Upright Material Science Microscopes UM 800

> Reflected light microscopy is the choice for imaging opaque samples. The sample is illuminated from above through the objective. Because light is unable to pass through opaque samples, it is directed on the surface and returned to the objective by reflection

> Upright reflected light microscope has two eyepieces, normally 10x magnification, and, in most cases, a tube head dedicated for using a camera system, this connection is normally on the viewing tube.

> The nosepiece is capable of holding from four to six objectives, these can be recognized by the Epi tag on their external cover.

> Mechanical stage sample holder can be moved in the XY axis , while the entire stage can be moved up and down through coarse and fine focusing mechanism. In certain configurations these movements can be automated by using motorized stage systems.

> The illumination system is built-in with dedicate lamp housing, the generated light passes through a vertical illuminator between the nosepiece and below the viewing tube head.

> The sample is placed upside down on the stage with the surface to be observed facing the objective.

> Several techniques are commonly used: Brightfield, Darkfield, Polarized light and Differential Interference Contrast (DIC).

- Description

- Additional information

Description

HIGHLIGHTS

Microscopes is designed to supply state-of-the-art reliability and cost/efficient high performance

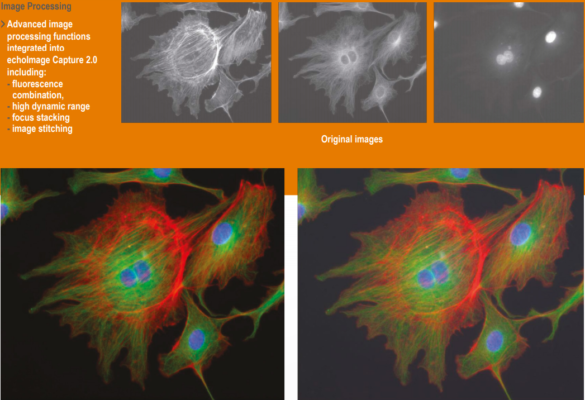

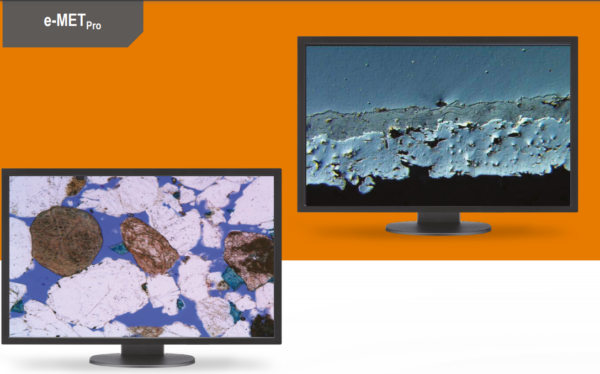

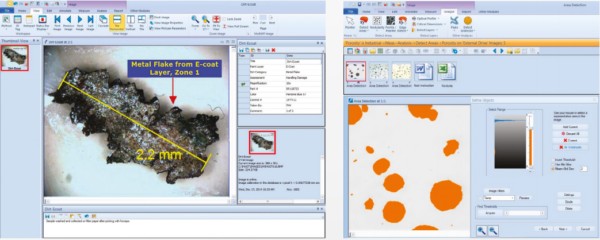

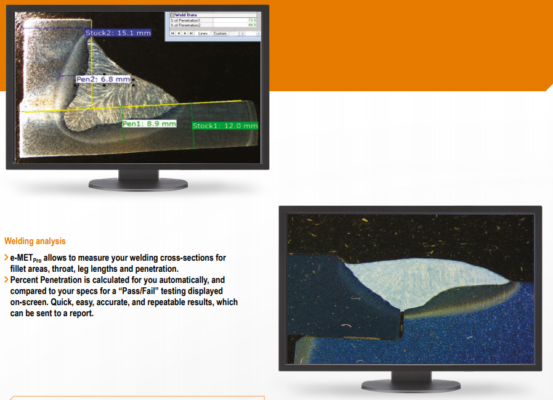

echoLAB offers also necessary accessories, high performance cameras and different software from basic image capture (included with the camera) to advanced automated image analysis for particle sizing and metallurgical analysis (e.g. grain size, inclusion counts, porosity etc).

