3D OPTICAL PROFILOMETER NPFLEX

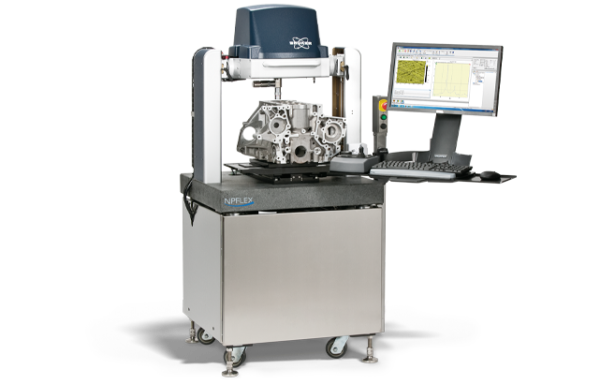

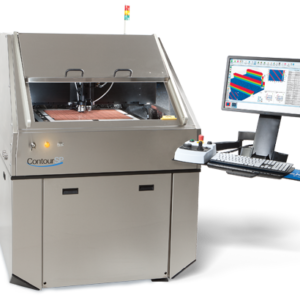

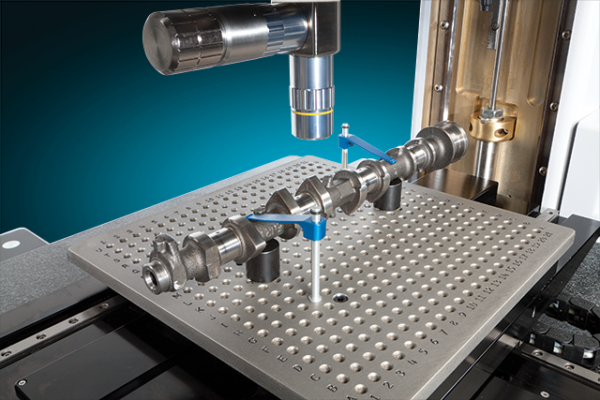

The NPFLEX 3D Metrology System offers the most flexible, non-contact, 3D areal surface characterization for such large samples as orthopedic medical implants and the larger parts in aerospace, automotive and precision machining industries. It provides data density, resolution, and repeatability beyond what is possible with contact instrumentation, making it ideal as both a complementary technology or as a stand-alone metrology solution.

- Mô tả

- Thông tin bổ sung

Mô tả

HIGHLIGHTS

Configurable hardware and software

Meet the measurement needs for nearly any sample, shape, or size.

Rugged architecture

Accommodates the rigors of manufacturing environments.

Automated measurement routines

Speed up production metrology and analysis results.

| – Measurement Capability | Non-contact, 3D, surface roughness, critical dimension, film thickness, tribology. |

| – Objectives | Super long working distance objectives: 2X, 5X, 10X, with crash mitigation assembly; Standard working distance objectives: 1.5X, 2.5X, 5X, 10X, 20X, 50X, 100X, 115X |

| – Field of View Multipliers | Super long working distance objectives: 2X, 5X, 10X, with crash mitigation assembly; Standard working distance objectives: 1.5X, 2.5X, 5X, 10X, 20X, 50X, 100X, 115X |

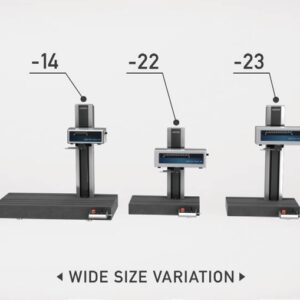

| – Measurable Sample Dimension | 350 mm H (249 mm with automated stage); 304 mm D; 304 mm W |

| – Stage Weight Load Capacity | ≤50 kg (110 lbs) |

| – Optical Assembly | Integrated computer-controlled illuminator; Closed-loop precision vertical scanner |

| – Computer System | Latest Dell PC with flat panel monitor, mounted on Ergotron mobile workstation; Production mode, built-in databasing with pass/fail for any parameter; Optional HDVSI, MATLAB/TCPIP, Film Analysis, Optical Analysis and SureVision |

| – Vertical Resolution | <0.1 nm |

| – RMS Reapeatability | 0.004 nm |

| – Step Height | 0.75% accuracy; <0.12% 1 sigma repeatability |

| – Optical Resolution | 0.33 μm |

| – Field-of-View | 7.68 × 5.76 mm max, larger with stitching |

| – Certification | CE, NRTL, T-Mark, ROHS compliant, ANSI B46.1 compliant |

| – System Footprint | 172 cm H x 77 cm D x 81 cm W (67.6 in. H x 30.4 in. D x 32 in. W) |

Unparalled Metrology Flexibility

NPFLEX is designed specifically for investigating widely varying sample sizes and shapes without damaging the sample. Insensitive to material type, the system’s WLI technology provides 3D, non-contact measurements of virtually any surface feature. A breakthrough open-gantry design affords more than 300 degrees of access to surfaces previously inaccessible or too difficult to analyze due to size or part orientation. With 13 inches (330 millimeters) of space below the objectives, there is easy accessibility to part areas that simply can’t be reached with other types of profilometers.

