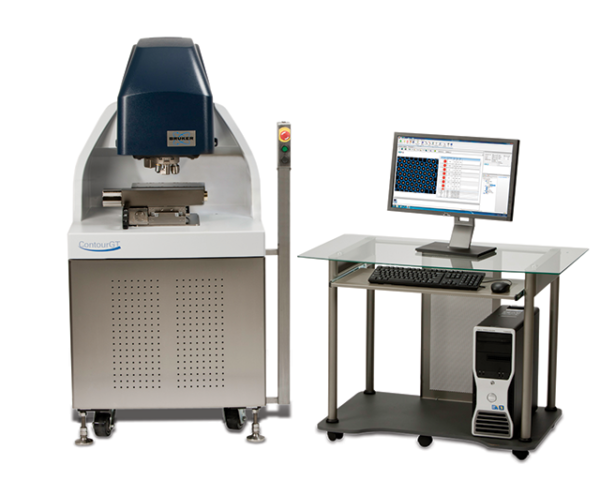

3D OPTICAL PROFILOMETER ContourGT-X

The ContourGT-X 3D Optical Profiler provides the highest performing non-contact surface measurements for laboratory research and production process control. Incorporating ten generations of white light interferometry (WLI) innovation and design, this metrology system delivers the highest vertical resolution over the industry’s largest field of view. Key features include full automation and a production interface, a large motorized XYZ stage, tip/tilt in the head, and an integral air isolation table. Designed from the ground up for the most demanding R&D, quality assurance, and process quality control needs, the ContourGT-X offers the ultimate in gage-capable 3D optical accuracy and robustness.

- Mô tả

- Thông tin bổ sung

Mô tả

HIGHLIGHTS

Full automation

Provides fastest, and easiest nanometer-scale measurements.

Customizable production interface

Delivers streamlined process workflows, automated mapping, and load measurement recipes.

Self-calibrating laser reference

Ensures best production metrology, repeatability and robustness.

Applications:

– Polymer substrates Roughness & waviness measurements

– Defect Detection and Analysis on Flexible Film

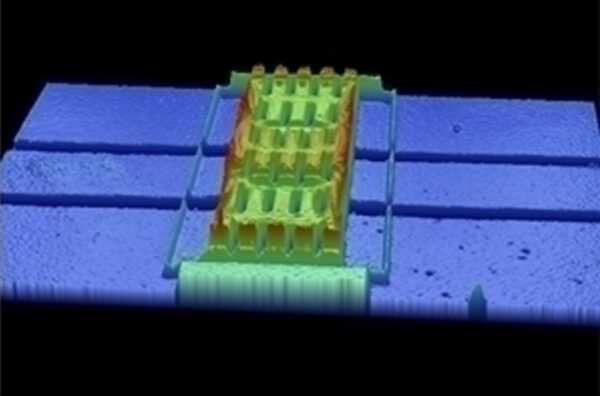

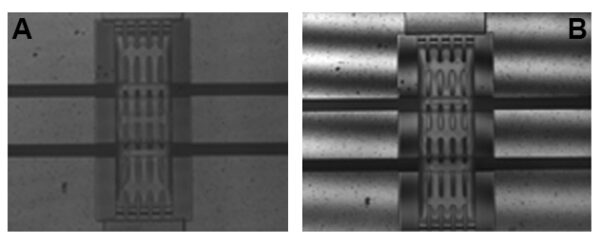

– MicroElectroMechanical Systems (MEMS)

