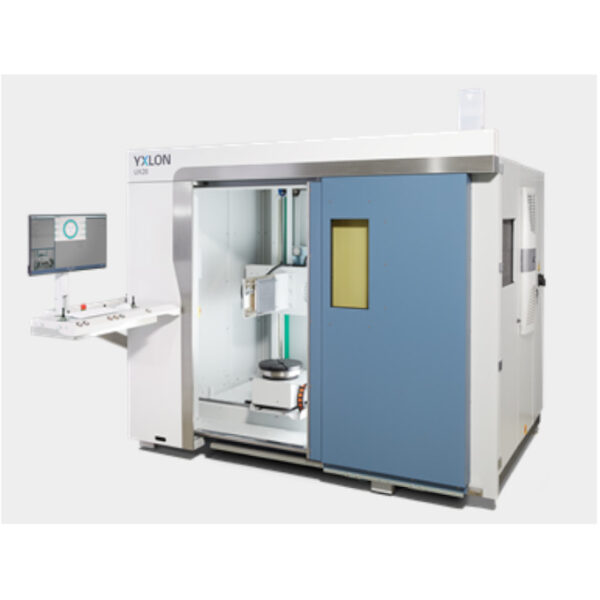

YXLON UX20 – HỆ THỐNG KIỂM TRA X-RAY VÀ CT PHỔ THÔNG CHO CÁC BỘ PHẬN VỪA VÀ LỚN

Hệ thống YXLON UX20 để kiểm tra X-quang và CT các bộ phận đúc từ trung bình đến lớn giúp công việc kiểm tra của bạn trở nên dễ dàng hơn bao giờ hết. Việc kiểm tra đặc biệt của nó cho phép các kết quả 2D và 3D trong thời gian ghi nhận.

- Mô tả

- Thông tin bổ sung

Mô tả

HIGHLIGHTS

Easy operation with Yxlon’s award winning user interface Geminy

Fast results with large inspection envelope in 2D and 3D

Modern industrial design with a compact footprint

| Cabinet | 160kV/225kV |

| Width | 2,550 mm |

| Depth | 1,770 mm |

| Height, operation | 2,350 mm |

| Height, transport | 2,150 mm |

| Dose rate, maximum (100 mm distance from the cabinet surface) | 1 μSv/h |

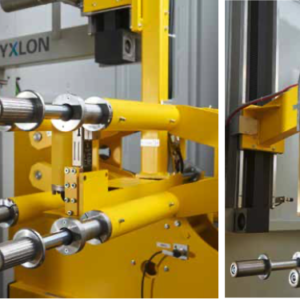

| Manipulator | |

| Maximum sample weight | 100 kg |

| Tilt angle, oblique | up to ±55 ° (45° in central beam) |

| Turntable, Ø | – 300 mm – optional 600mm t-slot turntable |

| Loading door clearance, width x height | 840 x 1,625 mm |

| Inspection envelope and x-ray detector | Y.Panel 2323HB | Y.Panel 4343DXi |

| Active area | 230 x 230 mm (1280 x 1280 px) | 430 x 430 mm (3072 x 3072 px) |

| Pixel pitch | 179 μm | 139 μm |

| Bit Depth | 16 bit | 16 bit |

| Focus-detector distance (FDD) | 900 mm | 1,150 mm |

| Part size, maximum | Ø 710 x 1,090 mm height | Ø 830 x 1,100 mm height |

| Inspection envelope 2D | Ø 710 x 1,090 mm height | Ø 800 x 1,100 mm height |

| Inspection envelope basic CT (3D) | Ø 190 x 165 mm height | Ø 340 x 280 mm height |

| Inspection envelope extended CT (requires professional analysis PC, artefacts between horizontal scans of a few mm are normal) | Ø 315 x 1,085 mm height | Ø 540 x 1,100 mm height |

