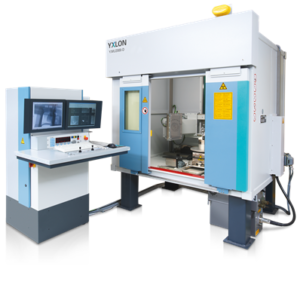

YXLON FF20 CT High Resolution Industrial CT System for Fine Parts Inspection

The YXLON FF20 CT computed tomography system is designed to achieve the best 3D inspection results at very high resolution. Whether for R&D, defect analysis, process monitoring, or CT metrology, the FF20 CT is ideally suited for inspection of a variety of very small components from the electronics and material science industries.

– Combined 2D- and 3D inspection

– 190 kV nano-focus transmission tube

– Touch operation via software platform GEMINY

– Metrology version available

- Description

- Additional information

Description

HIGHLIGHTS

YXLON 190kV nano-focus transmission tube

– Water-cooled target and coils for quick temperature balance and highest focal spot stability

– Diamond target for high power

– 4 modes for optimal adjustment of focal spot size with respect to power

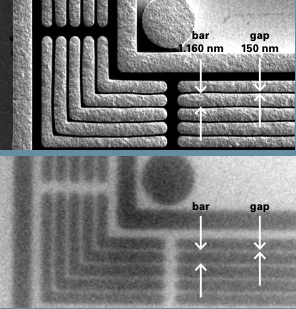

– 150 nm detail detectability (2D image)

– TXI – “”True X-ray Intensity“ for long-term stability

Granit-based manipulator

– Smallest thermal expansion and high stability of temperature

– Vibration isolation from the system by active dampers

– High-precision Heidenhain encoder on all axes

– 6 axes for utmost versatility of applications

Extremely precise turntable

– Joint development of Yxlon and Heidenhain

– Highly precise angle encoder

– Heavy load possible

– Low-maintenance, no need for compressed air supply

Selection of detectors

– Up to 430 mm x 430 mm active area for large field of view

– CsI scintillator for high local resolution and high efficiency

– Qualified acc. to ASTM E2597

– Optimized for micro-focus CT applications

ESD connections

– Safe static discharge for the work with semiconductor components

– ESD-proved construction by use of appropriate materials

ESD connections

– Safe static discharge for the work with semiconductor components

– ESD-proved construction by use of appropriate materials

Vacuum and tube cooling components

– Easy service access

– Vibration isolation from the manipulator

X-ray warning lamp

| Tube | Y.FXT 190.61 transmission tube |

| Maximum energy | 190 kV |

| Maximum power (With YXLON IQI for 2D at minimum focal spot size and HRP Target) | 80 W |

| Detail visibility | ≥150 nm |

| TXI (True X-ray Intensity – regulation of output dose for constant intensity) | yes |

| Water cooling (target and coil) | yes |

| Detector (recommended) | YXLON Panel 4343 CT |

| Active area | 432 mm x 432 mm |

| Pixel pitch | 150 μm |

| Pixel matrix | 2,880 x 2,880 |

| Frame rate | up to 15 Hz |

| Qualified acc. | ASTM E-2597 |

| Detector (alternative) | YXLON Panel 2530 |

| Active area | 249 mm x 302 mm |

| Pixel pitch | 139 μm |

| Pixel matrix | 1,792 x 2,176 |

| Frame rate | up to 30 Hz |

| Qualified acc. | ASTM E-2597 |

| Manipulation/Inspection Part | |

| FDD (Focus Detector Distance) – average, depend on detector configuration | ~ 190 mm – 790 mm |

| FOD (Focus Object Distance) – average, depend on detector configuration | ~ 0 – 575 mm |

| Loading door | motorized |

| Maximum part weight | 17 kg |

| Maximum part size | ~ 280 mm Ø x 700 mm height |

| CT – Trajectories and Scan Fields | |

| Circular scan trajectories | – continuous rotation ”QuickScan“ – start/stop scan ”QualityScan“ |

| Helical scan trajectories | – standard ”HeliExtend” – dual ”HeliExtend Dual” |

| Scan extension | – 1.8 times horizontal extension, vertical extension, combination of above |

