Dynamic Mechanical Analyser

Versatile. Powerful. Accurate. Test with confidence.

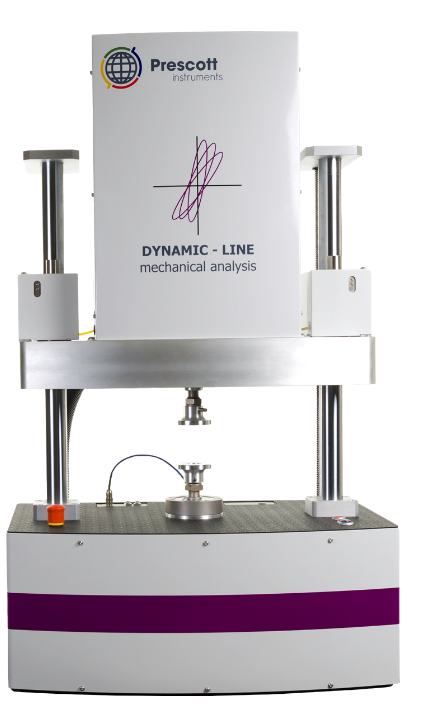

Prescott Instruments’ Dynamic Mechanical Analyser is a versatile and high precision DMA designed for dynamic and static testing on a variety of materials with a full range of force. From an established global manufacturer in specialist laboratory equipment, this DMA has a unique and rigid design that is easy to operate and maintain, ensuring a reliable and safe testing operation for the user.

Using state-of-the-art linear motor technology, this DMA can efficiently produce over 3 kN of static force and 5 kN of dynamic force at a frequency of up to 100 Hz. With complete user flexibility, the DMA allows you to test a range of materials, components and systems, fixed in place by versatile high-performance clamping fixtures. Capable of performing a range of test methods in different deformation modes, the DMA delivers force control to the most precise accuracies available.

Our innovative and easy to use new Labline software enables the user to set up tests easily with minimal training required, giving test confidence and maximum productivity throughout. Labline software can be relied upon for precise results and a consistent testing process, with a wide range of test modes available.

- Description

- Additional information

Description

HIGHLIGHTS

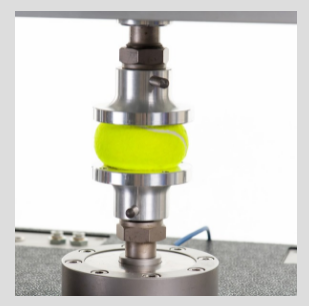

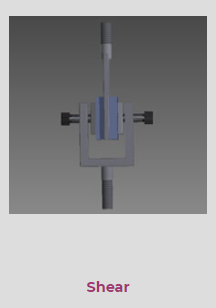

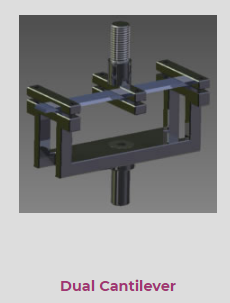

A range of high performance clamping fixtures are available that enable testing in more than one mode of deformation. Samples of various dimensions and natures can be accommodated, including but not limited to rubber, polymers, elastomers and composites.

Service Flexibility

This instrument has been designed keeping our customers testing needs in mind. With minimal maintenance required for the DMA, operator productivity levels are maximised. Should a service and calibration be necessary, the integrated high quality parts are easy to access and remove, making it a simple and convenient process.

This instrument can be relied upon for a simple and safe operation and has an emergency stop feature integrated into the design to protect users, whilst conforming to international safety standards.

Low Noise

Operation When in use, this Dynamic Mechanical Analysis will produce minimal mechanical noise enabling a productive test environment for the operators.

