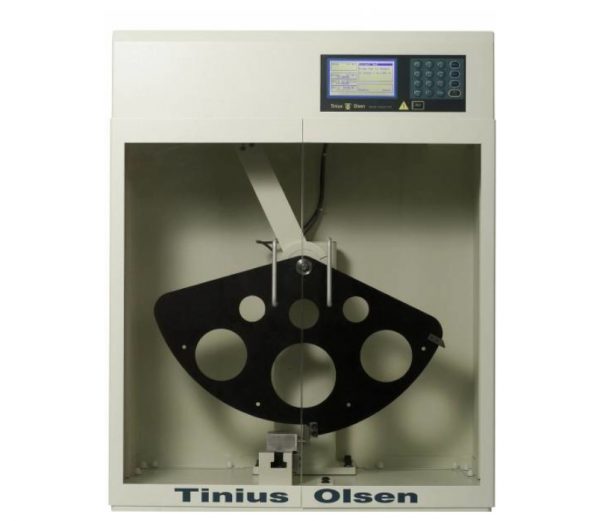

Low Pendulum Impact Model IT 503 & 504

The model IT 503 plastics impact tester, together with the model IT 504, continues to set the industry standard for versatility, ease of operation, and display of information with high resolution.

The primary difference between the IT503 and the IT504 is that the model IT504 is supplied without the interlocking safety shielding.

The user attaches the appropriate striking tup on the pendulum and the specimen clamp or anvils in the base of the unit, to test plastics in accordance with ASTM D256 (Izod impact), ISO 179 (Charpy impact), ISO 180 (Izod impact), ASTM D6110 (Charpy Impact), ASTM D4812 (Unnotched Cantilever Beam Impact), ASTM D4508 (Chip Impact), ASTM D950 (Adhesive Bond Impact), and other similar standards.

- Description

- Additional information

Description

HIGHLIGHTS

Aerodynamic compound pendulum

Automatic or manual Toss correction

Auto calibration for bearing windage and friction

Automatic or manual update of specimen number

Selectable energy units of J, in.lbf, ft.lbf, kgf.m and kgf.cm

Break type input options of Complete, Hinge, Partial, Non-break, and Necking

Selectable impact resistance / strength calculations in ft.lbf/in, J/m, in.lbf/in, kgf.m/m, ft.lbf/in2, kJ/ m2, in.lbf/in2, or kgf.m/m2

Real time display of energy is available for verifying the display accuracy against traceable measurements of pendulum height and weight.

On the model IT503, interlocked safety doors to ensure pendulum cannot be released with these doors open

| Specifications | unit | |

| BASIC PENDULUM CAPACITY

| j | 2.82 |

| t.lb | 2.08 | |

| in.lb

| 25

| |

| WITH LOW BLOW

| j | 2.75 to 2 |

| t.lb | 2.03 to 1.475 | |

| in.lb

| 24.38 to 17.73

| |

| INCREASED PENDULUM CAPACITY

| j | add-on weights available for up to 25 J |

| t.lb | add-on weights available for up to 18.44 ft.lb | |

| in.lb

| add-on weights available for up to 221.63 in.lb

| |

| DROP HEIGHT

| m | 0.61 |

| ft

| 2

| |

| IMPACT VELOCITY | m/s | 3.46 |

| t/s | 11.35 |

| The aerodynamically designed compound pendulum provides maximum rigidity in the direction of the impact and virtually eliminates any windage losses. Pendulum capacity is easily changed by adding on any one of seven optional weight sets. | ||

| The energy absorbed in breaking the specimen can be configured in SI, metric, or English units and is determined by an optical encoder mounted on the shaft of the machine and is based on the latched height of the hammer (relative to the zero potential energy point), the maximum post-impact height of the hammer, and the frictional losses of the machine. Energies of less than 0.03% of the pendulum capacity can be resolved and this resolution is vastly superior to dial type displays and other currently available displays. | ||

| The IT 503 is supplied as standard with a “low blow” feature which provides a convenient and reliable means for releasing the pendulum from a lower than usual height, so allowing testing at lower impact velocities and energy levels. | ||

| Additionally, the model IT 503 is supplied with all necessary interlocked safety shielding to protect the operator and bystanders from the broken samples. | ||

| To make impact testing on plastics easier and more flexible, the machines can be connected to a pc running Tinius Olsen’s Horizon software for data capture and analysis. | ||

| The standard capacity range of the machine using the compound pendulum is from 2J to 2.82J; this can increased to a maximum of 25J on the compound pendulum, using different weight sets to take you to capacities of 5J, 50in.lb, 7.5J, 100 in.lb, 15J, 200in.lb, and 25J. Outside of this range, the compound pendulum needs to be replaced by individual pendulums. | ||

| Optional pendulums available have capacities of 0.5J, 1J, and on the other end of the spectrum, 50J. The primary difference between the IT503 and the IT504 is that the model IT504 is supplied without the interlocking safety shielding. |

| POWER | 110/220 VAC, 50/60 Hz, 1ph |

| DIMENSIONS W x D x H | 660 x 380 x 840 mm |

| 26 x 15 x 33 in | |

| WEIGHT | 110 (90) kg |

| 240 (200) lb |

In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged.

