clean air | Dry air filtered to 50 microns at 40psi (2.7 bar) min | |

| Power | 220 +/- 10%, 50/60Hz, 1 phase, 4.5kW | |

Updating…

Updating…

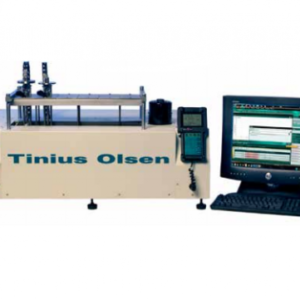

Horizon Software

Computer assisted data acquisition and machine control system which can be supplied with most Tinius Olsen testing equipment. The Horizon software package allows data to be collected, analyzed, graphed (where appropriate), and stored. If the testing machine allows, it can also provide control over testing operations.

Horizon has a comprehensive selection of pre-defined testing programs which includes powerful analysis of testing data, complex control, and sophisticated reporting. These programs can be modified and further enhanced to fit a customer’s particular requirements. The testing data collected by these programs may be exported to an outside source then later transferred to other data analysis systems. The Horizon databases may also be configured to be shared across several computers on a company’s network thereby allowing the testing programs and testing data to be utilized by multiple systems.

Using Horizon will make easy work of your materials testing, whether it’s designed for the demanding rigors of R&D or the charting and analysis functions of QC testing.

Key Features Overview

| Advanced Machine Segment Control |

| Customizable Report Layout |

| Data Archiving and Backup |

| Data Exporting (Results/Limits/Statistics/Points) |

| Data Importing (Result Entries/Limits) |

| Data Stored with SQL Server Express |

| Formula Generation |

| Library of Pre-Defined Testing Programs |

| Method/Output Editor |

| Multiple Graphs/Reports for Output |

| Multiple Machine Controlled by one Horizon |

| Multiple Users |

| Networking Databases |

| Report Consolidation |

| RS232 Device Communication |

| Security Lockout Capability |

| Touchscreen Capability |

| Video Extensometer Capability |

Test & Recall

The testing area allows for the viewing of live data from the machine while the test is being performed. Multiple tabs showcase the recalling of previous testing data as well as each testing machine connected to the software. Once a testing tab is created, it never has to be destroyed. When a new testing program needs to be run, simply change the Tab Options and load a new program. Each testing tab can be configured to display custom results, multiple graphs, multiple plots on a single graph, and live data (including custom formulas). Each tab may be customized to suite a user’s preferences.

Method/Output Editor

The testing program transferred from the Library may be customized for the customer in the Method and Output Editors. Create custom batch/sample identifiers for reporting and recalling purposes. Enhance the control of the machine with advanced machine segments. Automatically accept tests then print or email the report based on pre-defined limits. Customize multiple reports for various recipients. Import specimen data (such as dimensions or limits) from an outside file based on an identifier. Export results, limits, statistics, and/or curve points to an external file.

Custom Results

Methods transferred from the Library contain a number of results which have been standardized. In the Result Editor, however, custom result can be created. Such results can might be defined as entry type, a single point along a curve, a calculation between two points along a curve, a live source, or even a calculated formula. Depending upon how the result is created, it can be added to a testing panel to be viewed during the test or added to a report.

Library of Methods

A searchable database containing a variety of pre-defined testing routines. These methods are based on Standards from ASTM, ISO, EN, BS, DIN and many more. These routines include testing in tension, compression, flexure, torsion, melt index, heat distortion, hardness, impact, and more. Each method may be transferred into the user’s main database and customized with their own identifiers, units, report layouts, etc. With each new version update of Horizon, more and more routines are added to the Library.

Help Desk

Access to the tutorials which guide a user is various activities in the software.Displays details of the Software Key including items purchased. System Information displays valuable data regarding the software as well as the computer which it is installed upon. This guides the Tinius Olsen support staff when there are questions regarding system functionality. Please also note this page offers quick access to the Horizon QS program which will allow our Tinius Olsen support staff to take control of the computer when assistance is requested.

Additional information

| Manufacturer | Tinius Olsen |

|---|---|

| Origin | USA |