Torsion Testers

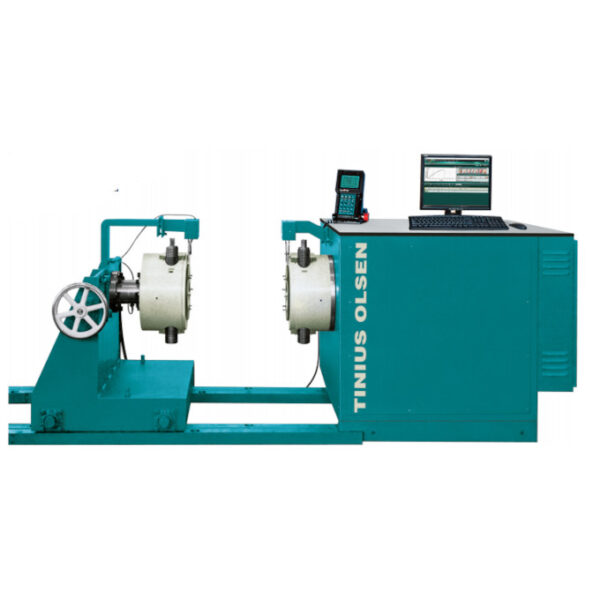

Torsion Testers or maximum versatility and capability, Tinius Olsen offers a full range of torsion testing machines in capacities from 10,000 to 300,000in.lbf or kg.cm (1,000 to 30,000N.m). Higher capacity and other longer length models are available upon request. These uniquely superior torsion testers provide loading and weighing capabilities in both directions of rotation. This feature makes it possible to conveniently determine not only the ultimate torque of a specimen, but also how that specimen behaves under conditions of continuous or intermittent torque loading in both directions….

The meter with max force = 10,000 lbf (100,000 Nm) has a fairly compact design, the whole machine is fastened on a long table according to the application standard with moving parts sliding on two guides.

- Description

- Additional information

Description

HIGHLIGHTS

These uniquely superior torsion testers provide loading and weighing capabilities in both directions of rotation

The rugged, electromechanical loading system employs a gear reduction system coupled directly to a variable speed drive motor.

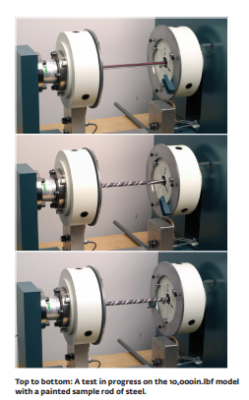

All torsion testers feature our patented bidirectional grips, which ensure slip-free specimen clamping regardless of the twist direction. With these precision machined universal grips, loads can be applied in both directions without changing grips

The reversible loading system provides positive, infinitely variable testing speeds from 5-180° per minute in either direction (the 10,000in.lbf model has a testing speed range from 5-360° per minute in either direction)

| Capacity | in.lbf or kgf.cm | 10,000 | 60,000 | 120,000 | 300,000 |

| N.m | 1000 | 6000 | 12000 | 30000 | |

| Mounting | Bench | Floor | Floor | Floor | |

| Maximum specimen diameter | in | 1.5 | 3 | 3 | 5 |

| mm | 38 | 76 | 76 | 127 | |

| Maximum specimen length | in | 18 | 72 | 60 | 90 |

| mm | 457 | 1829 | 1524 | 2286 | |

| Test speed | degrees per min | 5-360 | 5-180 | 5-180 | 5-180 |

| Torque measurement accuracy | +/- 0.5% of indicated torque from 0.2% to 100% capacity | ||||

| Position measurement accuracy | +/- 0.1% of reading or 0.05°, whichever is greater | ||||

| Speed accuracy | +/- 0.1% of set speed | ||||

| The basic structure of each torsion meter has a main force supply system and a digital controller and force designation system mounted on a fixed part of the machine. Load determination unit with “torque moment” sensor mounted on the movable device in a sliding manner on two parallel rails allowing easy length adjustment when mounting the specimen. | |||||

| The 4-axis slideway glides in the two grooves of two parallel guides allowing for quick test piece positioning, in addition it features compensation for changes in the length of the test piece during application. . The standard length distance for the two mounts is 7 feet (equivalent to 2.1m), but the machine can also meet a variety of distances depending on the purpose of use. | |||||