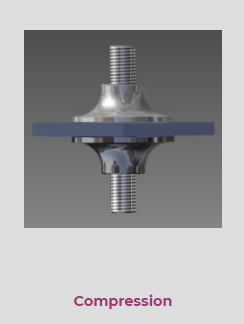

Various tests such as: Compression, Tension, Shear, 3 Point Bending, Single Cantilever, Dual Cantilever

| Maximum Static Force | 3.4 kN |

| Maximum Dynamic Force | 5 kN |

| Frequency Range | 0.001 Hz to 100 Hz |

| Maximum Stroke Length | 50.8 mm (customisable) |

| Displacement Resolution | 0.001 mm |

| Test space size (W x D x H) | 500 x 550 x 300 mm (customisable) |

Key Features

Powerful linear technology

High dynamic performance, capable of over 100 Hz

Broad range of deformation modes and test methods

Compatible with the new Labline software

Configurable for numerous materials

Optional temperature-controlled environment test cabinet

Flexibility to use a range of clamps for testing

Long term durability supporting a high volume of tests

Emergency stop button safety feature

Designed for ease of access

Customisable test space dimensions

Simple installation

Virtually maintenance free

Stand-alone unit

Test Modes

| Static Stress/Strain In this mode, stress or strain can either be constant or applied at a uniform rate. Results include Young’s Modulus, Hookean stiffness, elastic limit, material strength and distortion at break. |

| Dynamic Stress/Strain At constant frequency, material response is monitored as stress amplitude increases. For each cycle, the complex stiffness, complex modulus and complex viscosity can be calculated. Can also be used to identify the Linear Viscoelastic Range. |

| Transient Testing For creep testing, stress is held constant and deformation is measured over time. For stress relaxation, the stress required to hold a constant deformation is measured over time. This mode is used to measure the long-term effects of loading and the ability to return to original shape. |

| Time-Temperature Scans With the optional temperature control unit, material response as a function of temperature can be measured. Thermal transitions, rate of cure and operating ranges can all be determined. Samples can also undergo accelerated ageing during testing. |

Linear Encoder

A high performance Linear Encoder is supplied as part of the Linear Servo Motor, providing precise and reliable position feedback and communication data.

Environment Cabinet

An optional temperature test chamber can be incorporated to give control, stability and flexibility of temperature during testing.

| Electrical | Three Phase 15 Amp |

| Dimensions(W x D x H) | 800 mm x 550 mm x 1500 mm |

| Weight | 320 kg |

| Non-Linear Material Properties The application of oscillatory forces enables material effects to be characterised beyond the linear regime. Stiffness, elastic modulus and viscosity can all be expressed as complex quantities that incorporate non-linear behaviours. The reaction of the sample as a function of both amplitude and frequency can be used to build a model of material properties that include both physical and chemical characteristics. |

| Failure & Fatigue Testing The expected lifetime of a material or finished component can be deduced using either static or dynamic forces that mimic realistic stresses. The effect of constant stress, strain or strain rate can be used to determine strength, toughness and evaluate modes of failure. With dynamic forces, the repetitive loading of a material can be used to calculate fatigue strength, fatigue life and the dependency on the form, amplitude and frequency of oscillation. |

| Non-Destructive Testing The properties of a material, component or system can also be analysed without causing any damage. In this way, discontinuities can be highlighted during inspection without impacting on the future usability of the sample. |

Compression Accessories

Tension Accessories

Shear Accessories

3 Point Bending Accessories

Single Cantilever Accessories

Dual Cantilever Accessories

Labline Software

Featuring state-of-the art architecture, the new Labline software comprises of an easy to use interface ensuring our clients have a user friendly process to increase their production levels and assist in better decision making. Our Labline software enables the user to set up tests with simple and easy steps resulting in minimal training required, providing test confidence and productivity throughout. Labline software can be relied upon for precise results and has a high level of flexibility with a wide range of test conditions available.

| Acquire | View previous test information from the last test that was performed Quick decision making with our Pass/Fail colour indicators Flexibility to change channel trace colours Trend chart alarm indicating quality drift Load previous test results while running a test Add note option to test results Optional screensaver to provide a clear indication when an instrument is ready for testing |

| Database | Get full confidence in your designs with a wide range of test method templates All test method details visible in the tab Default test points available for each test method type Test points can define both Process Limits and Control Limits Flexible tabs allowing several test methods to be viewed or edited A clear indication of the test type |

| Viewer | The use of tabs allows several sets of results to be viewed |

Additional information

| Manufacturer | Prescott |

|---|---|

| Origin | UK |

| Type | Semiautomatic |