MACHINE FOR DYNAMIC FATIGUE TESTS – PFO 20

Detections are made using accurate position transducers for acceleration and load.

The operation frequency rangesof this kind of machines are essentially two: 4-25/40 Hz, with +/- 0.05/2.5 mm excitation amplitude and 25-500 Hz, with +/- 0.025/0.2 mm excitation amplitude. For special requirements, such as checking a motor support in resonance conditions, an inertial mass with variable weights can be installed on the machine.

Even for long time tests, our machines maintain a high-idelity waveform while running at a high frequency. According to the customers’ needs, we can provide testing machines with static load from 5 to 1000 kN with standard waveforms (sine, ramp, square) or programmable ones.

- Description

- Additional information

Description

HIGHLIGHTS

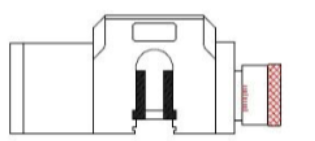

Consisting of a base in which the 200 kN actuator and the two columns that guide the mobile crosspiece are placed.

The mobile crosspiece can be moved with two hydraulic cylinders located on the sides of the base and lockable, in the chosen position, with 6 or more screws of suitable size or with locking bushes.

| Distance between the columns | 500 mm | |

| Maximum space in height excluding jaws | 750 mm | |

| Maximum space between the jaws | ≈ 400 mm | |

| Mobile crosshead travel | 400 mm | |

| +/- 20 kN ACTUATOR | Max static force | ± 29 kN |

| Max dynamic force | ± 20 kN | |

| Stroke max | ± 50 mm (100 mm totale) | |

| Maximum stroke with sine wave at 50Hz | ± 0.5 mm (1 mm totale) | |

| Maximum frequency | 50 Hz | |

| MOOG high response servovalve | n. 1 | |

| Operating pressure | 220 bar | |

| HYDRAULIC PLANT | Tank (capacity) | 400 L |

| Helical gear pump | n.1 x 11,4 cc (16.5 L/min) | |

| Engines | n.1 x 7.5 Kw | |

| Delivery accumulator | n.1 x 1 L (preload 180 bar) | |

| Working pressure | 220 bar | |

Servo-controlled actuato

Servo-controlled actuator with counter-reaction ring in displacement or load, the type of counter-reaction must be selected at the start of the test

The actuator has a simple hydrostatic support, equipped with a high response MOOG servo valve, an anti-torque unit, a transducer for stroke control (LVDT), and a filter on the pressure line with electric clogging detection

Hydraulic Plant

– Suction filter

– Oil level sensor

– Temperature transducer

– Pressure transducer

– 2-set maximum pressure valve (high / low pressure)

– Solenoid valve for high / low flow rate selection

– Water / oil exchanger designed to guarantee continuous operation

– Flexible pipes (P and T), for hydraulic connection with machinery for a maximum length of 3000 mm, pressure pipes equipped with safety ropes

– Valve group for the movement of the crosspiece

– Valve group for locking and unlocking the jaws.

| Power supply | 230 V ac 50 Hz |

| Dimensions(W x D x H) | 950mm x 550mm x 2000mm |

These tests are used either to generate fatigue life and crack growth data, identify critical locations or demonstrate the safety of a structure that may be susceptible to fatigue

Demonstrate the safety of a structure that may be susceptible to widespread fatigue damage.

Generate fatigue data

Validate expectations for crack initiation and growth pattern.

Fatigue tests can also be used to determine the extent that widespread fatigue damage may be a problem.

ELECTRONIC CABINET

Electronic cabinet consisting of a rack-door cabinet in which a Personal computer and the servo-control rack module are housed.

Industrial PC (Intel Core I3 processor, OS Windows 10 Pro), LCD 19 “monitor, keyboard, and mouse. The PC is equipped with a National Instruments acquisition card for PC, command, and digital inputs/outputs

Electronic servo-control module – 19 ”rack amplifiers including

a power supply slot 230 V ac 50 Hz an independent PID circuit slot with a double feedback loop with proportional, integrative, and derivative action: one for the piston stroke and one for the load signal amplification slots a power supply cable, servo-control-servo valve connection cables, travel and load signal inputs.

In the event of instant failure of the 230 V supply voltage ac of electronic equipment, can occur undesired movements of the piston such as to damage the particular in the test. In order to avoid these effects and to ensure the safety of the operator, when assembling the part being tested, it is necessary to power the electronic modules and the control PC with a power supply served by an uninterruptible power supply (consumption approximately 700 VA). The industrial UPS group is included in the supply

The static load will be limited to 25kN software.

Electrical system

Wardrobe

Main door lock switch

Emergency module and related management contactors

Motor protection, fuses or protection switches for Motor, power supply and PC

power supply

contactors and Relays for engine and valve management

Siemens S7 1200 PLC for high / low pressure, high / low flow, up / down management crossbar, alarm management, heat exchanger and dialogue with the PC

Control panel on board composed machine 1 emergency push-button, 1 motor start button engine stop button, 1 cycle start button, 1 stop button cycle, 1 crossbar up / down selector and 2 selettori di bloccaggio/sbloccaggio delle ganasce

SAFETY DEVICES

Fixed protections in aluminum and LEXAN profiles on the rear front and on the two sides

Mobile protection in aluminum profiles and LEXAN on the front front. the Mobile protection is monitored by safety limit switches or hinged safety switches

Equipment provided:

2 jaws with hydraulic closing system on one side and manual adjustment of the mechanical locking axis on the other side.

The maximum opening of the jaws is 40mm.

Each jaw is equipped with 2 clamp holders and 2 round clamps from ø5mm to ø10 mm.

Updating…

Additional information

| Manufacturer | Echolab |

|---|---|

| Origin | Italy |

| Type | Manual |