| With the structure of the holder rotates in opposite directions to ensure that the specimen is held firmly without deviation and the holder is always balanced while twisting, so it is applicable in both directions (the specimen will twist from left to right). and vice versa from right to left) with high accuracy without the need to change the mount. The sample mounting operation is quite easy and simple thanks to the special structure of the torsion mount. | |||||

| Capacity | in.lbf or kgf.cm | 10,000 | 60,000 | 120,000 | 300,000 |

| N.m | 1000 | 6000 | 12000 | 30000 | |

| Operating temperature range | 32-100°F (0-38°C) | ||||

| Storage temperature rang | 14-115°F (-10-45°C) | ||||

| Humidity range | 10% to 90% non-condensing, wet bulb method | ||||

| Power | Standard optional voltages 220/240VAC, 50-60Hz; power must be free of spikes and surges exceeding 10% of the nominal voltage | ||||

| Weight (net) | lb | 1100 | 6200 | 7625 | 13500 |

| kg | 500 | 2800 | 3500 | 6130 | |

| Dimensions (LxDxH) | in | 62 x 25 x 29 | 148 x 36 x 78 | 176 x 45 x 78 | 220 x 64 x 84 |

| mm | 1570 x 630 x 730 | 3760 x 900 x 1980 | 4470 x 1140 x 1980 | 5590 x 1620 x 2130 | |

The Tinius Olsen Torque Gauge can be applied to a wide variety of materials and products such as steel, alloys, metals, machine parts, synthetic resins, etc., and can measure different force strengths. together. Customers can choose their products through the available measurement ranges, from 10,000lbf (kg.cm) to 300,000lbf (kg.cm) equivalent from 100,000Nm to 3,000,000Nm. In addition, the company can also manufacture according to the needs of customers.

Outstanding manufacturing technology with the ability to both measure the torsion force and measure the product’s load in both torsional directions. With this feature, it is more convenient for the user to determine not only the product’s torque, but also the product’s ability to withstand under conditions of continuous and intermittent force. period in both helix directions.

| Set of holding chucks | These jaws enable the testing of specimens from 5/16″ to at least 1-1/2″ in diameter. |

| 220V Transformer | 220V, 50/60Hz, single phase |

| Torsion 2-Way Chucks 200K in-lbf w/Vee Wedges | Pair of two (2) Torsion Chucks with wedge grips suitable for gripping specimens to 127mm diameter. |

| Model 602 Angle of Twist Module |

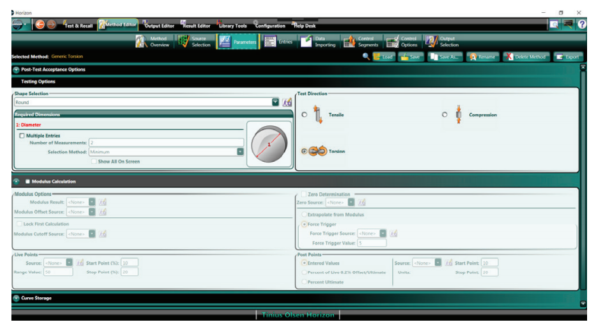

| Horizon Sofware | |

| The software is built on a foundation of long-term use that provides a complete and diverse range of problems for experimental manipulation as well as data processing. The company also offers many blocks of product data, allowing to design a measurement process according to standards or according to user needs very clearly and effectively with pre-set material/product parameters. such as: metals, paper, composite materials, synthetic resins, rubber, textile products, fabrics, etc. From the basic features of the software, users can further expand the applications according to their own needs and be fully active in their work. | |

Advanced and modern working style. Advanced and modern working style. | |

| Ability to report comprehensively and meticulously. | |

| Standard program SPC works and displays graphically. | |

Find programs that save graphs, statistics, one or more programs at the same time. | |

| Application data is saved to expand for other programs. | |

| Expand the ability to learn and create standards for users. | |

User-specific configuration format and control installation operations. | |

| The interface is clear, easy to see, easy to understand, easy to control. |

Additional information

| Manufacturer | Tinius Olsen |

|---|---|

| Origin | UK |

| Type | Semiautomatic |