| Further trajectories | virtual rotation axis “FlexCenter“ |

| CT field of view, std. circular scan (detector YXLON Panel 4343, collision protected, optimized for diameter) | ~ 280 mm Ø x 220 mm height |

| CT field of view, maximum (detector YXLON Panel 4343, collision protected, optimized for diameter, Standard cone beam scan with vertical field-of-view extension) | ~ 280 mm Ø x 430 mm height |

| CT Modes | QuickScan®, QualityScan, Cone-beam CT, Helical CT, virtual rotation axis, FoV extensions, Volume Crop |

| Cabinet/System | |

| Width | ~ 2,380 mm |

| Height (w/o levelling wedges) | ~ 2,180 mm |

| Depth | ~ 945 mm |

| Weight | ~ 3,400 kg |

| Manipulator design | granite base, vibration isolation with active level control, all axes equipped with Heidenhain length and angle encoders |

| Operator Desk | |

| Width | ~ 1,800 mm |

| Height | ~ 700 mm – ~ 1,200 mm, motorized |

| Depth | ~ 800 mm |

| Weight | ~ 175 kg |

| Monitor | 2 pcs., capacitive touchscreen, 1920 x 1080 pixel, 21“, as well as separate reconstruction and evaluation station with 30“ monitor |

| YXLON FF20 CT Metrology Version | |

| Conditions | |

| Features, Options | see above, but without virtual rotation axis “FlexCenter“ |

| Air conditioning inside cabinet | yes, temperature range referring to VDI 2627 measuring room quality class 3 |

| Systems ambient conditions | Measuring room quality class 4 |

| Measuring accuracy | |

| MPESD | 3.9 μm + L/75 [L=mm] |

Updating…

Typical applications for computed tomography are

– Research and development

– Failure analysis

– Process control

– Inspection of small serial productions

– Quality assurance and material analysis – Assembly checking

– Combined DR (digital radiography) and CT inspection

The extremely compact high-resolution systems YXLON FF20 CT and FF20 CT Metrology are designed for fine to very fine parts like

– Electronic components incl. SMD

– Semiconductor packages

– Products made from new materials or new manufacturing methods, e.g. additively manufactured components, fiber-reinforced plastics

– Microsystems (MEMS, MOEMS)

– Medical objects, e.g. cannulas

Updating…

Geminy

Geminy is YXLON’s award winning user interface software running on all our latest products. The most important design goal is to help you to get the inspection task done as easily as possible. This starts with having a single software for all workflows. No matter if you run a CT inspection, perform an ad-hoc manual 2D inspection, teach or run an automatic sequence: all are based in Geminy, the one and only software program for all your needs.

Different levels of users can streamline their tasks; from the daily operator that works with preset parameters and predefined tasks, to the expert that puts these in place, you can be sure the system supports all users.

“One look at the health-monitor is enough to quickly analyze the system’s condition and performance.

In case anything is abnormal, the solution is usually just a click away.

MANUAL INSPECTION

With input from customers like you, we designed the UX20 system from the ground up for fast and easy x-ray inspection of your parts.

2D inspection is really simple: mount the part and close the door. This is fast with our safe one-button solution. The system can automatically move and show you a good starting x-ray image. The clear buttons and joysticks at the operator console let you focus on the important part, the image. Use the analysis mode to get down to the details with zoom, annotations and measurements. Creating a report of what you see is simple: just use the grading buttons on the console. The final task is to press the eject button and the system is ready for the next part.

AUTOMATIC INSPECTION

Setting up repeatable testing of a part in an inspection workflow is as easy as a manual 2D inspection. When running the automatic inspection, all non-essential interactions have been removed to create a simple teaching mode. Try it out, inspection has never been so easy.

COMPUTED TOMOGRAPHY

With the heritage of CT inspection systems like the FF35 CT, you can count on a strong suite of computed tomography features.

With ScanExtend, the wizards guide you to set up various scan-field extensions to scan even the largest parts in the system.

With FlexCenter, difficult parts or regions of interest can be set up quickly, enabling you to get your task done in the minimum time.

SYSTEM PERFORMANCE CHECKS

Sometimes, you want to know how good your x-ray inspection system really is. For that, we offer a number of performance checks referring to international standards like ASTM E1695 or VDI2630 part 1.3. Executing them is simple with our automatic workflows.

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |

| Type | Semiautomatic |