Fully Automatic Dicing Saw DFD6450

Fully automatic dicing saw with parallel dual spindles

Φ200 mm

Package Singulation

DFD6450 Operation flow

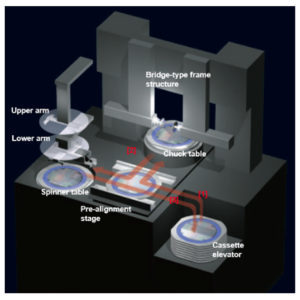

1/ Lower arm moves the workpiece from the cassette to the pre-alignment stage. Lower arm moves the workpiece to the chuck table → cutting → 2/ Upper arm moves the workpiece to the spinner table → cleaning and drying → 3/ Lower arm returns the workpiece to the cassette

- Description

- Additional information

Description

HIGHLIGHTS

A Parallel Dual Design Unique to DISCO

DFD6450’s parallel dual-spindle design, unique to Disco, has several benefits. Because the spindles are supported at the rear of the machine, they are easily accessible from the front for blade changes and other maintenance. Further, the design supports specialized applications such as multiple blades on each spindle for package singulation

Parallel Dual Dicing Saw with 6000 Series Features

Featuring parallel dual-spindles, DFD6450 combines the best aspects of predecessor DFD651 with the superior usability and process quality of the DFD6000 Series Dicing Saws. Designed to handle a wide range of dicing and grooving applications, DFD6450 processes silicon and compound semiconductor wafers, ceramics and other materials for electronic components, and glass and other materials for optical components.

A parallel dual design unique to DISCO

Featuring parallel dual-spindles, DFD6450 inherits the basic concept of the existing model, DFD651, and has been added to the DFD6000 series lineup with superior usability and processing quality.

| Specifications | unit | 1.0 kW | 2.2 kW | |

| Max. workpiece size | mm | Φ8 inch | ||

| X-axis | Cutting range | mm | 250 | |

| Cutting speed | mm/s | 0.1 ~ 600 | ||

| Y1 axis | Cutting range | mm | 250 | |

| Index step | mm | 0.0001 | ||

| Positioning accuracy | mm | Within 0.003/250 (Single error) Within 0.002/5 | ||

| Y2-axis | Cutting range | mm | 30 | |

| Index step | mm | 0.0001 | ||

| Positioning accuracy | mm | Within 0.002/30 | ||

| Z-axis | Max. stroke | mm | 35.2 | |

| Moving resolution | mm | 0.00005 | ||

| Repeatability accuracy | mm | 0.001 | ||

| θ-axis | Max. rotating angle | deg | 380 | |

| Spindle | Rated output | kW | 1 | 2.2 |

| Rated torque | N.m | 0.16, 0.24 (higher torque) | 0.7 | |

| Revolution speed range | min‐1 | 6,000 ~ 60,000、 3,000 ~ 40,000 (higher torque) | 3,000 ~ 30,000 | |

Improved usability

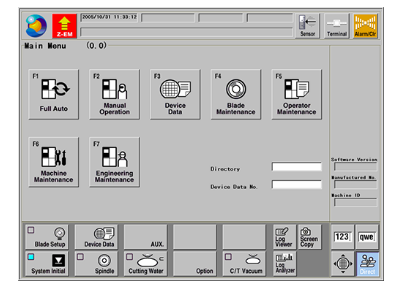

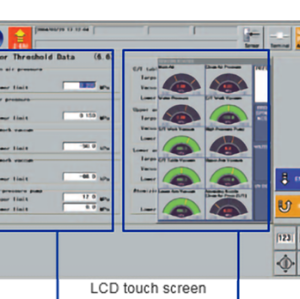

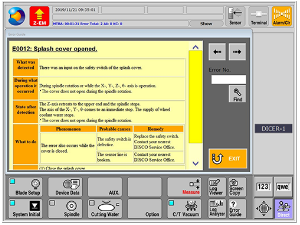

The 15-inch LCD touch panel with GUI (Graphical User Interface) allows for easy and intuitive operation. In addition, a spindle shaft-lock feature that automatically secures the spindle axis has been installed to make blade replacement quick and easy. DFD6450 also has a cutting water flow rate control feature, making it possible to set the cutting water flow rate for each set of device data.

Advanced options

The equipment can have a transformer, UPS, CO2 injector, or booster pump unit built-in by revising the equipment layout while maintaining an equipment footprint equal to that of the existing model. In addition, an atomizing nozzle mechanism (Japan patent no. 3410385) for the spinner section with high cleaning effect on workpieces and ionizer specifications for preventing electrostatic build up during workpiece transfer can be selected.

| Power supply | 200 ~ 240 V AC±10 %, 3-phase (50/60 Hz) |

| Power consumption | When processing 2.1 kW (for reference) and During warm-up 1.8 kW (for reference |

| Max power | 6,9 kVA |

| Air pressure | 0,5 ~ 0,8 MPa |

| Air max consumption | 378,0 L / min (ANR) |

| Clean air pressure | 0,5 ~ 0,8 MPa |

| Clean air max. consumption | 216,0 L / min (ANR) |

| Pressure water cutting | 0,3 ~ 0,4 MPa |

| Max. flow rate Cutting water | 12 L / min |

| Pressure cooling water | 0,3 ~ 0,4 Mpa |

| Flow rate cooling water | 3.0 ở 0,3 MPa L / min |

| Exhaust duct capacity | 5,0 m3 / min |

| Machine dimensions (W x D x H) | 1,120 x 1,500 x 1,600 mm |

| Machine weight | Approx. 1,400 kg (without transfomer for overseas use) |

| Approx. 1,480 kg (with transfomer for overseas use) |

| – semiconductor and electrical components manufacturer |

| – used in dicing and performs the cutting of the silicon wafer |

Cassette and tape frame

High precision products to facilitate stable production from tape mounter to die bonder

Meets the ø300 mm wafer SEMI standard.

Automatic blade changer

Conducts blade change and resumes cutting fully automatically.

Minimizes the labour required and raises the utilization rate of the equipment.

Updating…

Updating…

Additional information

| Manufacturer | Disco |

|---|---|

| Origin | USA |

| Type | Automatic |