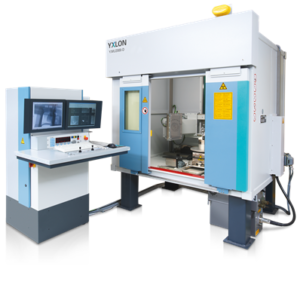

XLON MU2000-D Tire X-ray Inspection System for Tire on Wheel Applications

YXLON MU2000-D Tire

– Our MU2000-D is the perfect X-ray system when it comes to spot-check sample testing in wheel inspection. As the best-known standard inspection system from YXLON, we have sold more than 350 units since it was launched

– A reasonably priced, easy-to-operate system with a compact design and the newest radiographic technology gives it a convincing advantage when you add the “Tire on Wheel” option.

– MU2000-D Tire on Wheel real-time inspections reflect a distinct reduction in both time and costs. Outstanding detail detectability and simple, intuitive operation enables high throughput, without compromising the certainty of inspection decisions.

+ Radioscopic inspection of tires mounted on a wheel is used for examining tires under pressure and particularly the tire seat on the rim in R&D, production quality verification or failure root cause investigations.

+ Equipped with modern digital flat-panel detectors and YXLON HDR-Inspect technology, MU2000-D Tire on Wheel supplies brilliant image quality and high contrast

+ With MU2000-D Tire on Wheel, X-ray inspections can be carried out efficiently. Flaws in bead placement on the wheel are detected easily

+ Tread delamination, incorrect placement of tire subcomponents, or variances in thickness or tread of inner liner, sidewalls or tire tread can also be confirmed.

– The wheel is mounted on an axis that rotates automatically, enabling various inspection positions to be reached. With the help of tangential radiographic images across the entire 360° range, the tire’s inner alignment and belt plies position can be easily verified.

– Image acquisition features optimum resolution and dynamic images. When it comes to tire image processing and digital storage, image enhancement and archiving programs can be integrated.

- Description

- Additional information

Description

HIGHLIGHTS

Renowned, robust, reliable digital X-ray inspection system

Brilliant image quality with high contrast for spot-check samples and series inspection

Tailor-made configuration for wheels and tires

Economic solution for small batch sizes and sample tests

Small footprint fits into existing plant layouts

Quick release rotation axis for mounting tires for 360° inspection

| Model | Y.MU2000-D, 160 Kv |

| Inspection item | |

| Inspection item dimensions | Max. width 350 mm, Max. outer diameter 620 mm |

| Inspection item weight | Max. 60 kg |

| Radiation-shielded cabinet | |

| Width x height x depth, approx | 2,000 mm × 2,700 mm × 1,800 mm |

| Weight, approx | 4t |

| Control console | |

| Width x height x depth, approx. | 1,200 mm x 1,800 mm x 1,300 mm |

| Power supply | 1 x 230 V, 50 Hz / 60 Hz |

| Power input | max. 5 kW |

| Weight, approx. | ~ 250 kg |

| Travel routes | |

| Magnification | 640 mm (max. 15 m/min) |

| Horizontal axis | 650 mm (max. 15 m/min) |

| Turntable (Ø 400 mm) | n × 360° (max. 8 rpm) |

| Hub axis | 900 mm (max. 15 m/min) |

| Tilt | ±30° (max. 7° /s) |

| Rotation | n × 360° (max. 6 rpm) |

Updating…

Automotive

| Y.Panel 0822-16 HDR premium |

| – 16 bit detector in YXLON premium-pixel quality, 1024 x 1024 pixel @ 200 µm with up to 25 fps, 512 x 512 pixel 400 µm with up to 50 fps.Suitable for film replacement for metal parts, especially in aerospace. Including housing with shielding and passive crash protection. The number of usable pixels may be reduced due to shielding. |

| – Acc. to YXLON specification, digital flat-panel detectors with premium grade quality show no “Center Kernel Pixel” respectively “relevant Cluster” acc. to ASTM 2597. |

| PC with Y.IMAGE 2500-D + ASTM window |

| Image enhancement, analysis and storage system for digital X-ray images with fast live image display and reference image functionality. The software is installed on the system PC. Major features are: |

| – Digital detector calibration using “Multi-Gain Correction” |

| – Intelligent correction of noisy and/or non-linear detector pixel |

| – File format DICONDE |

| – Measurement and text functions |

| – Various predefined filter sets |

| The ASTM reference image functionality is activated, the images themselves are part of an additional item. |

| ASTM E2973 DVD (Aluminum and Magnesium Die Casting) |

| Digital reference images acc.to ASTM E2973 on DVD and installed on the PC. Installed images are configured for a geometric magnification of two. Images for other geometric magnifications can be compiled acc. To the standard with the ASTM software tool. |

| Laser Cross |

| The laser cross has 2 line lasers that helps to depict the location of the central beam, thus simplifies the inspection part orientation for a faster application |

| IMAGE x500 | |

| IMAGE x500 imaging software is used for image evaluation. Its proven ease-of-use design is the result of a wide range of processing tools including filters, gray value scaling, annotations, and HDR live image filter, which make image processing and evaluation very convenient. |

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |