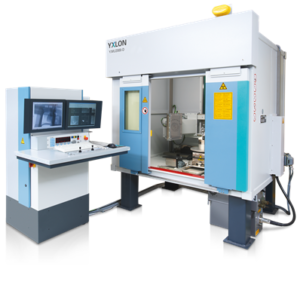

YXLON FF85 CT High Resolution Industrial CT System for a Wide Sample Spectrum

The YXLON FF85 CT computed tomography system with dual tube configuration is designed to achieve extremely precise inspection results across a wide variety of material types and parts size. With a combination of state-of-the-art hardware and innovative software, the FF85 CT supports one of the most diverse application spectrums in the X-ray and CT industry.

CT system with new dimensions in flexibility, versatility, and modularity

Extensive range of applications

Intuitive Geminy graphical user interface with touch screen operation

- Description

- Additional information

Description

HIGHLIGHTS

Extensive range of applications using up to 600 kV minifocus and a up to 300 kV directional microfocus tubes

‘Expanded inspection envelope with horizontal field of view extension, Helical and dual Helical CT techniques

Increased versatility via high precision manipulation with up to 7 axes

Clear health status indication of the system condition via Health Monitor

Flexible ROI CT scanning thanks to virtual rotation axis

Revolutionary inspection sequence creation using icons

Intuitive touchscreen operation

| X-ray components | ||

| X-Ray tube 1 | Microfocus tube 225 kV | Microfocus tube 300 kV |

| X-ray tube type | Open, unipolar, micro-focus | Open, unipolar, micro-focus |

| Maximum energy | 225 kV | 300 kV |

| Maximum power | 320 W | 350 W |

| Target type | Reflection target | Reflection target |

| Detail visibility (With JIMA resolution test pattern for 2D at minimal focal spot size) | ≥ 4 μm | ≥ 4 μm |

| X-Ray tube 2 | Minifocus tube 450 kV | Minifocus tube 600 kV |

| X-Ray tube type | Sealed, bipolar, metal-ceramic, mini-focus | Sealed, bipolar, metal-ceramic, mini-focus |

| Maximum energy | 450 kV | 600 kV |

| Focal spots | 0.4 mm / 1.0 mm | 0.7 mm / 2.0 mm |

| Maximum power | 700 W / 1500 W | 700 W / 1500 W |

| Target type | Reflection target | Reflection target |

| Detectors | ||

| Detector 1 | Flat Panel Detector 4343HE | Flat Panel Detector 4343N |

| Scintillator | Gadox | Gadox, CsI |

| Maximum energy | 16,000 kV | 450 kV |

| Active area | 427 mm x 427 mm | 432 mm x 432 mm |

| Pixel pitch | 139 μm | 150 μm |

| Pixel matrix | 3,072 x 3,072 | 2,880 x 2,880 |

| Maximum frame rate | 25 fps (3×3 binning) | 60 fps (4×4 binning) |

| Dynamic range | 16 bit | 16 bit |

| Detector 2 | Line Detector Array CTScan 3-620 | Line Detector Array CTScan 3-780 |

| Scintillator | CdWO4 | CdWO4 |

| Maximum energy | 600 kV | 600 kV |

| Dynamic range | 620 mm | 780 mm |

| Pixel pitch | 254 μm | 254 μm |

| Pixel matrix | 2,432 | 3,072 |

| Maximum frame rate | 100 fps | 100 fps |

| Dynamic range | 16 bit | 16 bit |

| Manipulator Data | |||

| Configurations | Microfocus – Flat panel detector | Minifocus – Flat panel detector | Minifocus – Line detector array |

| Max. FDD (Focus-Detector-Distance) | 2,000 mm or larger on request | 2,000 mm or larger on request | 2,000 mm or larger on request |

| Maximum magnification | 300 | 10 | 10 |

| Maximum part size (Ø x h) | 1,000 mm (collision protected) x 2,000 mm or larger on request | 1,000 mm (collision protected) x 2,000 mm or larger on request | 1,000 mm (collision protected) x 2,000 mm or larger on request |

| Maximum part weight | 400 kg | 400 kg | 400 kg |

| Manipulator dimensions | 3,600 mm length x 1,450 mm width x 2,550 mm height (or more for larger manipulators) | 3,600 mm length x 1,450 mm width x 2,550 mm height (or more for larger manipulators) | 3,600 mm length x 1,450 mm width x 2,550 mm height (or more for larger manipulators) |

| Manipulator weight | 9,000 kg (or more for larger manipulators) | 9,000 kg (or more for larger manipulators) | 9,000 kg (or more for larger manipulators) |

| CT parameter | |||

| Circular scan trajectories | Continuous rotation “QuickScan“, start/stop scan “QualityScan” | Continuous rotation “QuickScan“, start/stop scan “QualityScan” | Continuous rotation “QuickScan“, start/stop scan “QualityScan” |

| Helical scan trajectories | Standard helical CT “HeliExtend”, dual helical CT “HeliExtend Dual” | Standard helical CT “HeliExtend”, dual helical CT “HeliExtend Dual” | Standard helical CT “HeliExtend”, dual helical CT “HeliExtend Dual” |

