3D Optical Profilometer ContourX-500

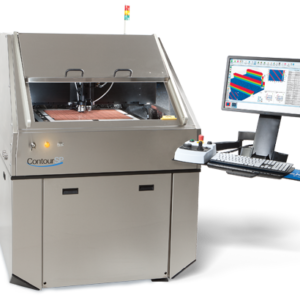

The ContourX-500 Optical Profilometer is the world’s most comprehensive automated benchtop system for fast, non-contact 3D surface metrology. The gage-capable ContourX-500 boasts unmatched Z-axis resolution and accuracy, and provides all of the industry-recognized advantages of Bruker’s white light interferometry (WLI) floor-standing models in a much smaller footprint. The profiler is easily customized for the widest range of complex applications, from QA/QC metrology of precision machined surfaces and semiconductor processes to R&D characterization for ophthalmics and MEMS devices.

- Description

- Additional information

Description

HIGHLIGHTS

Automation capabilities

Enable routines for faster measurement and analysis.

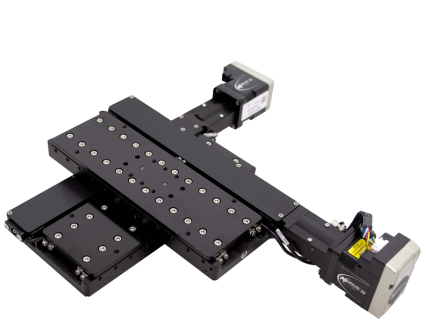

Motorized XY stage

Provides low-noise, high-speed operation for quantitative metrology.

Vibration-tolerant compact design

Delivers measurement stability and gage-capable repeatability.

| – Max. Scan Range | ≤10 mm |

| – Vertical Resolution | <0.01 nm |

| – Step Height Accuracy | <0.75% |

| – Step Height Repeatability | <0.1% 1 sigma repeatability |

| – Max Scan | 37 μm/sec (with standard camera) |

| – Max. Sample Slope: | ≤40° (shiny surfaces); ≤87° (rough surfaces) |

| – Sample Height: | ≤100 mm (4 in.) |

| – XY Sample Stage | 150 mm (6 in.) encoded automation stage |

| – Z Focusing | Automated |

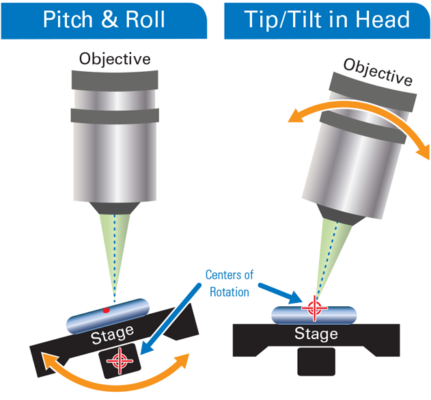

| – Tip/Tilt Function: | ±5° automated in head |

| – Objectives | Parfocal: 2.5X, 5X, 10X, 20X, 50X, 115X; LWD: 1X, 1.5X, 2X, 5X,10X; TTM: 2X, 5X, 10X, 20X; Bright Field: 2.5X, w5X, 10X, 50X |

| – Camera | Monochrome (standard) or color (optional); 5 MP with 1200×1000 data array |

| – Automation | Advanced automated stitching, scatter, and grid automation standard with encoded motorized XY stage; auto focus; auto intensity; auto saving; on-fly analysis; and recording into database |

| – Calibration | Via NIST/PTB traceable step height and lateral ruler standards |

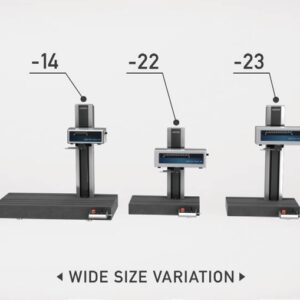

| – System Footprint | 480 mm (W) x 604 mm (D) x 700 mm (H) |

| – Weight | 70 kg |

Designed for Unmatched Benchtop Metrology

Bruker’s proprietary tip/tilt in the head provides unmatched user flexibility for production setup and inspection. By coupling the auto tip/tilt functionality with the optical path in the microscope head, Bruker has coupled the point of inspection to the line of sight independent of tilt. This results in less operator intervention provides the maximum reproducibility. Other hardware features include an innovative stage design for larger stitching capabilities and a 5MP camera with a 1200×1000 measurement array for lower noise, larger field-of-view, and higher lateral resolution. The combination of these features with automated staging and objectives makes the ContourX-500 ideally suited to “measure-on-demand” R&D and industrial metrology, all within a compact footprint.

