SOGEVAC SV 630 B/630 BF/750 B/750 BF

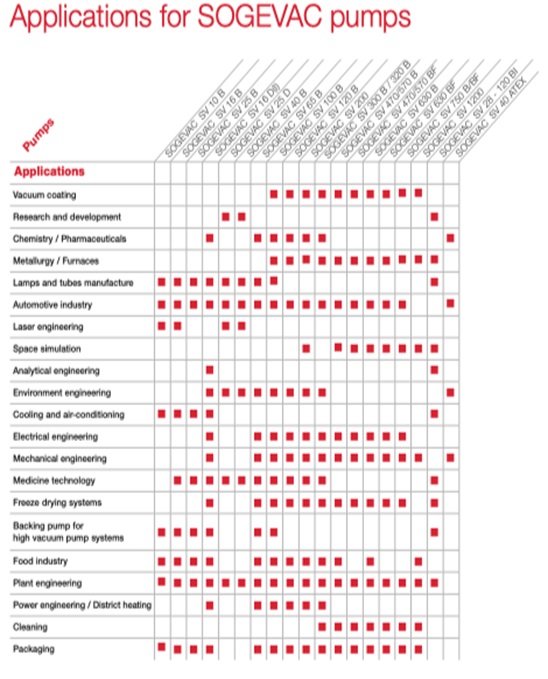

Oil sealed rotary vane vacuum pumps are being used in all areas of vacuum engineering . They are equally suited for both industrial production and research applications .

- Description

- Additional information

Description

HIGHLIGHTS

They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots vacuum pumps or high vacuum pumps . The SOGEVAC pumps excel also to their low noise levels and smooth operation .

Protection of the Environment

The built-in exhaust filter ensures an oil-mist free exhaust gases over the entire range of operating pressures from atmospheric pressure to ultimate pressure .

Many years of experience in vacuum engineering and the latest developments in pump technology combine in the SOGEVAC range the capability to adapt to the requirements of both the industry and the environment . The comprehensive range (pumping speeds ranging from 10 to 1200 m 3 x h -1 (5 .9 to 707 cfm)) allows every customer to select the right pump for his particular needs .

Quiet Operation

SOGEVAC pumps are designed throughout to keep the noise level as low as possible . This is ensured by optimized running and sliding speeds and the selection of low-noise drive motors, as well as perfected manufacturing techniques using CNC automatic machines for optimized tolerances and reproducibility of the individual components .

Anti-Suckback Valve

A valve is built into the intake of the SOGEVAC pumps . This “anti-suckback valve” is protected by a metal wiremesh filter . During standstill of the pump (for example due to shutting down or a power failure) the valve closes the intake . This prevents the pressure from rising in the connected chamber while the pump is vented at the same time . Any suck-back of pump oil into the vacuum system is thus also effectively prevented . This blocking process operates under all operating conditions (below 800 mbar (600 Torr)) and even when the gas ballast valve is open .

Compact Design

The pumps have been so designed that efficiency of the pumps will be high .

For the SV 10 B through SV 65 B, the motor and pumping section use the same shaft . For the SV 100 B to SV 1200 the motor is linked depending on requirements to the pumping section directly via a coupling or via V-belts as a pedestal motor . All vacuum components like anti-suckback, exhaust filter with oil return line needed for a complete vacuum unit as well as the optimized placement of all controls and monitoring components allow for an extremely compact unit .

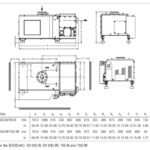

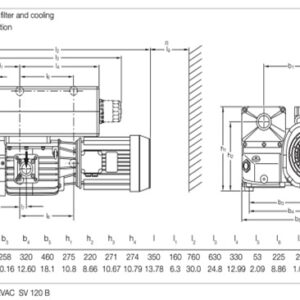

| Nominal pumping speed m3/h (cfm) SV630 SV750 | 700 (412.0) 840 (494.4) |

| Pumping speed m3/h (cfm) SV630 SV750 | 640 (376.7) 755 (444 .4) |

| Ultimate total (pressure without gas ballast mbar (Torr) | < 8 x 10(< 6 x 10-2) |

| Ultimate total (pressure with gas ballast Stage mbar (Torr) | ≤ 0,7 (≤ 0 .5) ≤ 2 (≤ 1 .5) |

| Oil filling, min . / max .l (qt) | 20 / 23 |

| Noise level dB(A) | 72/75 |

| Admissible ambient temperature°C (°F) | 12 to 40 (54 to 104) |

| Motor KW(HP) | 15/18.5 |

| Cooling | water or air |

| Nominal speedrpm | 820/1000 |

| Weight (with oil filling) kg (lbs) | 750 |

| Connections (Intake and Exhaust) DN | 100 PN 10 / 100 ISO-K Option 4) |

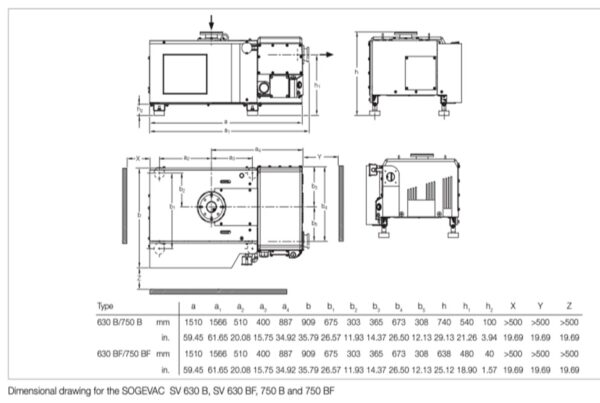

| Height x Width x Depth | 1510 x 909 x 740 |

| Weight | 750 |

| Simplified maintenance thanks to an easy access to all key components |

| Very low rotational speed increases the lifetime of the pump and leads to noise level reduction |

| Adaptors for direct mounting of Roots pumps (RUVAC WH 700 to 2500) |

| Small size |

| Extremely low noise level in any working conditions |

| ATTEX IIC T3 Cat . 3 version internal/ external possible |

| Air or water-cooling and many motors and options available |

| Reduced number of oil pipes |

| PFPE versions available |

| Competitive price-to-performance ratio |

| Reduced operational costs |

| Long lifetime of oil and exhaust filters |

| Power Voltage: | 3 pha 380V-400V, 50-60Hz |

| Water cooling |

| – Coating systems and load locks |

| – Oil purification |

| – Plastic & rubber injection presses |

| – Heat treatment / Metallurgy |

| – Lamination |

| – ATEX and O2 applications |

| – and more . . . |

| with three-phase motor, 230 V / 400 V, 50 + 60 Hz / 460 V, 60 Hz 230 V / 400 V, 50 Hz |

| Adaptor for Roots pump RUVAC 700 RUVAC 1001 RUVAC 2001 RUVAC WHU 2500 |

| EM gas ballast kit, 24 V DC |

| Exhaust filter monitoring gauge |

| Oil level check |

| Temperature switch |

| Water cooling with thermostatic valve |

| Exhaust filter overpressure switch |

| Oil filter bypass |

| Oil filter, standard |

| Exhaust filter AFE SV630/SV750B/SV300B (5 pieces are required) |

| Intake filter element Paper, meatal, actived charcoal Polyester |

| Seal kit FPM (FKM) |

| Repair kit, complete |

| Generator kit |

| Maintenance kit |

Additional information

| Manufacturer | Leybold |

|---|---|

| Origin | Germany |