| X-ray source | Y.TU160-D06 | Y.TU160-D04 | Y.TU225-D04 |

| Energy, maximum | 160 kV | 160 kV | 225 kV |

| Power, maximum | 800/1,800 W | 640/640 W | 800/1,800 W |

| Focal spot size (according to EN12543) | 0.4/1 mm | 1/1 mm | 0.4/1 mm |

| System Dimensions | 2250 x 1770 x 2350 [mm] |

| Weight | – 4,300kg for 160kV cabinet – 5,300kg for 225kV cabinet |

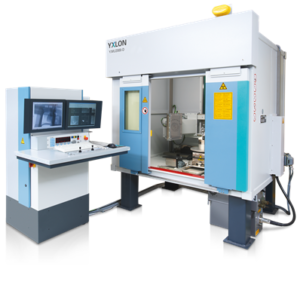

– We designed the UX20 system from the ground up for fast and easy x-ray inspection of your parts. The award-winning user interface Geminy enables an easy inspection, both for your 2D and 3D inspection needs. Our efficient workflows with automation, wizards and presets guide the user.

– Different user roles help to streamline your tasks: the expert can tweak all parameters and set up presets while less experienced users can simply execute predefined tasks. That way, you can be sure That the system is ready for your inspection needs at any time.

– One glance at the health monitor is enough to grasp the system’s condition and performance. In case anything is abnormal, the solution is usually just a click away.

– Optimized image chain with x-ray tube, detector and image processing software provide benchmark image quality, the basis for best inspection results.

– Easy inspection is the sum of many components. the operator desk, for example, has only the items That you really need. Moreover, it’s adjustable in height for ergonomic standing or sitting positions according to the user’s individual needs.

Due to its small footprint and low height, you can even place the system in narrow corners. With access from two sides, maintenance is hassle-free. even the cooler and generator are safely placed internally to improve uptime.

| Mains connection | 230 V ±10%, 50/60 Hz, 1N PE |

| Power consumption, maximum | 3.8 kVA |

| – quality assurance and material analyses |

| – failure analyses such as flaws, porosities, cracks, inclusions |

| – assembly checking |

| – measurements of inner structures |

| – inspection of small serial productions |

| – process control |

| TYPICAL INSPECTION PARTS |

| – automotive and aerospace components |

| – castings |

| – welded structures |

| – plastics |

| – special alloys |

| – ceramics |

Updating…

Geminy

Geminy is YXLON’s award winning user interface software running on all our latest products. The most important design goal is to help you to get the inspection task done as easily as possible. This starts with having a single software for all workflows. No matter if you run a CT inspection, perform an ad-hoc manual 2D inspection, teach or run an automatic sequence: all are based in Geminy, the one and only software program for all your needs.

Different levels of users can streamline their tasks; from the daily operator that works with preset parameters and predefined tasks, to the expert that puts these in place, you can be sure the system supports all users.

“One look at the health-monitor is enough to quickly analyze the system’s condition and performance.

In case anything is abnormal, the solution is usually just a click away.”

MANUAL INSPECTION

With input from customers like you, we designed the UX20 system from the ground up for fast and easy x-ray inspection of your parts.

2D inspection is really simple: mount the part and close the door. This is fast with our safe one-button solution. The system can automatically move and show you a good starting x-ray image. The clear buttons and joysticks at the operator console let you focus on the important part, the image. Use the analysis mode to get down to the details with zoom, annotations and measurements. Creating a report of what you see is simple: just use the grading buttons on the console. The final task is to press the eject button and the system is ready for the next part.

AUTOMATIC INSPECTION

Setting up repeatable testing of a part in an inspection workflow is as easy as a manual 2D inspection. When running the automatic inspection, all non-essential interactions have been removed to create a simple teaching mode. Try it out, inspection has never been so easy.

COMPUTED TOMOGRAPHY

With the heritage of CT inspection systems like the FF35 CT, you can count on a strong suite of computed tomography features.

With ScanExtend, the wizards guide you to set up various scan-field extensions to scan even the largest parts in the system.

With FlexCenter, difficult parts or regions of interest can be set up quickly, enabling you to get your task done in the minimum time.

SYSTEM PERFORMANCE CHECKS

Sometimes, you want to know how good your x-ray inspection system really is. For that, we offer a number of performance checks referring to international standards like ASTM E1695 or VDI2630 part 1.3. Executing them is simple with our automatic workflows.

Thông tin bổ sung

| Hãng sản xuất | YXLON |

|---|---|

| Xuất xứ | Đức |

| Loại | Bán tự động |