Customized Configurations

The NPFLEX system offers many options to customize its operation for specific applications. The Swivel Head option permits repetitive investigation of sidewalls, beveled edges, and angled surfaces. Additionally, there are several stage options available:

+ Rotational stage with optional chuck for holding fixtures

+ Theta rotating stage for sample rotation

+ Phi rotating stage for vertical sample rotation

+ Phi Roller Stage for automated positioning and rotation of smaller, cylindrical samples

+ Automated XY Stage for automated XY positioning

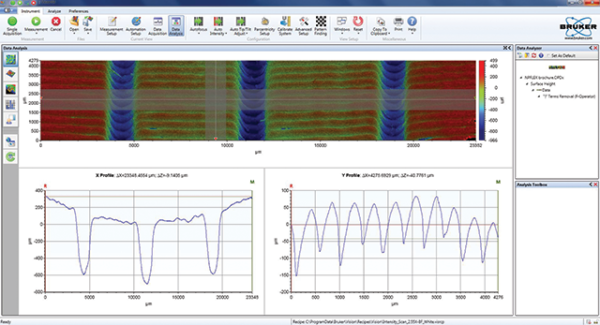

Automated Processes and Analyses

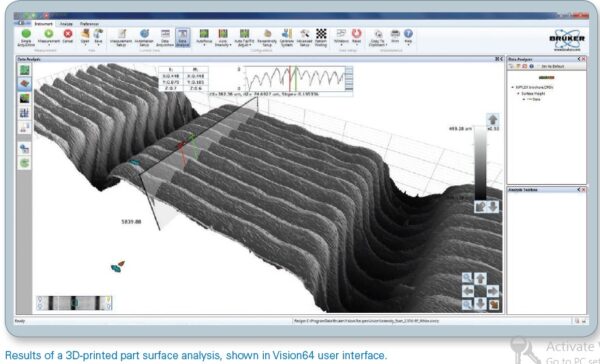

NPFLEX is powered by Vision64 software, the industry’s most functional and user-friendly graphical interface. It incorporates the familiar Windows ribbon design and toolbar functionality. Intelligent architecture enables extensive user-defined automation capabilities. Vision64’s Data Analyzer and Analysis Toolbox incorporates industry-specific analysis routines and ISO standards. Based on a typical manufacturing production flow, the interface provides tools to easily customize process workflows and automate mapping.

Updating…..

Manufacturing Process Improvement Across Diverse Industries:

• Process Development

• Production

• Quality Analysis

• Product Research & Development

• Oil Transport and Refining

• Automotive & Aerospace

• Medical

• Primary Metal Manufacturing

• Fabricated Metal Products

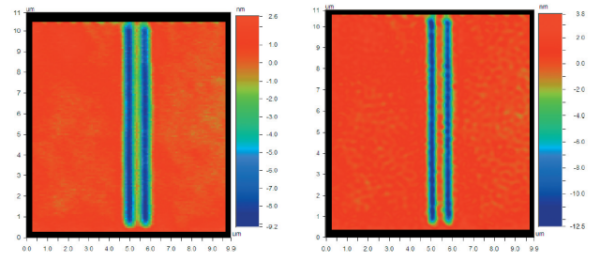

AcuityXR

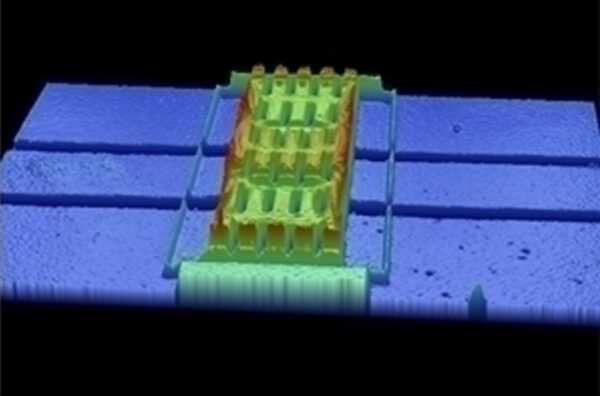

AcuityXR® combines unique, patent-pending Bruker hardware and software technology to enable select Contour 3D optical surface profilers to break the optical diffraction limit and deliver lateral resolutions previously considered unattainable with conventional optical microscopy techniques. It works on smooth surfaces where the phase of the reflected light is used to calculate surface height from the white-light-interferometric signal, improving sharpness, clarity, and definition of scratches, defects, and surface texture. Additionally, dimensional repeatability on nanoscale structures is improved by a factor of 5X.

