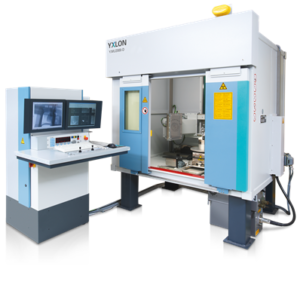

YXLON Cheetah EVO The customized standard for X-ray inspection in SMT, Semicon and laboratories

Future smart factories are all about connectivity and self-optimizing processes. Therefore, the most valuable quality control systems are the ones that offer improved automated inspections and can become an integral part of the production line. The new Cheetah EVO system is smartly designed to meet the demands of Industry 4.0, guaranteeing efficient and reliable zero fault production. It is equipped with dosage mode for especially sensitive components, has high-load capacity and a larger detector size for utmost flexibility. With the new FF CT Software, it enables optimized automated X-ray and CT industrial quality inspections, delivering even more accurate results. It is the outcome of Yxlon’s constant need for innovation and it is here to empower you today and in the future.

- Description

- Additional information

Description

HIGHLIGHTS

ONE CLICK PHILOSOPHY

One-click solutions make it easy to perform the advanced manipulations required for fast and reliable X-ray inspection. Such as:

– Click & Center

– Frame & Zoom

– PowerDrive

– Zoom+

These functions guarantee constant-intensity magnification without tube adjustments or software interpolation, and can be carried out with one simple click.

MULTI AREA VOID CALCULATION (MAVC)

Today’s soldering connections are getting more and more complex. QFNs and other bottom-terminated devices can only be inspected using x-ray. Faulty or missing solder joints and large areas of voiding are reliably detected, and MAVC helps analyze voids in complex soldering designs. With just four parameters to adjust, setup is quick, simple, and cost-efficient. Results are consistent, repeatable, and accurate.

EXTENDED BGA INSPECTION

With Cheetah EVO, you can quickly select and index individual balls, either manually or using automatic grid detection. A wizard guides you step-by-step through the workflow and ensures perfect accurate and repeatable results. Plus, the feature allows multiple operators to run the same inspection routines.

eHDR-INSPECT

To ensure highest product quality, the eHDR filter highlights complex structures with just one click. Thanks to our advanced software and enhanced 16-bit gray scale values, it detects even the slightest variances in gray scale, so that no defect will be missed. This allows you to easily see faults that were invisible before.

EXTENDED ADR INTERFACE

Cheetah EVO software can be tailored to individual requirements, with operators free to define their own specific analysis. This also includes customized algo- rithms.