Software is leading-edge digital imaging software for a wide variety of metallurgical applications, for labs set up, for quality control or quality assurance, production, inspection, failure analysis and research

| Optical system | CCIS |

| Total magnification | 50x – 100x – 200x – 400x |

| Eyepiece | WF 10x (ø22mm) |

| Plan achromatic objectives long working distance | PL L 5x/0.12 WD=26.10mm |

| PL L 10x/0.25 WD=20.20mm | |

| PL L 20x/0.40 WD=8.80mm | |

| PL L 40x/0.70 WD=3.68mm | |

| Head | Trinocular |

| Inclination of 30° | |

| Interpupillary distance 55mm-75mm | |

| Diopter adjustable ±5 | |

| Nosepiece | Quadruple back ball bearing inner locating |

| Stage | Mechanical stage overall size 160x160mm |

| Glass working stage 360° rotatable, scale 1° | |

| Coaxial motion 50x50mm | |

| Handwheel | Separating capability: 0.001 (digital display) |

| XY digital resolution: 0.001mm | |

| Handwheel scale: 0.01mm | |

| Focusing System | Coaxial coarse/fine focus system, minimum division of fine focusing 1μm |

| Tensional adjustable with upper stop | |

| Reflected illumination | 5W LED lamp, brightness control |

| Transmitted illumination | 5W LED lamp, brightness control |

| Polarization | Internal polarizer |

| Analyzer | 360° rotatable analyzer |

| Filter | Blue for reflected light |

| Green for reflected light | |

| Yellow for reflected light | |

| Contrast techniques | Brightfield: Yes |

| Darkfiled: Not available | |

| DIC: Not available | |

| POL Contrast: Yes | |

| Power supply | 230V ±10% – 50/60Hz -1Ph – 30W |

> Upright reflected light microscope has two eyepieces, normally 10x magnification, and, in most cases, a tube head dedicated for using a camera system, this connection is normally on the viewing tube.

> The nosepiece is capable of holding from four to six objectives, these can be recognized by the Epi tag on their external cover.

> Mechanical stage sample holder can be moved in the XY axis , while the entire stage can be moved up and down through coarse and fine focusing mechanism. In certain configurations these movements can be automated by using motorized stage systems.

> The illumination system is built-in with dedicate lamp housing, the generated light passes through a vertical illuminator between the nosepiece and below the viewing tube head.

> The sample is placed upside down on the stage with the surface to be observed facing the objective.

> Several techniques are commonly used: Brightfield, Darkfield, Polarized light and Differential Interference Contrast (DIC).

| Power suply | 230V ±10% – 50/60Hz -1Ph – 30W |

| Computer | Yes |

> Reflected light microscopy is the choice for imaging opaque samples. The sample is illuminated from above through the objective. Because light is unable to pass through opaque samples, it is directed on the surface and returned to the objective by reflection.

> Most common samples are : metals, plastic materials, wood, silicon, ceramics etc

| UM E-800-01 Eyepiece 10x (ø18mm) crosshair 0.1mm/Div. |

| UM O-800-21 Long working distance objective PL L 50x/0.70 WD=3.68mm |

| UM O-800-22 Long working distance objective PL L 80x/0.80 WD=1.25mm |

| UM O-800-23 Long working distance objective PL L 100x/0.85 WD=0.40mm |

| UM Dk-800-81 DIC kits |

| UM CA-800-91 Camera adapter 0.5x |

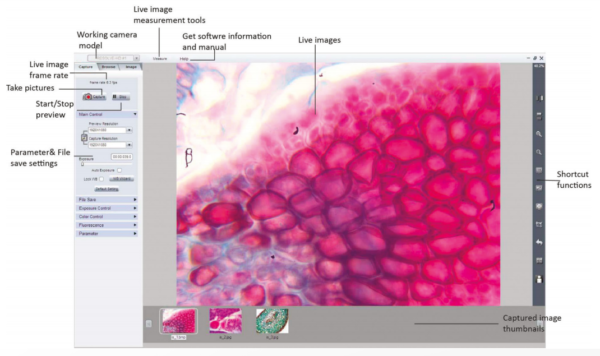

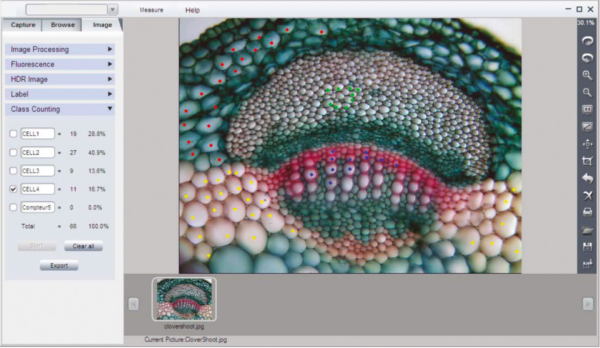

User-friendly interface, complete camera parameter control, | |

|

Additional information

| Manufacturer | Echolab |

|---|---|

| Origin | Italy |

| Type | Manual |