SURFCOM C5

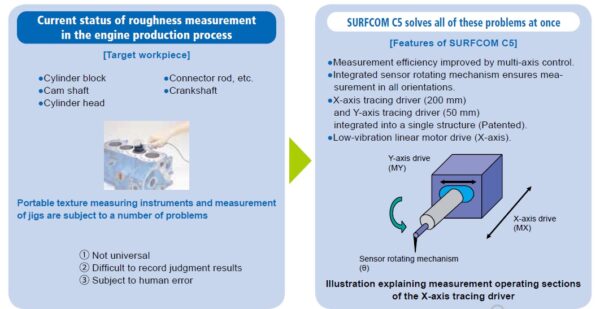

SURFCOM C5 allows customization of the workpiece feed unit and jig production to suit particular needs.

It is suited to workpieces that require appoach from many directions such as cylinder heads and blocks or workpieces that need a revolving shaft such as crank and cam shafts.

- Description

- Additional information

Description

HIGHLIGHTS

Fully automated CNC surface measurements for series production.

Measurement in all directions by rotatable probe head

Positioning speed of 100 mm/s for high measuring efficiency, even for large work pieces

| Measurement range: | |

| – Detector Z-axis (vertical) : | 1000 μm |

| -Tracing driver: X-axis (horizontal) | 200 mm |

| Operation range | |

| – Column up/down: Z -axis | 500 mm (resolution 0.1 µm) |

| – Tracing driver: X axis | 200 mm (resolution 0.1 µm) |

| – Column cross- feed: Y-axis | 800 mm (resolution 0.1 µm) |

| – Pickup tracing driver: Y- axis | 50 mm (resolution 0.1 µm) |

| – Pickup rotation angle | 0°, 90°, 180°, 270° Measuring pressure of 0.75mN is maintained at all orientations* |

| Tracing driver: Straightness acuracy | (X-axis) 0.5 μm/200 mm, (Y-axis) 0.5 μm/50 mm |

| Roughness processing function | |

| – Standard | Complies with JIS2001, JIS1994, JIS1982, ISO1997, ISO1984, DIN1990, ASME1995, CNOMO |

| – Surface characteristics graph | Bearing area curve, power spectrum curve, amplitude distribution graph |

| – Data point | 32000 max. (without λs filter); 300000 max. (with λs filter) |

| – Magnification (vertical) | 50, 100, 200, 500, 1 k, 2 k, 5 k, 10 k, 20 k, 50 k, 100 k, 200 k, 500 k |

| – Magnification (horizontal) | 0.1, 1, 2, 5, 10, 50, 100, 200, 500, 1 k, 2 k, 5 k, 10 k, 20 k |

| Speed | |

| – Column up/down speed (Z-axis) | 100 mm/s max. |

| – Tracing driver measuring speed (X-axis) | 0.03 mm/s to 3 mm/s (during roughness measurement), 0.03 mm/s to 20 mm/s (during waviness measurement) |

| – Tracing driver measuring speed (Y-axis) | 0.3 mm/s to 3.0 mm/s |

| Tracing driver moving speed (X/Y-axis) | 100 mm/s max. |

| – Column moving speed (Y-axis) | 100 mm/s max. |

| Detector | |

| – Stylus | Replaceable |

| – Measuring force (with DM43801 standard accessories) | 0.75 mN (with standard pickup) |

| – Stylus radius (with DM43801 standard accessories) | Rtip 2 μm (standard accessory) |

| – Weight | 2000 kg |

SURFCOM C5 allows customization of the workpiece loading unit and jig manufacturing according to customer requirements

The machine is suited to workpiecies that require approach from many directions such as cylinder heads and blocks or workpiecies that need a revolving shaft such as crank and cam shafts.

High throughput by Multi-Axis control

| – Power supply: | C100 to 240 V ±10%, 50/60 Hz, single phase |

| – Power consumption: | Maximum 1000VA |

| – Air supply: | 0.45 Mpa to 0.7Mpa, connection port: one- touch pipe joint for tubes with OD 8 mm |

The SURFCOM C5 has been developed for fully automatic surface measurement and quality assurance in production. It is ideal for crankshafts and engine components in series production.

The SURFCOM C5 features a massive granite construction and a specially developed active vibration table to minimize the environmental impact. The feed in the X direction is equipped with a vibration-free, low-maintenance and high-precision linear drive and provides additional stability.

– CNC stylus change

– Additional rotation axis and tailstock for fully automatic measurement of crankshafts and camshafts

Updating…

Additional information

| Manufacturer | Accretech |

|---|---|

| Origin | Japan |

| Type | Automatic |