Fully Automatic Dicing Saw DFD6361

Φ300 mm

Facing dual spindle

DBG (Dicing Before Grinding)

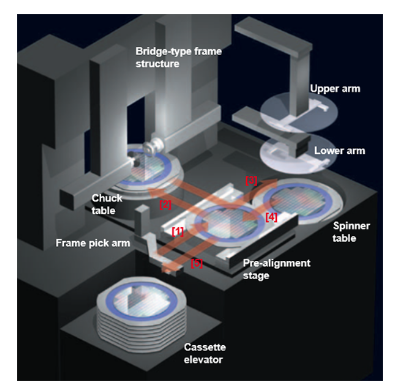

DFD6340 Operation flow

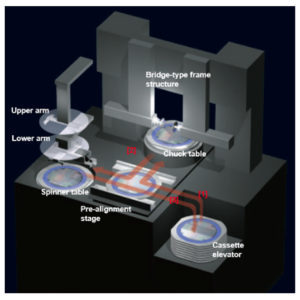

[1] Frame pick arm moves the workpiece from the cassette to the pre alignment stage → [2] After centering on the pre-alignment stage, the lower arm moves the workpiece to the chuck table → table → cutting → [3] Upper arm moves the workpiece to the spinner table → cleaning and drying → [4] Lower arm moves the workpiece to the pre-alignment stage → [5] Frame pick arm returns the workpiece to the cassette

- Description

- Additional information

Description

HIGHLIGHTS

Enhanced dicing throughput

The DFD6361 enhances throughput in two distinct ways. DISCO’s facing dual design and a reduction in distance between the blades help to control total cut time, while high-magnification microscopes (standard) and non-contact setup sensors (option) for both Z1 and Z2 reduce the time required for non-dicing sequences, such as kerf check and blade setup.

Consistent cut quality

DFD6361 offers highly consistent and dependable cut quality through the new Synchro Spindle™ featuring superior radial rigidity. An atomizing nozzle cleaning mechanism can also be installed in the spinner unit as an option to effectively clean wafers after dicing (Patent no.3410385).

Spindle lineup

The 1.2 kW spindle (standard) features superior rigidity. A center thrust design gives the 1.8 kW spindle (option, uses 2 ” blades) and the 2.2 kW spindle (option, uses 3 ” blades) extra rigidity for processing glass, ceramics, and other high processing load materials

Improved usability

Auto-open/close wheel cover and spindle shaft-lock feature make blade replacement quick and easy. In addition, the condition monitor relays processing status and key equipment information in real time. DFD6361 also has a cutting water flow rate control feature, making it possible to manage the flow rate on the screen. An adjustable LCD touch screen with GUI (Graphical User Interface) have also been adopted

| Specifications | unit | 1.2, 1.8 kW | 2.2 kW | |

| Max. workpiece size | mm | Φ300 | ||

| X-axis | Cutting range | mm | 310 | |

| Cutting speed | mm/s | 0.1 ~ 600 | ||

| Y1・Y2-axis | Cutting range | mm | 310 | |

| Index step | mm | 0.0001 | ||

| Positioning accuracy | mm | Within 0.002/310 (Single error) Within 0.002/5 | ||

| Z-axis | Max. stroke | mm | 14.7 (For Φ2 inch blade) | 14.9(For Φ3 inch blade) |

| Moving resolution | mm | 0.00005 | ||

| Repeatability accuracy | mm | 0.001 | ||

| θ-axis | Max. rotating angle | deg | 380 | |

| Spindle | Rated torque | N.m | 0.19(1.2 kW) 0.29(1.8 kW) | 0.7 |

| Revolution speed range | min‐1 | 6,000 ~ 60,000 | 3,000 ~ 30,000 | |

The spindle shaft-lock feature and auto-open/close wheel cover make blade changes easy and quick.

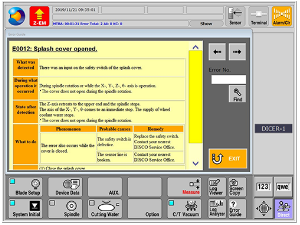

Condition monitoring functions relay processing status and key equipment information in real time.

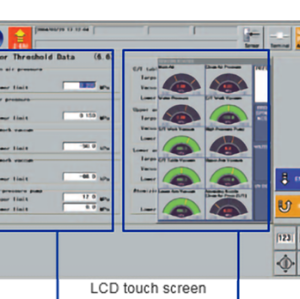

The cutting water flow rate controller is programmable via the touch-panel display and sets the flow rate for each process recipe.

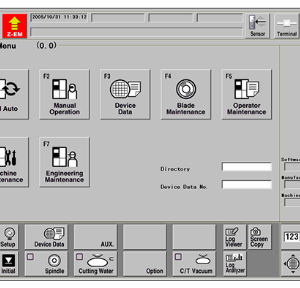

The easy-to-use graphical user interface is displayed on an adjustable touch-panel display.

| Power supply | 200 ~ 240 V AC±10 %, 3-phase (50/60 Hz) |

| Power consumption | When processing 2.2 kW (for reference) and During warm-up 1.8 kW (for reference |

| Max power | 6,9 kVA |

| Air pressure | 0,5 ~ 0,8 MPa |

| Air max consumption | 378,0 L / min (ANR) |

| Clean air pressure | 0,5 ~ 0,8 MPa |

| Clean air max. consumption | 265,0 L / min (ANR) |

| Pressure water cutting | 0,2 ~ 0,4 MPa |

| Max. flow rate Cutting water | 12 L / min |

| Pressure cooling water | 0,2 ~ 0,4 Mpa |

| Flow rate cooling water | 3.0 ở 0,3 MPa L / min |

| Exhaust duct capacity | 5,0 m3 / min |

| Machine dimensions | 1.200 x 1.550 x 1.800 mm |

| Machine weight | Approx.2,050 (without transformer for overseas use) |

| Approx. 2,150 kg (with transformer for overseas use) |

| – semiconductor and electrical components manufacturer |

| – used in dicing and performs the cutting of the silicon wafer |

Cassette and tape frame

High precision products to facilitate stable production from tape mounter to die bonder

Meets the ø300 mm wafer SEMI standard.

Automatic blade changer

Conducts blade change and resumes cutting fully automatically.

Minimizes the labour required and raises the utilization rate of the equipment.

Shorter set up time – two NCS* sensors

Two Non-Contact Setup sensors, one each for Z1 & Z2, enables increased throughput.

Updating…

Updating…

Additional information

| Manufacturer | Disco |

|---|---|

| Origin | USA |

| Type | Automatic |