| Further trajectories | Horizontal and / or vertical scan field extension, virtual rotation axis “FlexCenter” | Horizontal and / or vertical scan field extension, virtual rotation axis “FlexCenter” | Horizontal and / or vertical scan field extension, virtual rotation axis “FlexCenter” |

| Configurations | Microfocus – Flat panel detector | Minifocus – Flat panel detector | Minifocus – Line detector array (Line Detector Array CTScan 3-780) |

| CT field of view (circular, Ø x h) (larger values for larger manipulators) | 355 mm x 305 mm | 365 mm x 325 mm | 605 mm x 990 mm |

| CT field of view (vertical & horizontal scan field extension, Ø x h) (larger values for larger manipulators) | 680 mm x 1,300 mm | 710 mm x 1,085 mm | 980 mm x 990 mm |

| Enclosure data | ||

| Maximum shielded energy | 450 kV | 600 kV |

| Enclosure dimensions (l x w x h) (larger values for larger manipulators) | 5,150 mm x 2,650 mm x 2,880 mm | 5,150 mm x 2,650 mm x 2,880 mm |

| Enclosure weight (larger values for larger manipulators) | 31,000 kg | 52,000 kg |

| Loading door size (w x h) (larger values for larger manipulators) | 1,000 mm x 2,200 mm | 1,000 mm x 2,200 mm |

| Internal crane | Optional, maximum load 250 kg | Optional, maximum load 250 kg |

| Operator desk | |

| Width | ~ 1,800 mm |

| Height | ~ 700 mm – ~ 1,200 mm, motorized |

| Depth | ~ 800 mm |

| Weight | ~ 175 kg |

| Monitor | 2 pcs, capactive touchscreen, 1,920 x 1,080 pixel, 21″, as well as separate reconstruction and evaluation station with 30″ monitor |

Easily combine the 2D Highly-Dynamic Radioscopy (HDR) and 3D CT inspection tasks into one sequence and graphically create your individual imaging chain via drag and drop icons.

Use Yxlon’s helical CT scanning HeliExtend and HeliExtend Dual for tall parts, create an accurate image without the need of stitching and reduce artifacts for an accurate, brilliant image.

Further expand the bandwidth of inspection parts by the use of ScanExtend, the Yxlon feature for horizontal and/or vertical field-of-view extension.

“Free to inspect any region of interest in detail without having

to reposition the part physically. You even don’t need to adhere to any sample positioning techniques, because FlexCenter recognizes your part and defines the rotation axis itself.

Can apply software improvement tools: ScatterFix, Beam Hardening Reduction (BHC), Metal Artifact Reduction (MAR)

Updating…

– research and development

– first article inspection

– dimensional measurement

– small series inspection

– failure analysis

– defect and material analysis

– assembly checks

WHICH ITEMS AND MATERIALS ARE ESPECIALLY SUITABLE FOR THE YXLON FF85 CT?

– aluminum, steel and super alloy components

– additive manufacturing samples

– fiber-reinforced composites

– plastic injection molded parts

– historical art and archeological objects

– geological samples

– biological samples

– mechatronic modules

Updating…

Geminy

Geminy is YXLON’s award winning user interface software running on all our latest products. The most important design goal is to help you to get the inspection task done as easily as possible. This starts with having a single software for all workflows. No matter if you run a CT inspection, perform an ad-hoc manual 2D inspection, teach or run an automatic sequence: all are based in Geminy, the one and only software program for all your needs.

Different levels of users can streamline their tasks; from the daily operator that works with preset parameters and predefined tasks, to the expert that puts these in place, you can be sure the system supports all users.

“One look at the health-monitor is enough to quickly analyze the system’s condition and performance.

In case anything is abnormal, the solution is usually just a click away.

MANUAL INSPECTION

With input from customers like you, we designed the UX20 system from the ground up for fast and easy x-ray inspection of your parts.

2D inspection is really simple: mount the part and close the door. This is fast with our safe one-button solution. The system can automatically move and show you a good starting x-ray image. The clear buttons and joysticks at the operator console let you focus on the important part, the image. Use the analysis mode to get down to the details with zoom, annotations and measurements. Creating a report of what you see is simple: just use the grading buttons on the console. The final task is to press the eject button and the system is ready for the next part.

AUTOMATIC INSPECTION

Setting up repeatable testing of a part in an inspection workflow is as easy as a manual 2D inspection. When running the automatic inspection, all non-essential interactions have been removed to create a simple teaching mode. Try it out, inspection has never been so easy.

COMPUTED TOMOGRAPHY

With the heritage of CT inspection systems like the FF35 CT, you can count on a strong suite of computed tomography features.

With ScanExtend, the wizards guide you to set up various scan-field extensions to scan even the largest parts in the system.

With FlexCenter, difficult parts or regions of interest can be set up quickly, enabling you to get your task done in the minimum time.

SYSTEM PERFORMANCE CHECKS

Sometimes, you want to know how good your x-ray inspection system really is. For that, we offer a number of performance checks referring to international standards like ASTM E1695 or VDI2630 part 1.3. Executing them is simple with our automatic workflows.

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |

| Type | Semiautomatic |