Automatic Dicing Saw DAD323

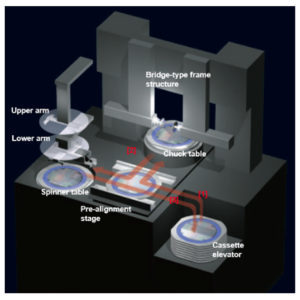

World’s Smallest* Dicing Saw which Supports Diversified Processing from Semiconductor Wafers to Electric Components

Max. workpiece size Φ150 mm

Single spindle

- Description

- Additional information

Description

HIGHLIGHTS

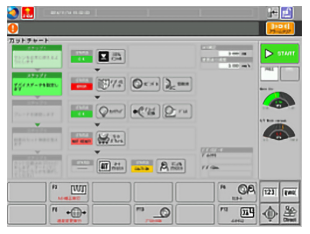

Diversified Processes

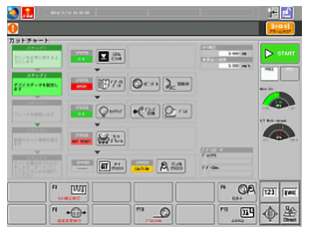

The DAD323 is a single-axis dicing saw with a 2.0 kW high-torque spindle, compatible with workpieces as large as 6 x 6 inches.

High productivity

Software operation speed and response speed are improved through adoption of a high-performance MCU. The axis speed is accelerated and throughput is improved by adopting servo motors for all three axes.

World’s smallest footprint*

DAD323 is a compact dicing saw with a width of only 490 mm, and greatly contributes to improvements in productivity per unit area when multiple units are lined up.

| Max. workpiece size | Φ6 inch / 150 mm × 150 mm (user-specified specification) | ||

| X-axis | Cutting range | mm | 160 |

| Cutting speed | mm/s | 0.1 ~ 800 | |

| Y-axis | Cutting range | mm | 162 |

| Index step | mm | 0.0001 | |

| Index positioning accuracy | mm | 0.005/160 (Single error)0.003/5 | |

| Z-axis | Max. stroke | mm | 32.2 (Φ2 inch blades) |

| Moving resolution | mm | 0.00005 | |

| Repeatability accuracy | mm | 0.001 | |

| θ-axis | Max. rotating angle | deg | 320 |

| Spindle | Output | kW | 2.0 at 40,000 min-1 |

| Rated torque | N.m | 0.48 | |

| Revolution speed range | min‐1 | 3,000 – 40,000 | |

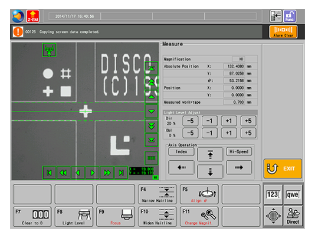

| Microscope section (alignment) | System | Pattern matching system based on the target patterns from the CCD camera | |

| Scope | 0.64 mm square | ||

| Magnification | ・7.5x (pixel size: 0.0013 mm) | ||

| Direct light (LED) + Ring light (LED)[optional accessory] | Ring light provides workpieces with 360 degree illumination to deal with various workpiece surface conditions and kerf angle after cut | ||

| Kerf check | ・Compensation on a hairline standard ・Kerf width max./min. ・Check setting of random locations ・Check setting for each cut line number | ||

| Automatic light intensity adjustment | |||

| Auto focus | |||

| Auto alignment | |||

| Device type change | Alignment conditions can be switched autodevice data are changed | ||

| Alignment accuracy | ± 0.0013 mm | ||

| Alignment capable die size | 0.4 mm or more | ||

| The auto alignment function is included as a standard feature. | |||

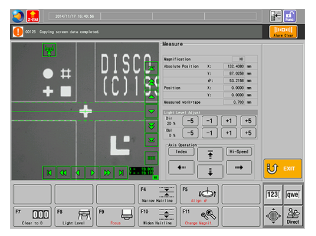

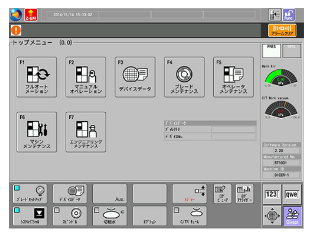

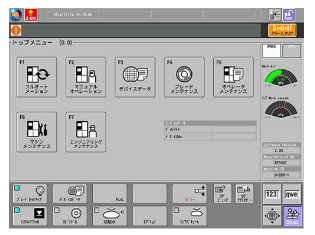

| Operation via a 15-inch monitor and a GUI (Graphical User Interface) | |||

| Large monitor for improved legibility and an increase in the amount of displayable information. | |||

| The auto alignment function is included as a standard feature. | |||

| Operation via a 15-inch monitor and a GUI (Graphical User Interface) | |||

| Large monitor for improved legibility and an increase in the amount of displayable information. | |||

| Installed with the same user-friendly operating system as the 3000 series (DAD322 compatibility mode is also supported) |

| Power supply | 200 ~ 240 V AC±10 %, 3-phase (50/60 Hz) |

| Power consumption | When processing 0.6 kW (for reference) and During warm-up 0.5 kW (for reference) |

