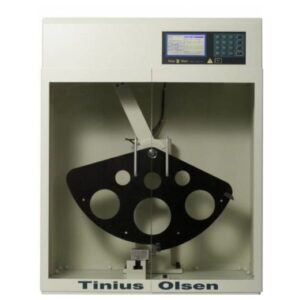

Pendulum Impact Model IT 800

Tinius Olsen has increased the range of capacities with the Model IT800, with 800 J (590 ft•lb) of available energy.

The IT 800 incorporates a number of unique features including a follower arm that tracks the swinging pendulum withou contact and if the test area safety doors are opened (or optional light curtain broken) immediately stops any further motion of the pendulum. This follower arm also acts as the pendulum return carrier and safely returns the pendulum to its latched release point once a test is complete. Other features include a touch screen display to set-up the test and displaying the test results.

The IT 800 has a number of different features and accessories that ensure safe and reliable testing while maintaining accuracy and repeatability of the results. These features include, as standard on the IT800, a unique motorised following arm that acts as both an electric brake and a motorised return, safety shields with the choice of an interlocked door or a light curtain that prevent a pendulum release during specimen loading, lateral expansion gage, and a digital display that was developed with the same feel as our Horizon software.

All testing hardware is fully complemented by Tinius Olsen developed Horizon software that turns your hardware into a sophisticated quality analysis system.

- Description

- Additional information

Description

HIGHLIGHTS

Precision, friction compensated, robust test frames.

Digital display option allows test set-up and result display

Safety features ensure repetitive secure testing

Digital display option allows simple connection to PC for full test SPC analysis.

| Specifications | unit | |

| Pendulum capacity

| J | 800 |

| ft.lb

| 590

| |

| Drop height

| m | 1.5 |

| ft

| 5

| |

| Pendulum weight

| kg | 62 |

| lb

| 136

| |

| Impact velocity

| m/s | 5.5 |

| ft/s

| 18

|

| Precision, friction compensated, robust test frames. | ||

| Digital display option allows test set-up and result display. | ||

| Digital display option allows simple connection to PC for full test SPC analysis. | ||

| Safety features ensure repetitive secure testing |

| Dimensions* (WxDxH) | 2560 x 910 x 2320 mm |

| 101 x 36 x 92 in | |

| Weight | 2631 kg |

| 5800 lb |

In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged.

Charpy configuration

The specimen rests horizontally on the Charpy supports. Centering tongs can be seen in front .

Replaceable shrouds prevent the specimen from rebounding against the pendulum. The striker is bolted to the pendulum and available in 8mm (ASTM E23) or 2mm (BS, DIN, JIS, EN, and ISO) nose radius sizes. An optional set of selfcentering tongs is useful for accurately centering specimens, especially those subjected to temperature extremes before the test

Horizon Software

Computer assisted data acquisition and machine control system which can be supplied with most Tinius Olsen testing equipment. The Horizon software package allows data to be collected, analyzed, graphed (where appropriate), and stored. If the testing machine allows, it can also provide control over testing operations.

Horizon has a comprehensive selection of pre-defined testing programs which includes powerful analysis of testing data, complex control, and sophisticated reporting. These programs can be modified and further enhanced to fit a customer’s particular requirements. The testing data collected by these programs may be exported to an outside source then later transferred to other data analysis systems. The Horizon databases may also be configured to be shared across several computers on a company’s network thereby allowing the testing programs and testing data to be utilized by multiple systems.

Using Horizon will make easy work of your materials testing, whether it’s designed for the demanding rigors of R&D or the charting and analysis functions of QC testing.

Key Features Overview

| Advanced Machine Segment Control |

| Customizable Report Layout |

| Data Archiving and Backup |

| Data Exporting (Results/Limits/Statistics/Points) |

| Data Importing (Result Entries/Limits) |

| Data Stored with SQL Server Express |

| Formula Generation |

| Library of Pre-Defined Testing Programs |

| Method/Output Editor |

| Multiple Graphs/Reports for Output |

| Multiple Machine Controlled by one Horizon |

| Multiple Users |

| Networking Databases |

| Report Consolidation |

| RS232 Device Communication |

| Security Lockout Capability |

| Touchscreen Capability |

| Video Extensometer Capability |

Test & Recall

The testing area allows for the viewing of live data from the machine while the test is being performed. Multiple tabs showcase the recalling of previous testing data as well as each testing machine connected to the software. Once a testing tab is created, it never has to be destroyed. When a new testing program needs to be run, simply change the Tab Options and load a new program. Each testing tab can be configured to display custom results, multiple graphs, multiple plots on a single graph, and live data (including custom formulas). Each tab may be customized to suite a user’s preferences.

Method/Output Editor

The testing program transferred from the Library may be customized for the customer in the Method and Output Editors. Create custom batch/sample identifiers for reporting and recalling purposes. Enhance the control of the machine with advanced machine segments. Automatically accept tests then print or email the report based on pre-defined limits. Customize multiple reports for various recipients. Import specimen data (such as dimensions or limits) from an outside file based on an identifier. Export results, limits, statistics, and/or curve points to an external file.

Custom Results

Methods transferred from the Library contain a number of results which have been standardized. In the Result Editor, however, custom result can be created. Such results can might be defined as entry type, a single point along a curve, a calculation between two points along a curve, a live source, or even a calculated formula. Depending upon how the result is created, it can be added to a testing panel to be viewed during the test or added to a report.

Library of Methods

A searchable database containing a variety of pre-defined testing routines. These methods are based on Standards from ASTM, ISO, EN, BS, DIN and many more. These routines include testing in tension, compression, flexure, torsion, melt index, heat distortion, hardness, impact, and more. Each method may be transferred into the user’s main database and customized with their own identifiers, units, report layouts, etc. With each new version update of Horizon, more and more routines are added to the Library.

Help Desk

Access to the tutorials which guide a user is various activities in the software.Displays details of the Software Key including items purchased. System Information displays valuable data regarding the software as well as the computer which it is installed upon. This guides the Tinius Olsen support staff when there are questions regarding system functionality. Please also note this page offers quick access to the Horizon QS program which will allow our Tinius Olsen support staff to take control of the computer when assistance is requested.

Additional information

| Manufacturer | Tinius Olsen |

|---|---|

| Origin | USA |

| Type | Manual |