Wet Bench Model 8771

The wet benches proposed can be:

Manual

Semiautomatic

Automatic

Wet bench structures can be realized using different materials. According to used chemicals and/or to special customer’s requests. Types of plastics we used: PPS, PE, PVDF, FM 4910. In case of use of solvents, the wet bench structure will be made in electropolished stainless steelL SS 304, SS 316L. Other system parts will also comply with chemical used, to warrant: minimum contamination, system elevated life, safety.

Manual wet benches are usually employed in laboratories of simple processes, where repeatablility is not so strict and where an automatic unit won’t be exploitable in all its capabilities.

The manual version, according to working plan configuration, can be equipped with specific components, as per customer’s specifications.

+ Refilling: A wet bench chemical refilling can be done in different ways:

– Directly from CDS-BCS

– From bottle/canister refilling system, intergrated into wet bench

– From bottle/ canister refilling system, housed in a separate module

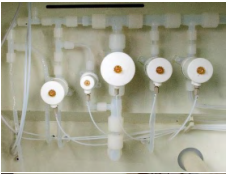

+ Hydraulic parts: water group components are the fundamental parts that compose a wet bench, because they must: transfer solution, filter, recycle, heat, chill, maintain the desired temperature, dosing chemicals.

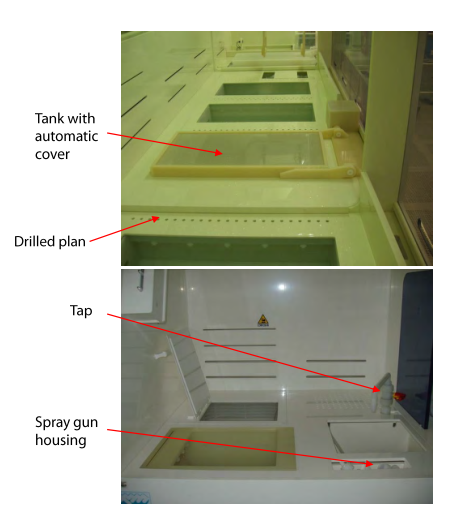

+ Manual wet bench main components: valves, pumps, filters, heat exchangers and chillers, fittings, dosing sytems, working plan ( includes: spray-gun, tap, tank,…), general control.