– Optical Profiling Advantages for MEMS manufacture

– Roughness Measurement

– Step Height Measurement

– Dynamic Measurement (DMEMS)

| – Max. Scan Range | >10 mm |

| – RMS Repeatability | <0.03 nm; 0.02 nm typical (motor); 0.004nm (PZT) |

| – Lateral Resolution | 0.38 µm min (Sparrow criterion); 0.26 µm (with AcuityXR®) |

| – Step Height Accuracy | <0.75% |

| – Step Height Repeatability | <0.1% 1 sigma repeatability |

| – Max. Scan | 114 µm / sec (with standard camera) |

| – Sample Reflectivity | 0.05%-100% |

| – Max. Sample Slope | Up to 40° (shiny surfaces); Up to 87° (rough surfaces) |

| – Sample Height | Up to 100 mm |

| – Sample Weight | Up to 23 kg (50 lb) |

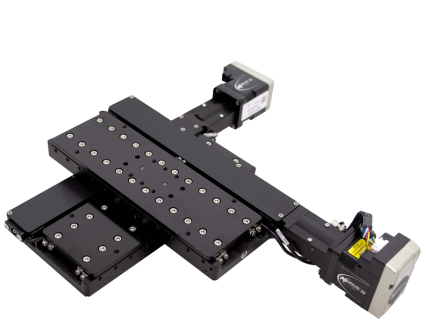

| – XY Sample Stage | 300 mm (12in.) automated; 0.5 µm encoders |

| – Z Focusing | 100 mm (4 in.) automated |

| – Tip/Tilt Function | ±6° automated in head |

| – Optical Metrology Module | Patented dual-LED illumination; Single-objective adapter; Optional automated or manual turret |

| – Objectives | Parfocal: 2.5x, 5x, 10x, 20x, 50x, 115x LWD: 1.5x, 2x, 5x, 10x TTM: 2x, 5x,10x, 20x Brightfield: 2.5x, 5x, 10x, 50x |

| – Available Zoom Lenses | 0.55, 0.75x, 1x 1.5x, 2x auto-sensing modules |

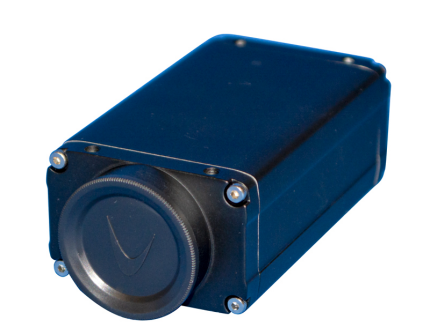

| – Camera | Standard monochrome: 640×480; High-resolution monochrome (option): 1376×1032 Color (option): 640×480; High-resolution color (option): 1376×1032 |

| – Software System | Vision64 Analysis Software on Windows 7 64 bit OS |

| – Software Packages | Production interface; AcuityXR; Annular Analysis; High Speed AF; Optical Analyses; Advanced Image Processing; TCP/IP; Thick and Thin Film; MatLab scripts |

| – XY Automation | Automated stitching, scatter, and grid automation |

| – Calibration | Via traceable step standards; Optional auto and continuous internal laser signal |

| – System Footprint | 852 mm (W) x 793 mm (D) x 1608 mm (H) |

| – Weight | 493 kg (1084 lb) |

| Production-Ready Design and Reliability ContourGT-X incorporates Bruker’s patented tip/tilt head, a patented self-calibrating laser reference, integrated pattern recognition, and a host of other proprietary interferometry innovations to deliver extremely accurate surface metrology with high throughput. The system’s automation-ready configuration enables rapid optimization in almost any production environment with features ranging from an air table stabilizer kit for enhanced X, Y, Z wafer placement accuracy and PDU, EMO, and vacuum systems for integration to modified vacuum chucks for autoloader end-effector compatibility.High-Accuracy Stage for Highest Resolution Imaging The ContourGT-X motorized XY stage provides 12-inch encoded movement in the X and Y directions. The stage supports automated routines, such as multiple-point data collection, as well as stitching capability for large-area analyses. The 0.5 micron encoders provide reliable, repeatable automation and sample positioning. Sample positioning is made easy for operators by intuitive joystick and software interface controls.Intuitive Surface Measurement and Analysis Software Bruker’s Vision64® Operation and Analysis Software provides the industry’s most functional and streamlined graphical user interface, combining intelligent architecture with intuitive visual workflow and extensive user-defined automation capabilities for fast and comprehensive data collection and analysis. An Advanced Production Interface allows adaptation of ContourGT-X to almost any production environment and automated process. The interface provides tools to customize process workflow, automate mapping, and load measurement recipes. |

