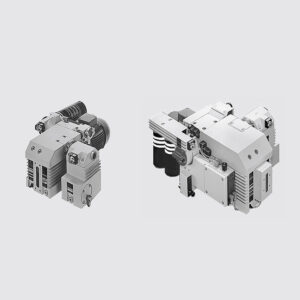

Trivac D 25BCS

TRIVAC B, Two-Stage Rotary Vane

The TRIVAC BCS –Production of semiconductors and

in the area of chemistry

- Description

- Additional information

Description

HIGHLIGHTS

The TRIVAC BCS pumps are oil sealed vacuum pumps operating according to the rotary vane principle . Oil which is injected into the pump chamber is used for sealing, lubrication and cool- ing purposes

The pump body is assembled from individual parts without sealing compo- nents . The parts are pinned in order to ensure easy disassembly and reassem- bly of the parts

The motor is connected to the pumping section via an elastic coupling

In addition, the TRIVAC BCS is ready for system integration (adaptable to dif- ferent applications)

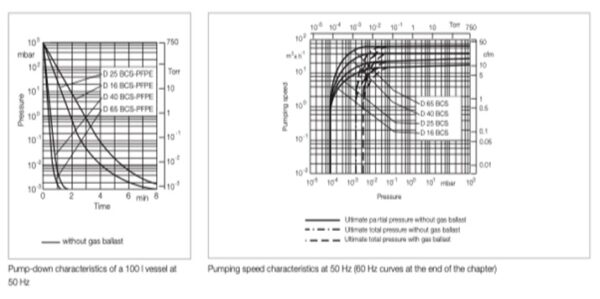

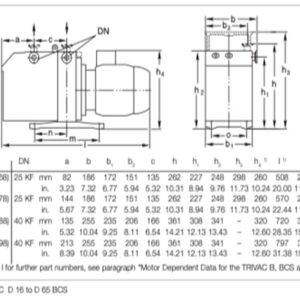

| Nominal pumping speed m3/h (cfm) | 29 .5 (17 .4) |

| Pumping speed m3/h (cfm) | 25 .7 (15 .1) |

| Ultimate partial pressure without gas ballast mbar (Torr) | 10-4 (≤ 0.75 x 10-4) |

| Ultimate total (pressure without gas ballast mbar (Torr) | 2.5 x 10-3 (≤ 1 .5 x 10-3) |

| Ultimate total (pressure with gas ballast Stage mbar (Torr) | 5x 10-3 (≤ 0.75 x 10-3) |

| Oil filling, min . / max .l (qt) | 0 .6 / 1 .4 (0 .6 / 1 .5) |

| Noise level dB(A) | 54 / 56 |

| Admissible ambient temperature°C (°F) | +10 to +40 (+50 to +104) |

| Motor ratingW (HP) | |

| Nominal speedrpm | 1425 |

| Weight (with oil filling) kg (lbs) | 32 .3 (71 .2) |

| Connections (Intake and Exhaust) DN | 25KF |

| Weight (with oil filling) kg (lbs) | 32 .3 (71 .2) |

Compact design

Low noise operation with hardly any vibrations

Built-in oil pump

Continuous operation even at 1000 mbar (750 Torr)

Pressure-lubricated sliding bearings

Anti-suckback valve controlled via the oil pressure, no ackstreaming of oil, independent of the operating mode, with or without gas ballast

Low backstreaming of oil within the pump

High pumping speed down to ultimate pressure

Either vertical or horizontal intake and exhaust ports

All controls as well as the oil sight glass are located on the face side

Low power consumption

Produces very little heat

Exchangeable inner section

Main flow oil filters may be fitted

Very long service life

Modular system

Service-friendly

Built-in temperature switch for temperature monitoring

Corrosion protected – the use of yel- low metals has been avoided; only grey cast iron, surface treated alu- minium, steel and stainless steel is used

Double shaft seal

| Power Voltage: | 3 pha 380V-400V, 50-60Hz |

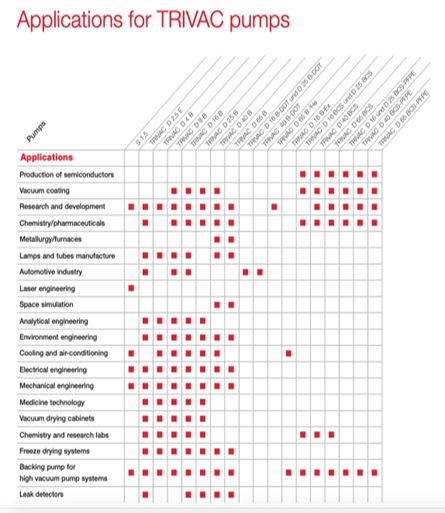

In all areas of vacuum engineering

Pumping of corrosive or aggressive media

Production of semiconductors and in the area of chemistry

Research and production

Generation of rough and medium vacuum

Backing pump in pump sets, i .e . in connection with Roots, diffusion, turbo or cryopumps

with 3-phase motor

200 – 240/380 – 400 V, 50 Hz /

200 – 240/380 – 480 V, 60 Hz 1)

219 − 242 V / 380 − 420 V, 50Hz,

200 − 240 V (200 V IE3) /

380 − 400 V (380 − 400 V IE 3), 50 Hz /

200 − 240 (208 − 240 V IE3) /

400 − 480 V (416 − 480 V IE3), 60 Hz

180 − 220 V (200 V IE3 Japan) /

311 − 380 V (346 V IE3 Japan), 50 Hz / 200 − 240 V (220 V IE3 Japan) /

342 − 418 V (380 V IE3 Japan), 60 Hz

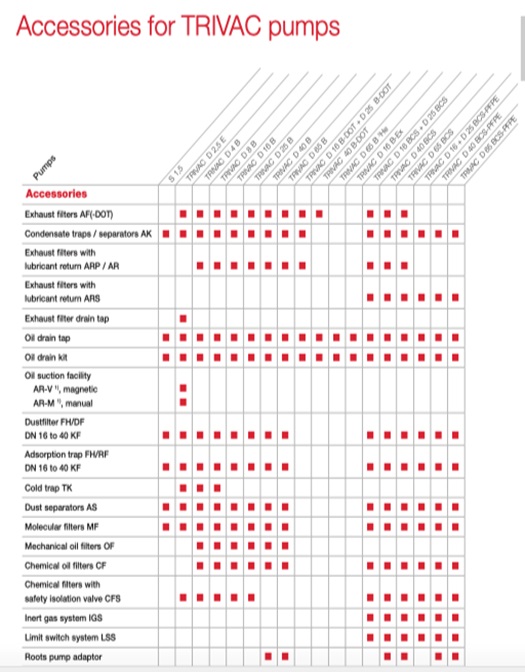

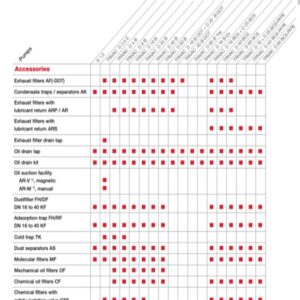

Roots pump adaptor

Exhaust filter with lubricant return

Condensate separator

Chemical filter with safety blocking valve

Inert gas system

Limit switch system

Inner body

Major maintenance kit for LVO 100 (without oil)

Minor maintenance kit for LVO 100 (without oil)

Shaft sealing replacement kit

Seal kit

Small parts kit

Seal kit

Additional information

| Manufacturer | Leybold |

|---|---|

| Origin | Germany |