| General Product Features | |

| Time to first image (typ.) | ~ 10 s |

| Reconfiguration time (typ.) | < 60 s |

| Acquisition time (Quick Scan) for 2000 projections | ~ 3.15 min |

| Reconstruction time (Quick Scan) for 2000 projections | ~ 1.55 min |

| Acquisition time (micro3Dslice Semicon) for 120 projections | ~ 1.45 min |

| Reconstruction time (micro3Dslice Semicon) for 120 projections | ~ 0.30 min |

| Access for sample loading | large automated door (690 x 650 mm) |

| Cabinet window | 520 x 370 mm |

| Monitor | 27” Ultrasharp, wide viewing angles |

| Zoom+ | yes |

| PowerDrive | yes |

| Image stabilization | air suspension |

| 3D modes | – Laminography (micro3Dslice) – CT Quick Scan – Quality Scan |

| Manipulation | |

| Manipulation control | via mouse or joystick |

| Manipulation axes | X,Y,Z(D) |

| Oblique viewing | +/-70° (140°) |

| X-ray inspection system | |

| Max. dose rate ( at 100 mm distance to the cabinet surface) | < 1μSv/h |

| Inspection parts | |

| Max. part size | 800 x 500 mm (31“ x 19“) |

| Max. radiographic area | 460 x 410 mm (18“ x 16“) |

| Max. part weight (standard) | 5 kg |

| Max. part weight rotation | 2 kg |

| Max. part weight (high load capacity) | 20 kg |

| X-ray source | XT-160.50 Microfocus | FXT-160.51 Multifocus |

| Target | transmission | transmission |

| Voltage range | 20 – 160 kV | 20 – 160 kV |

| Current range | 0.001 – 1.0 mA | 0.001 – 1.0 mA |

| Tube power | max. 64 W | max. 64 W |

| Target power | max. 15 W | max. 15 W |

| Target material | Tungsten | Tungsten |

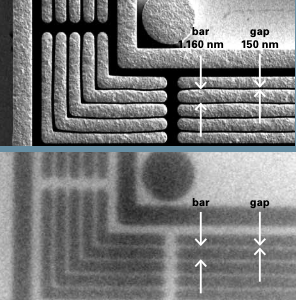

| Detail detectability | 0.75 μm | < 0.3 μm |

| X-ray intensity control | TXI | TXI |

| Image Chain | ||

| Geometric magnification | ~ 3,000 x | ~ 3,000 x |

| Total magnification | ~ 384,000 x | ~ 384,000 x |

| Spatial Resolution | 1.5 μm | 0.6 μm |

| Detector | Y.Panel 1308 | Y.Panel 1313 | ORYX 1616 |

| Max. resolution (Pixel) | 1004 x 620 | 1004 x 1004 | 1276 x 1276 |

| Pixel size | 127 μm2 | 127 μm2 | 127 μm2 |

| Pixel area | 128 mm x 79 mm | 128 mm x 128 mm | 162 mm x 162 mm |

| A/D transformer | 16 bit | 16 bit | 16 bit |

| Dimensions (w x d x h) | 1,650 x 1,400 x 2,050 mm |

| Weight | 2,200 kg |

– Upgraded YXLON Cheetah EVO system with advanced features to reach new heights in speed, image quality and reliability. Smartly designed to meet the demands of Industry 4.0, the Cheetah EVO deliver efficient and reliable, zero fault production.

– The Cheetah EVO system includes new advanced features. With a comprehensive suite of capabilities, the innovative Cheetah EVO enables you to keep up with the demands of next generation technologies.

– Cheetah EVO has an optional ORYX 1616 detector with an expanded field of view of 50% larger than the standard version, allowing to see more and do more. Combined with Cheetah’s improved automated processes, it requires fewer steps, enhance productivity. The technologically advanced ORYX 1616 is designed with high sensitivity to deliver high quality imaging with less dose. An optional dose reduction kit is available to further reduce the dose rate on sensitive components by using filters and a collimator. Due to the detector’s enhanced radiation resistance, you will also benefit from its long product life.

– The Cheetah EVO is equipped with the best laminography (micro3Dslice) on the market today. Its 3D visualization capabilities allow for quick and easy failure analysis. Optimally suited for large and complex PCBs, Cheetah EVO also enables non-destructive inspection of large areas, providing a substantial cost and time saving over micro-sectioning.

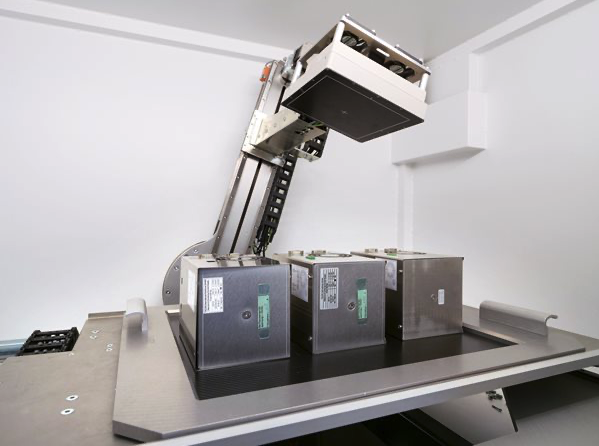

– When it comes to the heavy lifting, Cheetah EVO has an optional high load capacity of up to 20 kg allowing you to inspect several parts at the same time, as well as inspect electronic interconnects in fixed packages for the e-vehicles market.

– Cheetah EVO has integrated workflows on the FGUI interface.FF CT Software is designed to start automatically for faster reconstruction and visualization. It produces the most realistic, vivid visualization available today. That’s due to its unique ability to render 3D cinematic images with a preset selection of transfer functions (TF).

– The visualization of laminographic volumes has the same high quality as CT volumes, without the added complexity. With laminographic volumes, you can achieve clear visual fault detection with less artifacts. The new FF CT Software enables optimized automated X-ray and CT industrial quality inspections, delivering even more accurate results.

| Mains connections | 230 V ± 10% AC, 50/60 Hz, 1 Phase, neutral and ground conductor |

| Fuse protection | 16 A |

| Max. power consumption | 2.5 kVA |

SMT inspections:

– PCBs

– SMT and PTH assemblies

– IGBTs

Semicon inspections:

– Wafer inspection

– 3D integrated circuit joints

– Micro-bumps

– Sensors

– MEMS and MOEMS

– TSVs

Laboratory inspections:

– Batteries

– Connectors

– Various hard-to-see electronics components

– Medical material

– Military and space electronics

Updating…

FF CT Software

– Integrated workflow in the operator user interface

– Realistic, vivid visualization due to individual 3D cinematic renderers

– Preset selection of transfer functions (TF)

– Jitter correction

– Best-in-class reconstruction algorithms

– the visualization of laminographic volumes have the same High quality as CT volumes

– Artifact reduction such as BHR (Beam Hardening reduction), BHC (Beam Hardining correction), Ring Artifact reduction, Noise reduction Volume etc.

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |

| Type | Semiautomatic |