Updating…..

| Key application areas: • Automotive/Aerospace • Data Storage • Solar • MEMS • Semiconductor • LED, Optics • Medical • Precision Machining/Tribology |

| – Polymer substrates Roughness & waviness measurements |

| – Defect Detection and Analysis on Flexible Film |

| – MicroElectroMechanical Systems (MEMS) |

| – Optical Profiling Advantages for MEMS manufacture |

| – Roughness Measurement |

| – Step Height Measurement |

| – Dynamic Measurement (DMEMS) |

AcuityXR

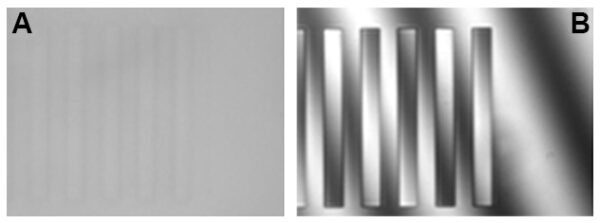

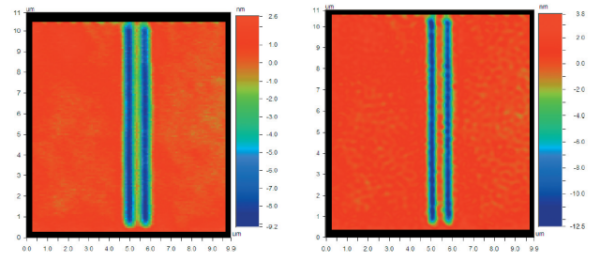

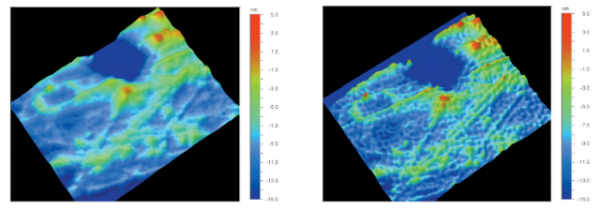

AcuityXR® combines unique, patent-pending Bruker hardware and software technology to enable select Contour 3D optical surface profilers to break the optical diffraction limit and deliver lateral resolutions previously considered unattainable with conventional optical microscopy techniques. It works on smooth surfaces where the phase of the reflected light is used to calculate surface height from the white-light-interferometric signal, improving sharpness, clarity, and definition of scratches, defects, and surface texture. Additionally, dimensional repeatability on nanoscale structures is improved by a factor of 5X.

|  |

Through Transmissive Media

“Enables high-resolution measurements through protective packaging, environmental chambers and other dispersive materials

– Measure samples through glass and other materials up to 3mm thick

– Innovative illumination enables up to 40x measurements

– Universal housing supports multiple magnifications and compensation materials

– 20x objective offers 25:1 aspect ratio for deep trench measurements

– For MEMS, materials science, biological applications, and more”

|

|

|

|

Upgrade Your Optical Profiler

Maximize your productivity with system hardware and software upgrades

– Hardware Upgrades

+ Computer Upgrade

The new Dell Precision computer with Windows 10 and the latest version of Vision64, version 5.70 enables new measurement capabilities, improved security, and enhanced remote support.

+ Automated FOV

The three position automated FOV allows quick swapping of FOV lenses from your computer.

+ Motorized XY Stage

+ Motorized XY Stage

The 6-inch automated XY stage enables stitching and stage automation.

+ High-Resolution Cameras

Bruker offers a selection of color and monochrome cameras to meet your application needs.

