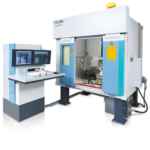

XLON MU2000-D Industrial X-ray System for Cast Parts Inspection

YXLON MU2000-D

– YXLON MU2000-D is a robust, reliable industrial X-ray and CT inspection system for broad applications in foundries, R&D, laboratories, universities, and educational institutions. The system delivers brilliant image quality with digital flat-panel detector and highly dynamic radioscopy.

– MU2000-D assists you in detection of flaws in items such as:

+ Aluminum castings (engine blocks, cylinders, cylinder heads, pistons, knuckles)

+ Turbine blades

+ Wheels and tires

+ Fiber+reinforced materials

+ Ceramics

+ 3D printed materials

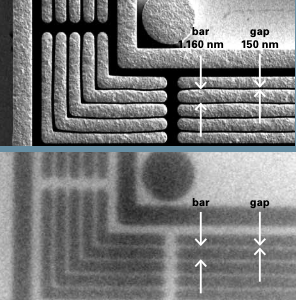

– The excellent image quality of the MU2000-D system is based on the interplay of the digital flat-panel detector array with our YXLON HDR-Inspect software. The HDR (Highly Dynamic Radioscopy) technology provides exceptional detail detection, even though varying material thicknesses, and assists in visually determining the depth of casting flaws.

– Thanks to the intuitive user interface, the MU2000-D is easy to operate, even for those without specialized knowledge. The same applies to the CT option. Our CT analysis station is equipped with industry leading software, VGStudio from Volume Graphics. You can count on detailed casting-flaw information thanks to 3D reconstruction of the CT scan. You can upgrade your MU2000 with the HDR and CT-option and benefit from these extended functions.

– MU2000-D is future-ready. Its interface generates data to be used in fields such as machine learning, Big data, the Internet of Things, and machine-to-machine communication. In order to ensure acceptable inspection quality of your safety-critical components, the MU2000-D complies with current industry standards like ASTM and specific car manufacturers’ requirements.

- Description

- Additional information

Description

HIGHLIGHTS

Renowned, robust, reliable digital X-ray inspection system

Brilliant image quality with high contrast for spot-check samples and series inspection

Fast computed tomography (CT scan) at the touch of a button (optional)

Smart ergonomics for easy operation

Tailor-made configuration for wheels and tires

Compliance with ASTM standards and specific car manufacturers’ inspection requirements

| Model | Y.MU2000-D Standard | Y.MU2000-D XL |

| 160/225/320/450 KV | 160/225/320/450 KV | |

| Inspection envelope/insp. item | ||

| Inspection envelope, radioscopy (diameter x height) | 600 mm x 900 mm | 800 mm x 1,500 mm |

| CT measuring cylinder (diameter x height), approx. | 170 mm x 150 mm | 180 mm x 160 mm |

| Inspection item weight | 60 kg (optional 200 kg) | 60 kg (optional 200 kg) |

| Object carrier | ||

| Rotary plate | 400 mm / 600 mm | 400 mm / 600 mm |

| Three-jaw chuck | 160 mm / 200 mm | 160 mm / 200 mm |

| Tilt angle beam path* | ± 30° (opt. ± 45°) / ± 20° | ± 30° (opt. ± 45°) / ± 20° |

| Cabinet/System | ||

| Width | 2,200/ 2,250/ 2,400/2,900 mm | 2,650/ 2,700/ 3,000/ 3,500 mm |

| Height | 2,700/ 2,750/ 2,750/ 2,800 mm | 3,300/ 3,350/ 3,500/ 3,550 mm |

| Depth | 1,800/ 1,850 / 1,950/ 2,500 mm | 2,050/ 2,100/ 2,200/ 2,750 mm |

| Weight | 4/6.5/10/19 T | 6/10/15/25 T |

| Cabinet door | ||

| Width x height, approx. | from 760 mm x 1,150 mm | from 1,100 mm x 1,700 mm |

| Open, close (motor-driven) | ~ 2/3/4/5 s | ~ 2/ 3/ 5/ 6 s |

| Detector | ||

| Active area | 200 mm x 200 mm | 200 mm x 200 mm |

| Pixel pitch | 200 µm / 400 µm | 200 µm / 400 µm |

| Frame rate (14-bit detector) | 15 fps / 30 fps | 15 fps / 30 fps |

| Distance X-ray tube – detector | 695 mm – 995 mm | 945 mm – 1,245 mm |

| Control console | ||

| Width x height x depth, approx. | 1,200 mm x 1,800 mm x 1,300 mm | |

| Power supply | 1 x 230 V, 50 Hz / 60 Hz | |

| Power input | max. 5 kW | |

| Weight, approx. | ~ 250 kg | |

Updating…

| Aerospace |

| Automotive |

| Foundries |

| Science & Research |

| Weld inspection |

| Y.Panel 0822-16 HDR premium |

| – 16 bit detector in YXLON premium-pixel quality, 1024 x 1024 pixel @ 200 µm with up to 25 fps, 512 x 512 pixel 400 µm with up to 50 fps.Suitable for film replacement for metal parts, especially in aerospace. Including housing with shielding and passive crash protection. The number of usable pixels may be reduced due to shielding. |

| – Acc. to YXLON specification, digital flat-panel detectors with premium grade quality show no “Center Kernel Pixel” respectively “relevant Cluster” acc. to ASTM 2597. |

| PC with Y.IMAGE 2500-D + ASTM window |

| Image enhancement, analysis and storage system for digital X-ray images with fast live image display and reference image functionality. The software is installed on the system PC. Major features are: |

| – Digital detector calibration using “Multi-Gain Correction” |

| – Intelligent correction of noisy and/or non-linear detector pixel |

| – File format DICONDE |

| – Measurement and text functions |

| – Various predefined filter sets |

| The ASTM reference image functionality is activated, the images themselves are part of an additional item. |

| ASTM E2973 DVD (Aluminum and Magnesium Die Casting) |

| Digital reference images acc.to ASTM E2973 on DVD and installed on the PC. Installed images are configured for a geometric magnification of two. Images for other geometric magnifications can be compiled acc. To the standard with the ASTM software tool. |

| Laser Cross |

| The laser cross has 2 line lasers that helps to depict the location of the central beam, thus simplifies the inspection part orientation for a faster application |

| IMAGE x500 | |

| IMAGE x500 imaging software is used for image evaluation. Its proven ease-of-use design is the result of a wide range of processing tools including filters, gray value scaling, annotations, and HDR live image filter, which make image processing and evaluation very convenient. |

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |