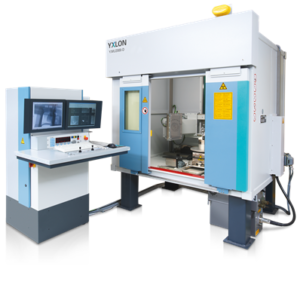

YXLON MTIS Leading X-ray System for Radial Tire Inspection

YXLON MTIS X-ray inspection system for radial passenger car and truck tires satisfies the need for the highest quality imaging and inspection accuracy, and gathers valuable statistical process control data.

Our MTIS industrial X-ray Inspection system is the perfect choice for 24/7 inline quality assessment of radial tires during final finishing, with a reliable uptime of more than 95%.

The system identifies defects and irregularities such as:

– Inaccurate positioning of structural steel components

– Defects of the components i.e. loose wires or dog ears

– Presence of foreign objects

The YXLON UScan 3 detector delivers high image quality with high contrast as required by ASTM F1035 with 16-bit dynamic resolution. The 4-spindle manipulator offers accuracy and easy reproducibility of the inspection results. This is the basis for gathering good statistical data. With the vertical scan positioning on the 4-spindle manipulator, inspection is achieved with a minimum of deformation, including for warm tires.

The automatic defect recognition software allows for objective and efficient quality assessment against specified limits and extracts various data for statistical process control for every tire, e.g. internal construction details that help make production quality measurable – an important role in continuous production improvement.

Our worldwide service network offers services tailored to your individual needs. We work to continuously improve the MTIS system to satisfy the latest industry requirements, helping you achieve a maximum reliability and exceptional uptime.

- Description

- Additional information

Description

HIGHLIGHTS

– Robust system for reliable 24/7 operation

– More than 350 systems in use worldwide

– Automatic X-ray image analysis powered by AI

– Delivery of all relevant data for production process optimization

– Fast new product introduction with EasyTeach wizard

| Y.MTIS PCR | Y.MTIS TBR | |

| Tire width | 00 – 400 mm / 4“- 15.5“ (with UScan 3-L) 100 – 350 mm / 4“- 13.5“ (with UScan 3-M) | 100 – 508 mm / 4“ – 20“ |

| Tire inner diameter | 13“ to 26“ tires 12“ on request | 13“ to 26“ tires |

| Max. tire weight | 60 kg / 132 lbs | 160 kg / 352 lbs |

| X-ray tube | 100 kV / 300 W | 100 kV / 300 W |

| Number of pixels | 2469 (with UScan 3-L); 1819 (with UScan 3-M) | 2469 (with UScan 3-L) |

| Pixel pitch | 500 μm | 500 μm |

| A/D converter | 16 bit | 16 bit |

| System dimensions | ~ 4,800 mm x 5,100 mm x 2,700 mm | ~ 5,400 mm x 5,100 mm x 2,700 mm |

WHEN MILLIMETERS MAKE THE DIFFERENCE

– 4-spindle tire manipulator proven in over 350 Y.MTIS systems worldwide.

– Vertical scan positioning ensures minimal deformation of the tire.

– Secure gripping assures repeatable positioning to the millimeter.

– Guaranteed accurate and reproducible inspection results.”

SAFE QUALITY DECISIONS THROUGH SOPHISTICATED TECHNOLOGY

– Shielded x-ray source uniquely improved for Yxlon to provide extremely stable operation

– Exclusive line detector Y.UScan3 designed and manufactured by Yxlon International

– Best image quality with highest contrast supporting 75 m/min rotation speed

– Advanced image enhancement tools for visual inspection based on decades of experience

SAFETY FIRST

– Proven safety according to latest German radiation laws (StrlSchV)

– Compliant to the European machinery directive and optionally to local standards such as OHSA/UL

– Installation and commissioning by Yxlon’s expertise

– State-of-the-art ergonomics

SEAMLESS INTEGRATION TO YOUR PRODUCTION LINE

– Standard conveyor interfaces

– MES connection interface

– Barcode reader solutions

– Site-specific integration support

RELIABLE RECOGNITION OF TIRE ANOMALIES ACCORDING TO YOUR QUALITY SPECIFICATION

Y.TireAXIS supports your operators with objective feedback based on your quality requirements evaluating the whole tire image all at once, comprising:

Alignment and Consistency of Tire Components

– Belt centering, width, angle, and belt wander

– Correct position or height of turnup and chafer

– Offset splices in belts, chafer, and turnup

– Kinked beads and loose bead wires

Analysis of Steel Cords

– Cord spacing, including crossed and touching cords

– Wavy cords

Detection of

– Foreign material and air voids

– Object presence evaluation (e.g. RFID tags)

Accurate Measurements of Interior Structures

Updating…

Y.TireAXIS supports your operators with objective feedback based on your quality requirements evaluating the whole tire image all at once, comprising:

Alignment and Consistency of Tire Components

– Belt centering, width, angle, and Belt wander

– Correct position or height of turnup and chafer

– Offset splices in belts, chafer, and turnup

– Kinked beads and loose bead wires

Analysis of Steel Cords

– Cord spacing, including crossed and touching cords

– Wavy cords

Detection of

– Foreign material and air voids

– Object presence evaluation (e.g. RFID tags)

– Accurate Measurements of Interior Structures

Updating…

TireView

TireView is our software dedicated for viewing tire X-ray images. It supports the display of high resolution 360° tire images and offers a wide variety of features for adjusting the image and investigating identified anomalies. It supports a live view mode with eye-friendly smooth scrolling to allow identifying minimal defects at a minimum viewer strain. TireView works with TireAXIS and highlights anomalies identified by the automatic defect recognition software.

TireAXIS

For fully automatic tire inspection, TireAXIS™ provides consistently high process quality to detect flaws in the cord material and plies, air inclusions or foreign objects, without any operator intervention. The software supports the operator or performs the final evaluation of the X-ray image independently. Configurable inspection programs offer reproducible decisions for a controlled testing process.

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |

| Type | Semiautomatic |