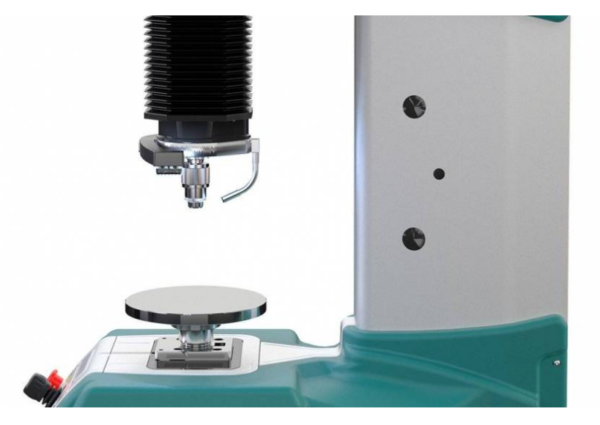

Hardness tester FH 11 Rockwell

The FH11 Series represents one of Tinius Olsen’s most advanced system for universal hardness testing. This multi purpose hardness testing instrument uses a modern design and innovative technology, based on the application of mechatronic components and high-resolution video machine vision systems.

The high level of precision combined with high definition imaging means that the scope of applications for the FH11 is almost unlimited; whether those applications cover aircraft engine parts, automobile parts, production lines, general quality assurance or general laboratory use.

The FH 11 is available in three models with force ranges consisting of 1 to 250 kgf, 3 to 750 kgf, 10 to 3000 kgf. A special feature of the FH 11 is the six position motorized turret, which comes as a standard on each system. The turret can hold up to 3 different indentors and/or 3 (or 4 if only 2 indenters are selected) objectives. Combine the turret with an optional X-Y stage, a rotary table or inclination table and you have one of the most comprehensive testing instruments available.

- Description

- Additional information

Description

HIGHLIGHTS

Large range of optional accessories.

Fixed workpiece position (no spindle).

Descending test head with automatic workpiece detection.

Rockwell, Superficial Rockwell, Vickers, Knoop, Brinell, Ball indentation, HVT and HBT scales.

Free definable, manual or motorized six-position turret for objectives and indenters at choice.

High definition optical system for images of 0.7-1000x magnification.

Horizon hardness testing firmware and database file system.

Large, adjustable 15in (381mm) industrial touchscreen.

LAN, WLAN, USB-2, RS232, printer and DVI connectivity – standard

Built-in hard drive offers nearly endless file storing – standard.

Free definable test patterns case depth, traverse, free style, etc – optional

Machine covers made of shock, damage and fireresistant and recyclable materials.

Automatic or manual focus, manual or fully automatic indent measurement – standard.

Large testpiece accommodation H=300mm (11.8in) x D=220mm (8.7in)

Superior range of test loads/force application ranging from 1kgf (2.2lbf) to 3000kgf (6614lbf) over three models.

| Scales/test loads/force | 1kgf/9.8N/2.2lbf to 250kgf/2.45kN/ 551lbf; 3kgf/29N/6.6lbf to 750kgf/ 7.35kN/1654lbf; 10kgf/98N/22lbf to 3000kgf/29kN/6614lbf |

| Rockwell, A- H, K-M, P, R,V | All scales (depending on model) |

| Superficial Rockwell, N, T, X, Y | All scales (depending on model) |

| Vickers HV | 1kgf/9.8N to 120kgf/1176N (2.2-265lbf) (depending on model) |

| Knoop | 1, 2kg (depending on model) |

| HVT | 50kgf/490N, 100kgf/980.7N (110lbf, 220lbf) |

| Brinell | 1kgf/9.8N/2.2lbf to 3000kgf/29kN/ 6614lbf (depending on model |

| HBT | 5/250 (depending on model) |

| Force application system | |

| Linear force actuator | Standard |

| Load cell, closed loop, force feedback system | Standard |

| Motorized heavy duty turret with six positions | Standard |

| Indenter positions | 3 |

| Objective positions | 3 |

| LED optical indent workpiece illumination | Standard |

| Optical measuring system | |

| 5 megapixel high definition optical system | Standard |

| Auto focus | Standard |

| Manual focus | Standard |

| Fully automatic indent measuring | Standard |

| Manual on-screen indent measuring | Standard |

| Magnification ratio | 0.7-1000x |

| Depth measurement system | |

| Heidenhain high resolution optical systems | Standard |

| Hardware and user interface | |

| Adjustable 15in full color industrial touchscreen | Standard |

| MS Windows 7 Ultimate license | Standard |

| Horizon FH-11 hardness testing firmware | Standard |

| Automatic image and file storage | Standard |

| Stores files images | Standard |

| Forms FH-11 set of customized reports | Standard |

| Universal motorized X-Y stage controls | Standard |

| Connectivity | |

| External digital (DVI) TFT screen output | Standard |

| External keyboard and mouse connections | Standard |

| LAN (local area network connection) | Standard |

| WLAN (wireless network connection) | Standard |

| Bi-directional RS232 | Standard |

| Printer/USB-2 output | Standard |

| Built-in motorized X-Y stage driver | Standard |

| Hardness resolution | 0.01 Rockwell, 0.1 Vickers, 1 Brinell |

| Objectives | Three installed for 0.7-1000x |

| Workpiece accommodation | Vertical capacity 300mm |

| Horizontal capacity | 220mm/8.7in (from center-line) |

| Force tolerance Max. | < 1% |

| Force control | 1-99 seconds |

| Light source | White power LED |

| Weight | 242kg (181lb) |

| Power | 100V AC to 240V AC, 50Hz/60Hz, single phase |

Hardness testers available that can rapidly and accurately determine the hardness value of a wide variety of materials including metals, plastics, large parts, small precision parts

Hardness testers are widely used in many fields such as: manufacturing, quality control and engineering services.