- Description

- Additional information

Description

HIGHLIGHTS

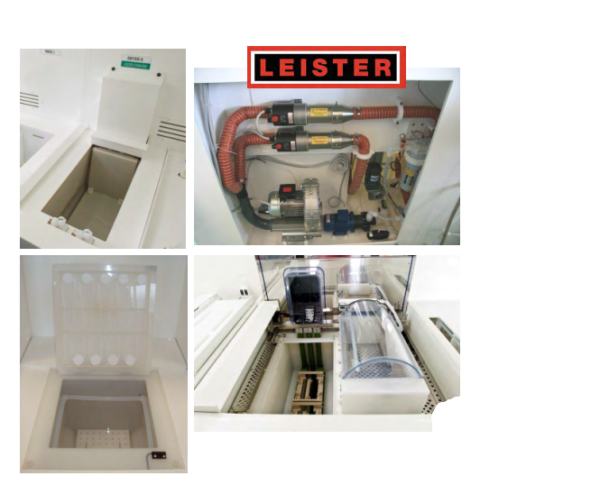

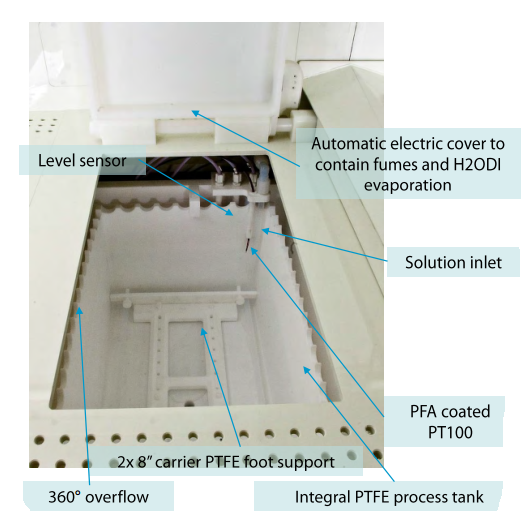

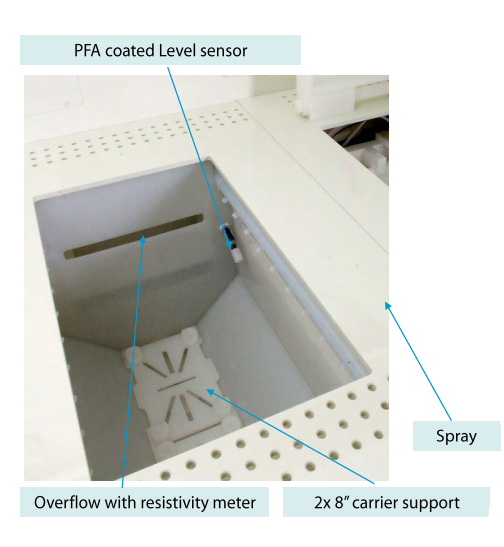

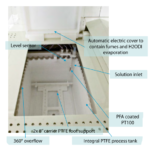

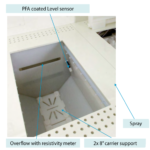

Rinse, process and dryer tanks are designed and realized by SPM using only top performance materials and latest construction technologies.

| Cover | white PPS |

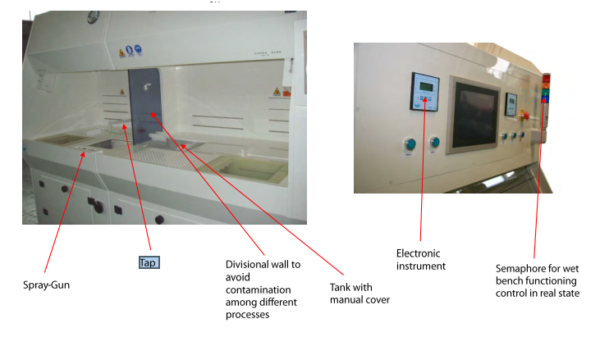

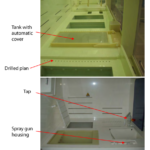

| 2 PVDF tank with: * Manual cover * Manual drain * 1 Goose neck tap for H2O DI * 1 Goose neck tap for Hot H2O * Localized exhaust | 200x200x250mm (LxDxH) |

| Equipment Kind (Transparent door for access to the working plan): Hood |

| N. 1 embedded spray gun for H2O DI |

| N. 1 embedded spray gun for N2 |

| Additional safety tank with leakage sensor (hydric group area on the backside) |

| Piping system: under the equipment and the backside. |

| Led lamp for internal lighting |

| Exhaust: in the top bench, centralised exhaust system, with outlet connection Ø160mm. |

| The structure is duly supported from bottom by a fraim in anodized aluminium, with pivoting wheels for easier transport and level controls for correct positioning. |

| General control module with electric board, process timers, etc. for complete control of all parts. |

| Remaining working plan area free, will be drilled (PPS white). |

| Power | Volt: 220V Phase: Monophase Power: 1W Current: 1A Frequency: 50/60Hz |

| N2 | Connection: F. NPT Material: PP Diam: 3/8” Pressure Min: 3,5 BAR Pressure Max: 4 |

| DRAINS | Type: General drain Material: PP Connection: F.Gas Diam: Ø1″ |

| Type: Safety drain Material: PP Connection: F.Gas Diam: Ø1″ | |

| Type: Acid drain Material: PP Connection: F.Gas Diam: Ø 1-1/4″ | |

| INLETS | Fluid: H2ODI Material: PVDF Connection: F.Gas Diam: Ø1/2″ |

| Fluid: Hot H2ODI Material: PVDF Connection: F.Gas Diam: Ø1/2″ | |

| EXHAUST | Type: Acid Connection type: PVC Flange Diameter: Ø 160 Min rate (m3/h): 1200 m3/h Max rate (m3/h): 1600 m3/h |

– Semiconductor: Wafer/Mask processing and cleaning, equipment parts cleaning

– Photovoltaic: iso texturing, cells recycling

– Research Centers / Labs: Hood for laboratory, equipment parts cleaning, chemical processes

| Connectors and piping: Stainless steels |

| General control unit with PLC and touch screen Proface brand |

| UP/DW in motorized version |

| Semaphore unit at 4 colours with buzzer |

Updating….

Additional information

| Manufacturer | S.P.M. Special Plastic Module |

|---|---|

| Origin | Italy |

| Type | Manual |