| Max power | 3.5 kVA |

| Air pressure | 0,5 ~ 0,6 MPa |

| Air max consumption | 378,0 L / min (ANR) |

| Clean air pressure | 0,5 ~ 0,8 MPa |

| Clean air max. consumption | 162 L / min (ANR) |

| Pressure water cutting | 0,2 ~ 0,4 MPa |

| Max. flow rate Cutting water | 4 L / min |

| Pressure cooling water | 0,2 ~ 0,4 Mpa |

| Flow rate cooling water | 3.0 ở 0,3 MPa L / min |

| Exhaust duct capacity | 5,0 m3 / min |

| Machine dimensions(W x D x H) | 490 × 870 × 1,600 mm |

| Machine weight | Approx.400 kg |

| – semiconductor and electrical components manufacturer |

| – used in dicing and performs the cutting of the silicon wafer |

| USB flash drive | ||

| Duct cuffs | 32 50 | |

| Duct hoses | I.D. 32.0 2 m I.D. 50.6 2 m | |

| Pipe band | 35-38 53-60 | |

| Locating pin | For chuck table | |

| Wheel cover | Centrifugal for 2.0kW spindle (resin type) | |

| Flange specification selection | Hub specifications | Wheel mount set for hub |

| R-type flange specifications | 48.2 × 40.0 | |

| 49.4 × 40.0 | ||

| 50.6 × 40.0 | ||

| 52.0 × 40.0 | ||

| 54.0 × 40.0 | ||

| Attached manual selection | Japanese manuals | Safety Manual Installation Manual Operation Manual Data Maintenance Manual Maintenance Manual Technical Reference |

| English manuals | ||

| Label selection: The languages used for the labels on the machine outer cover | Japanese English German French Italian Chinese (Simplified) Chinese (Traditional) Portuguese Korean | ・Rotating blade ・Moving parts ・Hot surface ・Hazardous voltage ・Line voltage always present |

| 1.8kW spindle specification | ||

| Tape frame | ||

| Cassette | ||

| Starter kit for 2-inch hub mount | ||

| Starter kit for R-type flange | ||

| Spare 2-inch hub mount (for 2.0kW/1.8kW spindle) | ||

| 2-inch hub mount jig (spare) | ||

| Chuck table | ||

| Maintenance parts kit | ||

| General | ||

| Advanced | ||

| Lifting jig set | ||

| Axis metal fixture (spare) | ||

| Machine anchoring bracket | ||

| Braided hose | ||

| Braided hose joint | ||

| Pipe band | ||

| Non-contact setup | ||

| Abrasive material for non-contact setup sensor | ||

| Blade breakage detector | ||

| Wheel cover | ||

| Power cables | ||

| Transformer unit for use outside Japan (internal type) | ||

| Uninterruptible power supply | ||

| Booster pump unit | ||

| Water leakage sensor | ||

| Duct fan unit (internal type) | ||

| Water temperature control unit | ||

| Magnification of microscope (micro) | ||

| Macro microscope | ||

| Direct light specification | ||

| Ring light specification | ||

| Wheel coolant water (shower) flow switch | ||

| Wheel coolant water (blade cooler) flow switch | ||

| Flow rate controller for the wheel coolant water | ||

| Spare USB flash drive | ||

| Stylus pen | ||

| Spare manuals | ||

| Kerf center alignment | ||

| Slow-in cutting function | ||

| Measure alignment package | ||

| CE-marking specification | ||

| CC Filter unit | ||

| High pressure air blower | ||

| Linear scale (Y-axis) | ||

| Duct capacity measuring instrument | ||

| Anti-soiling porous chuck table |

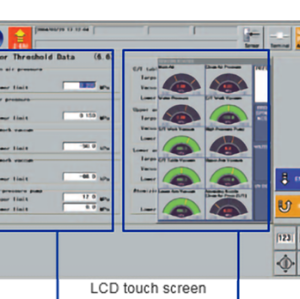

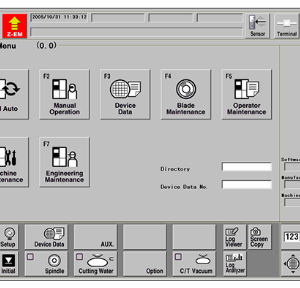

| Operation Control Screen | Indicates the directory name of the device data currently selected. |

| Indicates the device data No. currently selected. | |

| Indicates the software version installed in the machine. | |

| Indicates the machine management No. for DISCO. | |

| Indicates the machine ID specified on the USER DEFINE DATA 1 screen | |

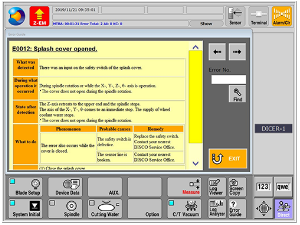

| Touch panel | A 15-type color LCD is employed to display alignment operation, cutting data, error messages, and other relevant information. It is also possible to operate the machine by directly touch the LCD. |

| Operation screens | Easy operation is realized by adopting GUI (Graphical User Interface). |

| Displayed guidance language | Can be selected from Japanese, English, Chinese (Simplified), or Chinese (Traditional). |

Additional information

| Manufacturer | Disco |

|---|---|

| Origin | USA |

| Type | Automatic |