Standard Accessories

● V-anvil

● Flat anvil 60mm

● Round testing table 150mm

● Brinell microscope (FH-30-1)

● Power cable

● Four adjustable feet

● Certificate

● Installation and user manual

● Wireless mouse & keyboard

Options Accessories

● Certified indenters

● Rockwell C indenter

● Rockwell B indenter

● Brinell ball indenters 1mm, 2.5mm, 5mm, 10mm (FH-30-1)

● Certified reference hardness blocks

● Custom testing tables

● Precision vise for small parts, jaw width 36mm

● Precision vise for small parts, jaw width 42mm

● Precision vise for small parts, jaw width 75mm

● V-blocks and special clamps

● Solid tester table and storage cabinet

● Firmware service over internet ‘Team Viewer”

Horizon Software

Computer assisted data acquisition and machine control system which can be supplied with most Tinius Olsen testing equipment. The Horizon software package allows data to be collected, analyzed, graphed (where appropriate), and stored. If the testing machine allows, it can also provide control over testing operations.

Horizon has a comprehensive selection of pre-defined testing programs which includes powerful analysis of testing data, complex control, and sophisticated reporting. These programs can be modified and further enhanced to fit a customer’s particular requirements. The testing data collected by these programs may be exported to an outside source then later transferred to other data analysis systems. The Horizon databases may also be configured to be shared across several computers on a company’s network thereby allowing the testing programs and testing data to be utilized by multiple systems.

Using Horizon will make easy work of your materials testing, whether it’s designed for the demanding rigors of R&D or the charting and analysis functions of QC testing.

Key Features Overview

| Advanced Machine Segment Control |

| Customizable Report Layout |

| Data Archiving and Backup |

| Data Exporting (Results/Limits/Statistics/Points) |

| Data Importing (Result Entries/Limits) |

| Data Stored with SQL Server Express |

| Formula Generation |

| Library of Pre-Defined Testing Programs |

| Method/Output Editor |

| Multiple Graphs/Reports for Output |

| Multiple Machine Controlled by one Horizon |

| Multiple Users |

| Networking Databases |

| Report Consolidation |

| RS232 Device Communication |

| Security Lockout Capability |

| Touchscreen Capability |

| Video Extensometer Capability |

Test & Recall

The testing area allows for the viewing of live data from the machine while the test is being performed. Multiple tabs showcase the recalling of previous testing data as well as each testing machine connected to the software. Once a testing tab is created, it never has to be destroyed. When a new testing program needs to be run, simply change the Tab Options and load a new program. Each testing tab can be configured to display custom results, multiple graphs, multiple plots on a single graph, and live data (including custom formulas). Each tab may be customized to suite a user’s preferences.

Method/Output Editor

The testing program transferred from the Library may be customized for the customer in the Method and Output Editors. Create custom batch/sample identifiers for reporting and recalling purposes. Enhance the control of the machine with advanced machine segments. Automatically accept tests then print or email the report based on pre-defined limits. Customize multiple reports for various recipients. Import specimen data (such as dimensions or limits) from an outside file based on an identifier. Export results, limits, statistics, and/or curve points to an external file.

Custom Results

Methods transferred from the Library contain a number of results which have been standardized. In the Result Editor, however, custom result can be created. Such results can might be defined as entry type, a single point along a curve, a calculation between two points along a curve, a live source, or even a calculated formula. Depending upon how the result is created, it can be added to a testing panel to be viewed during the test or added to a report.

Library of Methods

A searchable database containing a variety of pre-defined testing routines. These methods are based on Standards from ASTM, ISO, EN, BS, DIN and many more. These routines include testing in tension, compression, flexure, torsion, melt index, heat distortion, hardness, impact, and more. Each method may be transferred into the user’s main database and customized with their own identifiers, units, report layouts, etc. With each new version update of Horizon, more and more routines are added to the Library.

Help Desk

Access to the tutorials which guide a user is various activities in the software.Displays details of the Software Key including items purchased. System Information displays valuable data regarding the software as well as the computer which it is installed upon. This guides the Tinius Olsen support staff when there are questions regarding system functionality. Please also note this page offers quick access to the Horizon QS program which will allow our Tinius Olsen support staff to take control of the computer when assistance is requested.

Additional information

| Manufacturer | Tinius Olsen |

|---|---|

| Origin | USA |

| Type | Manual |