|  |

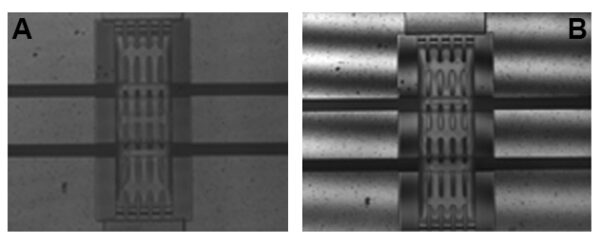

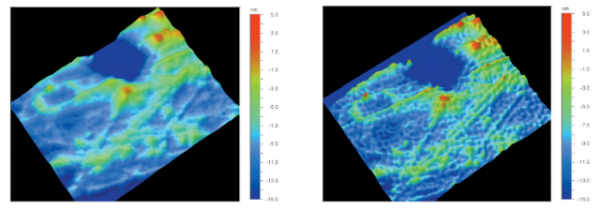

Through Transmissive Media

“Enables high-resolution measurements through protective packaging, environmental chambers and other dispersive materials

– Measure samples through glass and other materials up to 3mm thick

– Innovative illumination enables up to 40x measurements

– Universal housing supports multiple magnifications and compensation materials

– 20x objective offers 25:1 aspect ratio for deep trench measurements

– For MEMS, materials science, biological applications, and more”

|

|

|

|

Upgrade Your Optical Profiler

Maximize your productivity with system hardware and software upgrades

– Hardware Upgrades

+ Computer Upgrade

The new Dell Precision computer with Windows 10 and the latest version of Vision64, version 5.70 enables new measurement capabilities, improved security, and enhanced remote support.

+ Automated FOV

The three position automated FOV allows quick swapping of FOV lenses from your computer.

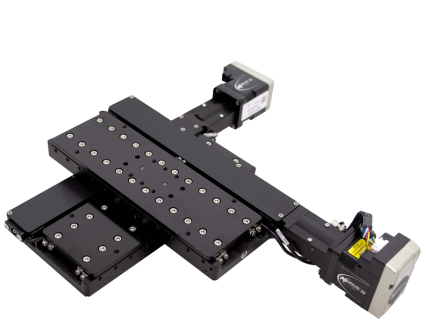

+ Motorized XY Stage

+ Motorized XY Stage

The 6-inch automated XY stage enables stitching and stage automation.

+ High-Resolution Cameras

Bruker offers a selection of color and monochrome cameras to meet your application needs.

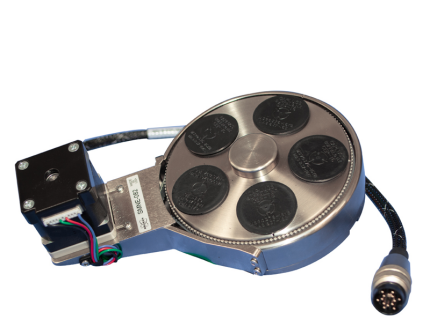

+ Automated 5-Position Turret

The automated five-position turret provides quick, efficient switching of objectives and adds objective parcentricity when used with a motorized XY stage. For use with all Bruker par-focal objectives.

+ Objectives and FOV Lenses

Increase capability of your optical profiler with Bruker objectives and FOV lenses. Bruker offers objectives with 1.5x to 115x magnifications.

– Software Upgrades

– Software Upgrades

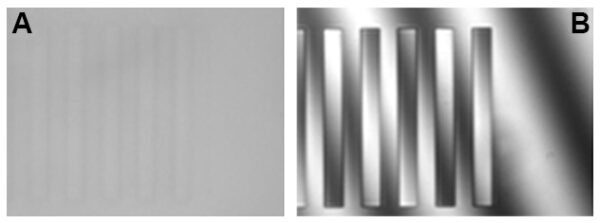

+ AcuityXR Enhanced Resolution Measurement Mode

The AcuityXR measurement mode enhances the lateral resolution when using PSI (Phase Shifting Interferometry) or VXI measurement modes with the benefit of maintaining an equivalent field of view at higher resolution. It combines unique, patent-pending, hardware and software technology to enable select 3D Optical Surface Profilers to break the optical diffraction limit and deliver lateral resolutions that are traditionally unattainable with conventional interferometry techniques.

– Computer Systems: Optional HDVSI, MATLAB/TCPIP, Film Analysis, Optical Analysis and SureVision

– Objectives: Optional through transmissive media objective kits;

Optional four-position turret

Vision64® software

NPFLEX is powered by Vision64® software, the industry’s most functional and user-friendly graphical user interface. It incorporates the familiar Windows Ribbon design and a toolbar with Windows 7 functionality and features. Intelligent architecture supports an intuitive, visual workflow and enables extensive user-defined automation capabilities.

Thông tin bổ sung

| Hãng sản xuất | Bruker Nano |

|---|---|

| Xuất xứ | Đức |

| Loại | Tự động |