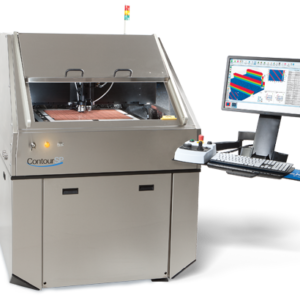

3D OPTICAL PROFILOMETER HD9800+

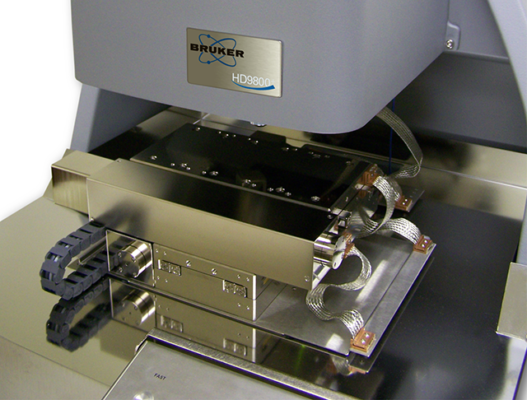

The HD9800+ 3D Large Format Surface Profiling System is the world’s most advanced optical profiler for in-line data storage slider metrology. The system combines the gauge-capable optical characterization technology with advanced automation to enable optimized PTR and flatness measurement performance. HD9800+ incorporates decades of industrial HD metrology experience using white light interferometry (WLI), self-calibration, LED high-intensity illumination, operator-friendly software, and a host of other features to provide the robust, high-resolution, non-destructive performance that data storage manufacturers need to improve process quality and increase yield.

- Description

- Additional information

Description

HIGHLIGHTS

Full automation

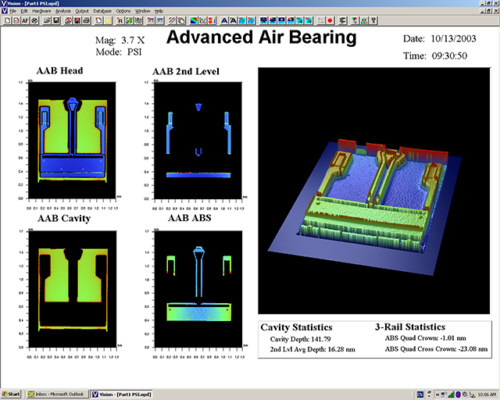

Delivers high-speed slider CCT and PTR characterization.

Patented tip/tilt head

Enables fast automated metrology with highest repeatability.

Streamlined software

Simplifies operator-to-operator use of data storage analyses and reporting.

| – Measurement Type | Non-contact, 3D surface |

| – Optical Objectives | 1.5X, 2.5X, 5X, 10X, 20X, 50X, 100X; Optional: TTM objective |

| – FOV Multipliers | 0.55X, 0.75X, 1X, 1.5X, 2.0X |

| – Measurement Array | 640×480 standard; 1392×1040 high-resolution optional |

| – Stages | Automated 100mm Z axis, 200mm XY stage; Optional 300mm XY stage |

| – Vertical Measurement Range | 0.1nm to 10mm |

| – Vertical Resolution | <0.01nm |

| – RMS Repeatability | 0.004nm |

| – Vertical Scan Speed | Up to 80μm/sec, user-selectable |

| – Lateral Spatial Sampling | 0.1 to 13.2μm |

| – Optical Resolution | 0.38μm/min (based on Sparrow criteria at 600nm wavelength) |

| – FOV | 8.45mm and optional stitching for larger FOV |

| – Reflectivity | Range from 0.1 to 100% |

| – Step Height Metrology | 0.6% absolute accuracy on 2μm step |

| – Footprint: | 1245mm (W) x 775mm (D) x 1550mm (H) |

Benchmark for Precision

The HD9800+ system’s vibration-tolerant design, integrated air isolation, and production-friendly architecture driven by industry road maps maintain measurement integrity during production floor usage. It’s high-resolution camera delivers the ultimate in lateral resolution and accuracy, and a wide range of hardware and analysis software features designed specifically for advanced process control result in the fastest and most gauge-capable system for data storage slider applications.

Best PTR and Flatness Capabilities

HD9800+ provides the fastest, most accurate 3D measurements for slider pole tip recession (PTR) and slider bearing surface flatness. The system also continuously calibrates to an internal, primary standard, eliminating the need for regular calibration to step heights. This self-calibration ensures long term stability and correlation, and significantly reduces qualification time. The ultimate result is the most accurate industrial metrology performance with the best reliability and serviceability on the market.

Updating…..

Bruker’s HD9800+ provides the fastest, most accurate 3D measurements for slider pole tip recession (PTR) and slider bearing surface flatness. Featuring a robust system design and production-friendly architecture driven by industry road maps, the system exhibits superior immunity to production floor vibration and noise.

| – Optical Objectives |

| Optional TTM objective |

| – Measurement Array |

| 1392×1040 high-resolution optional |

| – Stages |

| Optional 300mm XY stage |

| – Dual Accu Phase (DAP) software |

| Delivers absolute PTR metrology correlation to baseline AFM benchmarks for variable material sliders. |

| – SureVision software |

| Enables etch depth and position measurements without operator intervention via automatic pattern recognition of features of interest |

| – Light tower |

| Highlights operational status to factory floor personnel |

| – Bar code scanner |

| Delivers streamlined material and workflow handling |

Vision 4.41 running under Windows 7, 32-bit platform

Additional information

| Manufacturer | Bruker-nano |

|---|---|

| Origin | Germany |

| Type | Automatic |