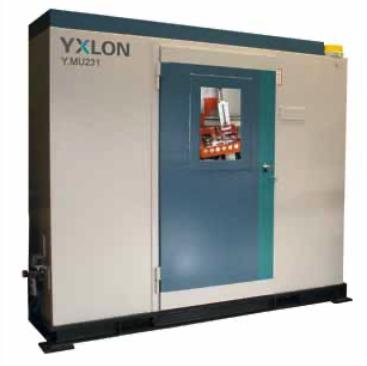

YXLON MU231 The World’s Most Popular X-ray Inspection System for Alloy Wheels

The YXLON MU231 inline wheel inspection X-ray system for alloy casting wheels, offers high-speed reliable inspection at the highest uptime. The automatic defect recognition guarantees maximum efficiency and well documented, objective quality assessment results.

High product throughput and system uptime are of primary importance when cast aluminum disc wheels are inspected on a production line using X-rays. The unique shuttle conveyor technology contained in the Y.MU231 along with its patented L-chains provide for short cycle times and low amounts of downtime. As with all X-ray equipment from YXLON, the image quality is first-rate.

Using optional Y.AI software the system can work on a fully automatic basis without having an operator run the system. The high degree of repetitive accuracy ensures a minimum rate of pseudo-rejects. A regular monitoring of image quality guarantees consistent inspection quality. As a result, inspection decisions are made with certainty.

The systems work on a cross-linked basis and generate extensive statistics in real time. This information is utilized to stabilize and improve the casting process itself.

YXLON. X-ray technology at its best.

- Description

- Additional information

Description

HIGHLIGHTS

The most successful X-ray system in its class

‘High product throughput

High system uptime

Easy, intuitive operation

| Inspection items | Y.MU231 | Y.MU231 XL |

| Wheels: | 4J x 12″ to 12J x 20″ | 4J x 12″ to 12J x 24″ |

| Height, incl. sprue (max.) | 350 mm | 400 mm |

| Diameter (max.) | 550 mm | 650 mm |

| Weight (max.) | 30 kg | 50 kg |

| Inspection item temperature | 5° C – 100° C | 5° C – 100° C |

| Radiation-shielded cabinet | Y.MU231 | Y.MU231 XL |

| Service doors | 2,000 mm x 1,000 mm | 2,000 mm x 1,000 mm |

| Leaded-glass pane | 400 mm x 600 mm | 400 mm x 600 mm |

| Connection height conveyor system | 800 mm | 800 mm |

| Dimensions (W x H x D) | 3,150 mm x 2,300 mm x 2,400 mm | 4,500 mm x 2,250 mm x 2,800 mm |

| Weight | 7,500 kg | 7,000 kg |

| X-ray system | |

| Model | Y.TU160-D05 |

| Tube voltage | 8 kV – 160 kV |

| Tube current (max. at 160 kV) | 6,25 mA |

| Power output (max.) | 1.000 W |

| Detector Active Area | Image intensifier: 9″ and 12″ diameter |

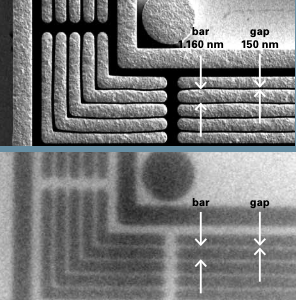

| Pixel Pitch | Analog image intensifier: 300 [µm] Digital image intensifier: 200 [µm] |

| Bit Depth | Analog image intensifier: 8 [bit] Digital image intensifier: 12 [bit] |

| Focal-spot size (EN12543) | 1.0 mm x 1.0 mm |

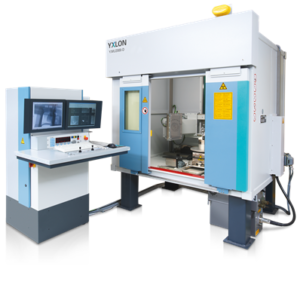

With the MU231 you’ll achieve high uptime (more than 95%) with minimum maintenance cost. Unique shuttle-conveyor system and patented L-chain allows for short cycle times, e.g. 26 sec for a typical 6Jx16” wheel (MU231XL: 28 sec) with digital image intensifier. And automatic inspection with AI software (optional) gives you reliable and objective inspection decisions with a minimal pseudo reject rate.

Supports a wide range of wheel sizes:

4J x 12‘‘ to 12J x 20‘‘ wheels (maximum diameter: 560 mm) of a maximum width of 350 mm and up to 25 kg.

MU231 XL is available for wheels of up to 12J x 24’’(maximum diameter: 650 mm) of a maximum width 400 mm and up to 50 kg.”

Individual imaging chain options are available:

Digital detector array YXLON panel 460 for highest quality image and the most stable inspection results

Economic analogue and digital imaging intensifiers (available in 9 and 12” diameter)

MU231 can be fully integrated into your plants processes. The casting station delivers the X-ray results straight to the casting for fast feedback on new batches. The statistics server provides data for continuous improvement of the production quality. And the review station allows you to maximize inspection efficiency.

| Environmental temperature | 5°C–35°C |

| Air humidity (max.) | 80%, not condensing |

| Power connection | 3 N PE 400 VAC +10% – 15%, 50/60 Hz |

| Energy consumption | 4.5 Kw |

| Compressed air | 4,000 l/h, min. 5 hPa |

Automotive industry

Y.AI for fully automatic X-ray inspection

L-chain for the highest upring and accurate positioning

Automatic wheel recognition system

Statistics server to improve the casting process

Step wedge for regular auditing of image quality

Calibration wheel for comparing multiple systems

Digital camera for image intensifier

9-inch Y.XRS233 image intensifier

12-inch Y.XRS303 image intensifier

Motorized magnification axis

Y.AI for fully automatic inspection

Y.AI software provides an objective, precise and repeatable inspection of X-ray images at a speed far superior to the abilities of a human operator. Meanwhile nearly all systems delivered include this option.

Each region of the wheel can be tested while applying different specifications for inspection. The quality called for in each particular region is attained while achieving a minimum of pseudo-rejects.

Extensive statistics regarding wheel inspection are generated via the software. They can be retrieved in real time and merged on a statistics server. This data helps to enable targeted interventions within the casting process. After a short time, the success of such interventions can already be controlled on the next wheel.

Additional information

| Manufacturer | Yxlon |

|---|---|

| Origin | Germany |

| Type | Automatic |