In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.

In plastic industry, the test is used for analyzing the breaking strength of a sample when it is subjected to a high impact from a pendulum. This helps in ensuring that the material is best for an application where it is subjected to such impacts.

Low temperature chambers

the machine has been equipped with cold box (top cover removed). Liquid nitrogen is the typical medium used to cool the specimen.

Separate hammers

Separate 0.5J, 1J and 50J hammers

Interlocked doors

The model complies with CE requirements and cannot operate if the interlocked doors are open.

Compound pendulum, strikers and supports

Selection of add-on weights for compound pendulum, strikers and supports.

Charpy configuration

Charpy configuration, with the horizontal specimen on supports in front of the anvils.

Izod configuration

Izod configuration shown, with one end of the specimen clamped in position.

MODEL 899 SPECIMEN NOTCHER

The Tinius Olsen Model 899 Impact Specimen Notcher for Plastics is designed to machine a notch in a plastic specimen in accordance with ISO 179, ISO 180 (type A notch specimen), ASTM D256 and ASTM 6110.

The Model 899 Specimen notcher features an air cooling system that directs air flow at the cutting area to reduce the risk of thermal degradation of the specimens. A clear safety cover over the cutting area protects the operatorwhile doubling as an attachment for a vacuum system (not supplied) to remove chips from the cutting area.

The Model 799 Notch Depth Verification Device.

After the notching process is completed, the notch depth can be verified by using the Model 799 Notch Depth Verification Device. Optional cutting tools are available to produce ISO type B and C notches.

Horizon Software

Computer assisted data acquisition and machine control system which can be supplied with most Tinius Olsen testing equipment. The Horizon software package allows data to be collected, analyzed, graphed (where appropriate), and stored. If the testing machine allows, it can also provide control over testing operations.

Horizon has a comprehensive selection of pre-defined testing programs which includes powerful analysis of testing data, complex control, and sophisticated reporting. These programs can be modified and further enhanced to fit a customer’s particular requirements. The testing data collected by these programs may be exported to an outside source then later transferred to other data analysis systems. The Horizon databases may also be configured to be shared across several computers on a company’s network thereby allowing the testing programs and testing data to be utilized by multiple systems.

Using Horizon will make easy work of your materials testing, whether it’s designed for the demanding rigors of R&D or the charting and analysis functions of QC testing.

Key Features Overview

| Advanced Machine Segment Control |

| Customizable Report Layout |

| Data Archiving and Backup |

| Data Exporting (Results/Limits/Statistics/Points) |

| Data Importing (Result Entries/Limits) |

| Data Stored with SQL Server Express |

| Formula Generation |

| Library of Pre-Defined Testing Programs |

| Method/Output Editor |

| Multiple Graphs/Reports for Output |

| Multiple Machine Controlled by one Horizon |

| Multiple Users |

| Networking Databases |

| Report Consolidation |

| RS232 Device Communication |

| Security Lockout Capability |

| Touchscreen Capability |

| Video Extensometer Capability |

Test & Recall

The testing area allows for the viewing of live data from the machine while the test is being performed. Multiple tabs showcase the recalling of previous testing data as well as each testing machine connected to the software. Once a testing tab is created, it never has to be destroyed. When a new testing program needs to be run, simply change the Tab Options and load a new program. Each testing tab can be configured to display custom results, multiple graphs, multiple plots on a single graph, and live data (including custom formulas). Each tab may be customized to suite a user’s preferences.

Method/Output Editor

The testing program transferred from the Library may be customized for the customer in the Method and Output Editors. Create custom batch/sample identifiers for reporting and recalling purposes. Enhance the control of the machine with advanced machine segments. Automatically accept tests then print or email the report based on pre-defined limits. Customize multiple reports for various recipients. Import specimen data (such as dimensions or limits) from an outside file based on an identifier. Export results, limits, statistics, and/or curve points to an external file.

Custom Results

Methods transferred from the Library contain a number of results which have been standardized. In the Result Editor, however, custom result can be created. Such results can might be defined as entry type, a single point along a curve, a calculation between two points along a curve, a live source, or even a calculated formula. Depending upon how the result is created, it can be added to a testing panel to be viewed during the test or added to a report.

Library of Methods

A searchable database containing a variety of pre-defined testing routines. These methods are based on Standards from ASTM, ISO, EN, BS, DIN and many more. These routines include testing in tension, compression, flexure, torsion, melt index, heat distortion, hardness, impact, and more. Each method may be transferred into the user’s main database and customized with their own identifiers, units, report layouts, etc. With each new version update of Horizon, more and more routines are added to the Library.

Help Desk

Access to the tutorials which guide a user is various activities in the software.Displays details of the Software Key including items purchased. System Information displays valuable data regarding the software as well as the computer which it is installed upon. This guides the Tinius Olsen support staff when there are questions regarding system functionality. Please also note this page offers quick access to the Horizon QS program which will allow our Tinius Olsen support staff to take control of the computer when assistance is requested.

Additional information

| Manufacturer | Tinius Olsen |

|---|---|

| Origin | USA |

| Type | Manual |