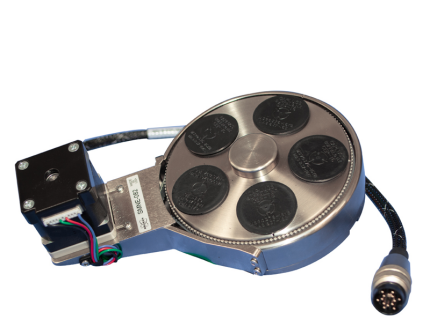

+ Automated 5-Position Turret

The automated five-position turret provides quick, efficient switching of objectives and adds objective parcentricity when used with a motorized XY stage. For use with all Bruker par-focal objectives.

+ Objectives and FOV Lenses

Increase capability of your optical profiler with Bruker objectives and FOV lenses. Bruker offers objectives with 1.5x to 115x magnifications.

– Software Upgrades

– Software Upgrades

+ AcuityXR Enhanced Resolution Measurement Mode

The AcuityXR measurement mode enhances the lateral resolution when using PSI (Phase Shifting Interferometry) or VXI measurement modes with the benefit of maintaining an equivalent field of view at higher resolution. It combines unique, patent-pending, hardware and software technology to enable select 3D Optical Surface Profilers to break the optical diffraction limit and deliver lateral resolutions that are traditionally unattainable with conventional interferometry techniques.

Advanced Production Interface

The Advanced Production Interface option significantly expands the Vision64 Production Mode with: (1) Customizable Workflow to add any number of processes prior to measurement sequence with operator prompts and instructions; (2) Data Entry Fields to prompt operators to enter process-specific information; and (3) Recipe Mapping to automatically map and load recipes based on information entered in the data entry fields.

Optical Analysis Package

The Optical Analysis software enables the use of common optical element analyses, including Zernike polynomial fitting.

SureVision Analysis Package

SureVision provides surface statistics on individual, user-defined regions within a dataset. Regions of interest are defined by customizable data templates through easy-to-use use wizards. Selected regional areas (islands) can be individually analyzed or grouped into larger regions, and a wide range of surface and height statistics can be computed for reach region. The result of each region can be analyzed in pass/fail criteria. This software supports full-automation measurements and varying material-type correction tables.

TCP/IP Runtime Control Server

This option allows external control of profilers via Vision’s TCP/IP command set.

Thick and Thin Film Measurement

This software provides the capability to measure transparent and semi-transparent films. The minimum measurable film thickness is dependent upon the film material and objective selected, and the maximum film thickness measurable is 600 µm, but is sample-dependent.

MATLAB Scripts

This option enables a set of MATLAB scripts to import and export Vision data to MATLAB for offline processing. It includes a user analysis that can export data in real time to MATLAB for runtime data analysis, and the results can be returned to Vision for display and/or logged to a database.

Vision64 MAP Imaging Topography Software

This dongle enables the use of dedicated surface imaging, analysis and metrology software for Bruker’s 3D optical microscopes.

Vision64 MAP Premium

This premium version of the dedicated surface imaging, analysis and metrology software for Bruker’s 3D optical microscopes includes 2D Advanced Surface Texture, Contour, 2D Automotive, Basic Surface Texture, SPM Extension,

3D Advanced Surface Texture, 3D Fourier & Wavelets, Color Image Overlay, Co-localization, Surface Stitching, 4D Series, Statistics, Grains & Particles modules.

Cognex Pattern Recognition

Improve your automation routine with precise and automated positioning.

Enhanced Imaging Software

Real-time visual data build up while you are scanning.

Vision64®

Bruker’s Vision64® Operation and Analysis Software provides the industry’s most functional and streamlined graphical user interface, combining intelligent architecture with intuitive visual workflow and extensive user-defined automation capabilities for fast and comprehensive data collection and analysis. An Advanced Production Interface allows adaptation of ContourGT-X to almost any production environment and automated process. The interface provides tools to customize process workflow, automate mapping, and load measurement recipes.

– Streamlined, customizable production interface

– Real-time automated measurement optimization

– Extensive library of filters and customizable analysis options

Thông tin bổ sung

| Hãng sản xuất | Bruker Nano |

|---|---|

| Xuất xứ | Đức |

| Loại | Thủ công |