Rheoline ODR

The Oscillating Disc styled rheometer enjoyed renowned popularity in the early 60s and 70s. It is one of the most valued curemeters in the rubber industry to date, and still in continuous use. We understand that laboratories are reluctant to convert to the tried and proven specifications of a Moving Die Rheometer scenario, but need to gain the latest measurement technology.

Prescott Instruments have fashioned a perfect synergy of traditional principles and the latest modern technologies to build our Oscillating Disc Rheometer, more generally known as an ODR. Our design aims to revolutionise a classic and provide a seamless transition, when upgrading laboratory equipment.

Design conforms to ISO 3417 / ASTM D2084 Standards

- Description

- Additional information

Description

HIGHLIGHTS

The Prescott Rheoline ODR is equipped with high precision micro production die and rotor assembly. Using a microprocessor based PID control system; the temperatures of the dies are accurately maintained through the testing process. The test material sample is placed on the rotor and is secured in placed by pressure controlled platens.

The instrument is easy to maintain, and designed for ease of access. The oscillation amplitude can be mechanically adjusted with the options of 1.0 °, 3.0 ° and 5.0 °

| Die Configuration | Micro Production Die & Rotor, as specification (adjustable) |

| Oscillation Frequency | 1.67 Hz |

| Oscillation Amplitude | 1.0 °, 3.0 ° and 5.0 ° (One supplied as standard) |

| Temperature Range | Ambient to 250 °C |

| Temperature Control | 3 Term PID – Control Accuracy ± 0.03 °C |

| Units of Measurement | Torque lnlb, dNm. Temp. Celsius, Fahrenheit. Time Min/Sec, Min/Decimal. |

| Output Type | Real time display of: – Elastic Torque – Viscous Torque – Tangent Delta – Cure Rate |

| Real-Time Display | Standard torque curve Viscous curve Tan. Delta Cure Rate Programmable data points & limits Pass/Fail limits |

| Electrical | Single Phase 220/240V 50Hz / 110V 60Hz / 350VA |

| Pneumatics | Filtered Air, Min:0.41 Mpa / 60 psi / 4.14 Bar /4.2 kg/cm |

| – A rheometer is a laboratory device used to measure the way in which a liquid, suspension or slurry flows in response to applied forces |

| – It is used for those fluids which cannot be defined by a single value of viscosity and therefore require more parameters to be set and measured than is the case for a viscometer. |

| Rheoline VSC Volumetric Sample Cutter | Our Rheoline Volumetric Sample Cutter can be relied upon to provide consistent samples of volume and size to be inserted into the die cavity. | |

| This ergonomic designed pneumatic system enables precise user defined volume of uncured rubber and polymer material. The conveniently positioned and comfortable buttons are designed to work simultaneously to provide a safe working environment. | ||

| Technical Specification: | ||

| Sample Volume (adjustable): | 1 cm³ to 8 cm³ (normally 4.5 cm³) | |

| Nominal Sample Diameter: | 34 mm | |

| Nominal Sample Thickness @ 4.5 cm³: | 5.0 mm | |

| Repeatability: | 0.25% | |

| Delay between Squeeze and Cut (adjustable): | 1 sec to 10 sec | |

| Pneumatics: | Filtered Air, Min: 0.5 MPa | 72 psi | 5 Bar | 5.09 kg/cm² | |

| Weight: | 38 kg | |

| Dimensions: (W x D x H) | 300 mm x 300 mm x 800 mm | |

| Temperature Zones | Enables programmable temperature zones |

Software

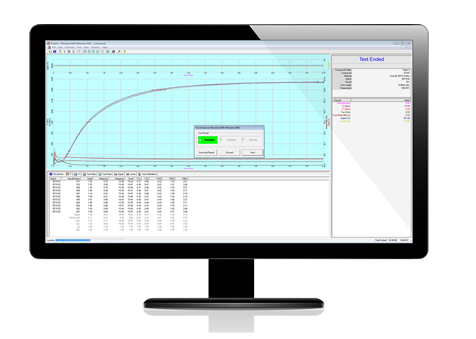

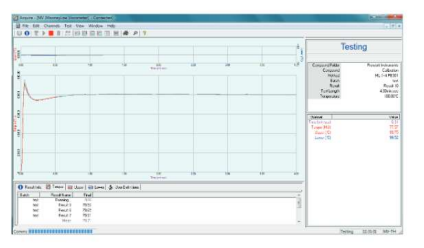

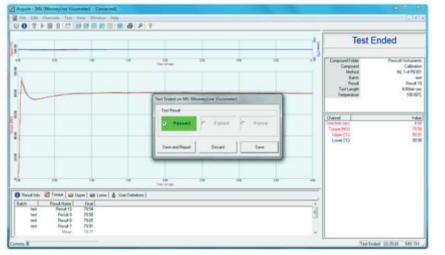

The Multi-Function Rheometer Lite is supplied with the latest computer hardware, pre-installed with our most innovative data acquisition and analysis Labline Lite software for Microsoft Windows ® OS.

The Lite version licenses a maximum of 10 ‘Test Specifications’ with any number of test points. The software is also complete with a calibration module.

Key Features

Automatic Pass/Fail Result

Laboratory Statistics

Multilingual

Simple Instrument & Test Configuration

Pre-loaded Test Specifications

Produce Trend charts

Easy Result Recalculation

Report Printing Capabilities

Supports ODBC Database Connections:

– Microsoft Access ®

– Microsoft SQL Server ®

– IBM DB2 ®

Test Methods

Standard Cure (MDR mode, non isothermal)

Strain (Sweep LAOS)

Payne test

Stress Relaxation

Frequency Sweep

Conditioning

Linked tests any combination of test method and any duration

Channels

Elastic Torque

Viscous Torque

Tangent Delta

Cure Rate

Temperature (Upper)

Temperature (Lower)

Pressure in Cavity (optional upgrade)

Complex Torque

Loss Angle

Storage Modulus

Loss Modulus

Complex Modulus

Storage Compliance

Loss Compliance

Complex Compliance

Real Dynamic Visc.

Imag. Dynamic Visc.

Dynamic Complex Visc.

Additional information

| Manufacturer | Prescott |

|---|---|

| Origin | USA |

| Type | Semiautomatic |