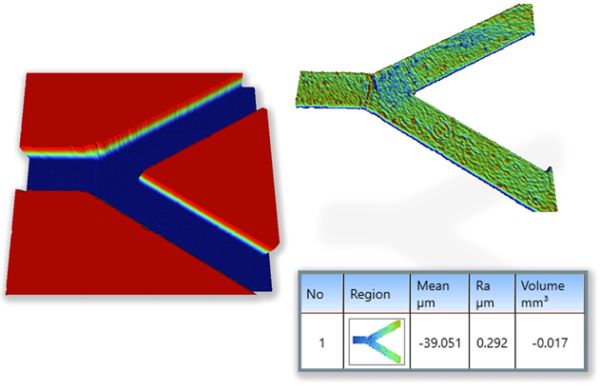

Streamlined Access to Extensive Analysis

With thousands of customized analyses and Bruker’s simple-to-use, yet powerful VisionXpress™ and Vision64® user interfaces, the ContourX-500 is optimized for productivity in the lab and on the factory floor. Bruker’s new Universal Scanning Interferometry (USI) measurement mode provides fully automated, self-sensing surface texture, optimized signal processing while delivering the most accurate and realistic computation of the surface topography being analyzed.

Updating…..

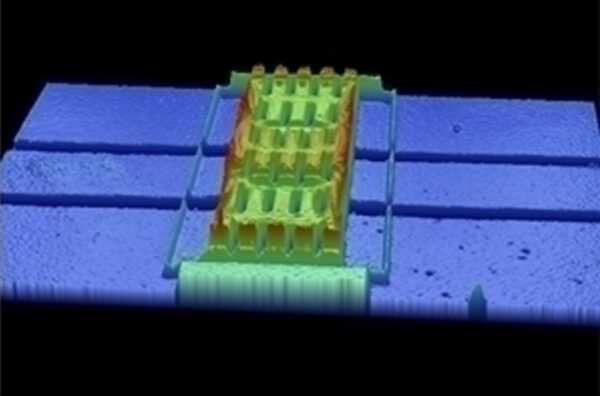

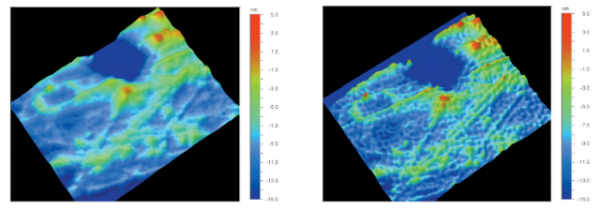

3D Optical profilometer are widely used as process motoring tools because they can quickly cover a large area, and are very versatile. They are best to be used for critical dimension, film thickness, and roughness measurements. They can also be used for defect detection and analysis.

Key application areas:

•Automotive/Aerospace

•Data Storage

•Solar

•MEMS

•Semiconductor

•LED, Optics

•Medical

•Precision Machining/Tribology

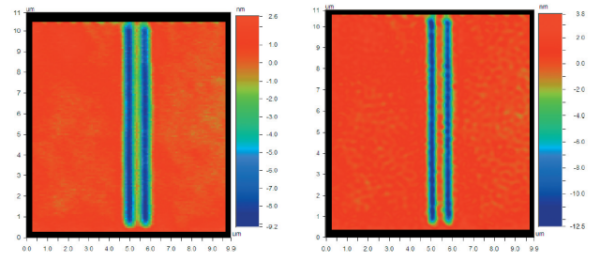

AcuityXR

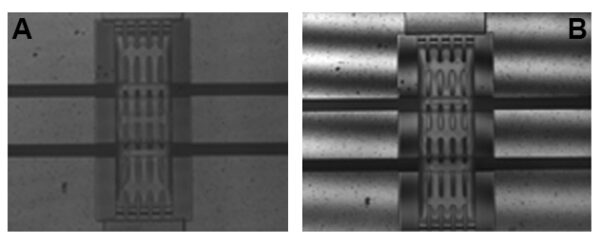

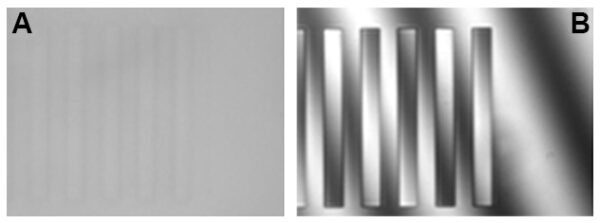

AcuityXR® combines unique, patent-pending Bruker hardware and software technology to enable select Contour 3D optical surface profilers to break the optical diffraction limit and deliver lateral resolutions previously considered unattainable with conventional optical microscopy techniques. It works on smooth surfaces where the phase of the reflected light is used to calculate surface height from the white-light-interferometric signal, improving sharpness, clarity, and definition of scratches, defects, and surface texture. Additionally, dimensional repeatability on nanoscale structures is improved by a factor of 5X.

|  |

Through Transmissive Media

“Enables high-resolution measurements through protective packaging, environmental chambers and other dispersive materials

– Measure samples through glass and other materials up to 3mm thick

– Innovative illumination enables up to 40x measurements

– Universal housing supports multiple magnifications and compensation materials

– 20x objective offers 25:1 aspect ratio for deep trench measurements

– For MEMS, materials science, biological applications, and more”

|

|

|

|

Upgrade Your Optical Profiler

Maximize your productivity with system hardware and software upgrades

– Hardware Upgrades

+ Computer Upgrade

The new Dell Precision computer with Windows 10 and the latest version of Vision64, version 5.70 enables new measurement capabilities, improved security, and enhanced remote support.

+ Automated FOV

The three position automated FOV allows quick swapping of FOV lenses from your computer.

+ Motorized XY Stage

+ Motorized XY Stage

The 6-inch automated XY stage enables stitching and stage automation.

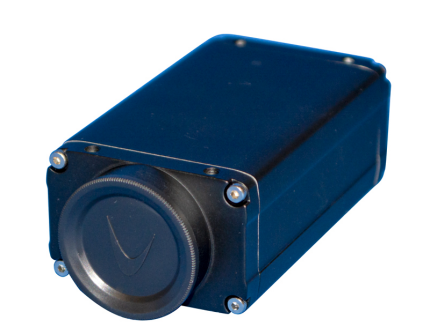

+ High-Resolution Cameras

Bruker offers a selection of color and monochrome cameras to meet your application needs.

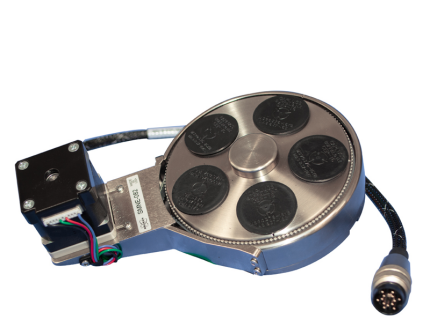

+ Automated 5-Position Turret

The automated five-position turret provides quick, efficient switching of objectives and adds objective parcentricity when used with a motorized XY stage. For use with all Bruker par-focal objectives.

+ Objectives and FOV Lenses

Increase capability of your optical profiler with Bruker objectives and FOV lenses. Bruker offers objectives with 1.5x to 115x magnifications.

– Software Upgrades

– Software Upgrades

+ AcuityXR Enhanced Resolution Measurement Mode

The AcuityXR measurement mode enhances the lateral resolution when using PSI (Phase Shifting Interferometry) or VXI measurement modes with the benefit of maintaining an equivalent field of view at higher resolution. It combines unique, patent-pending, hardware and software technology to enable select 3D Optical Surface Profilers to break the optical diffraction limit and deliver lateral resolutions that are traditionally unattainable with conventional interferometry techniques.

– Optical Metrology Module: Optional automated or manual

turret; Optional motorized or manual discrete modules.

– Camera: color

Vision64 and VisionXpress Analysis Software on Windows 10 OS; 64-bit

With thousands of customized analyses and Bruker’s simple-to-use, yet powerful VisionXpress™ and Vision64® user interfaces, the ContourX-500 is optimized for productivity in the lab and on the factory floor. This unique hardware and software combination provide streamlined access to highly repeatable and high-throughput metrology measurement over-classing comparable metrology capabilities.

Additional information

| Manufacturer | Bruker-nano |

|---|---|

| Origin | Germany |

| Type | Manual |